Coagulating point determinator and its determination method

A freezing point and measuring instrument technology, applied in the field of thermal analysis, can solve the problems of poor repeatability of the measurement method and large data error, and achieve the effects of accurate freezing point measurement, improving accuracy and expanding the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

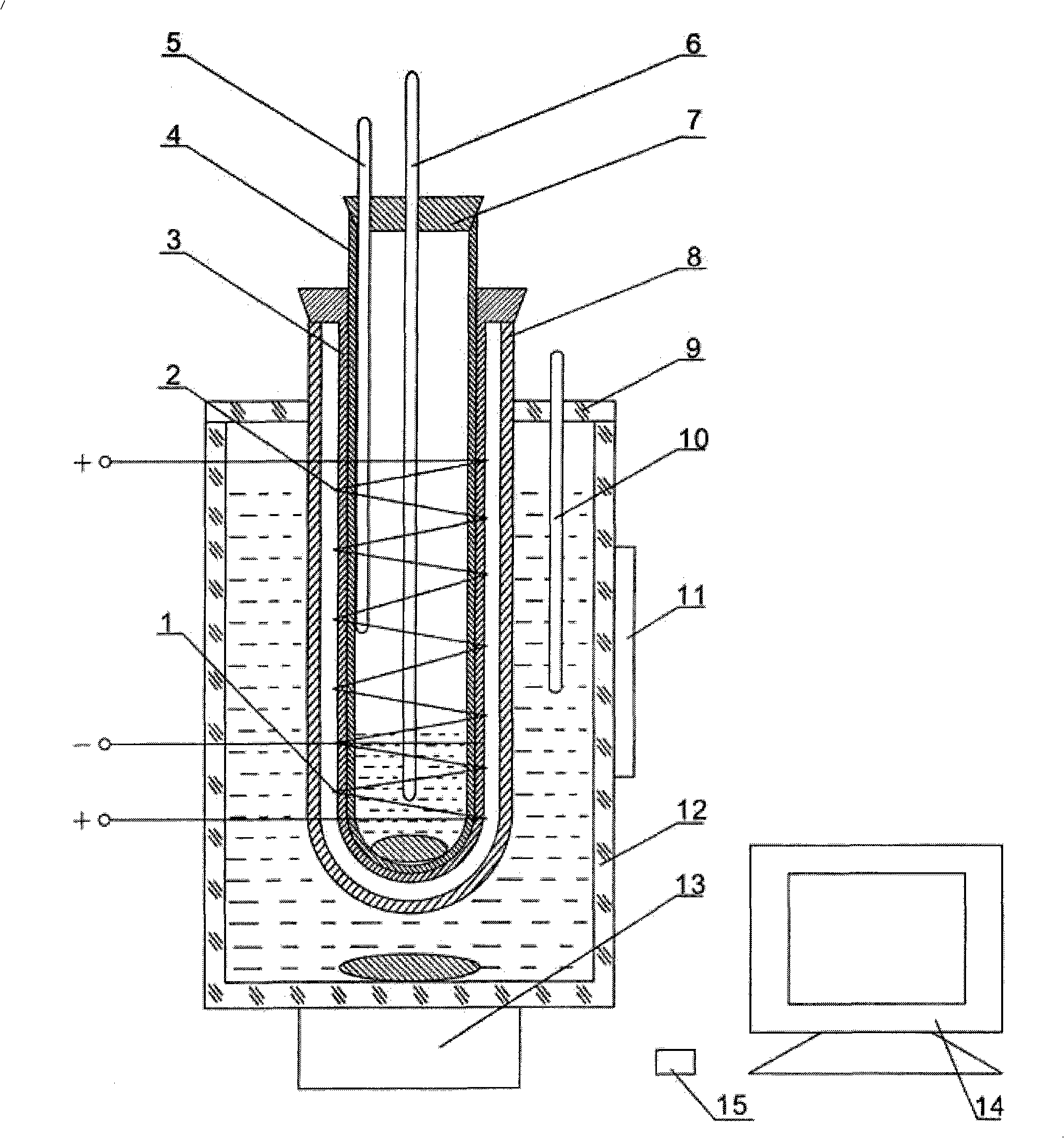

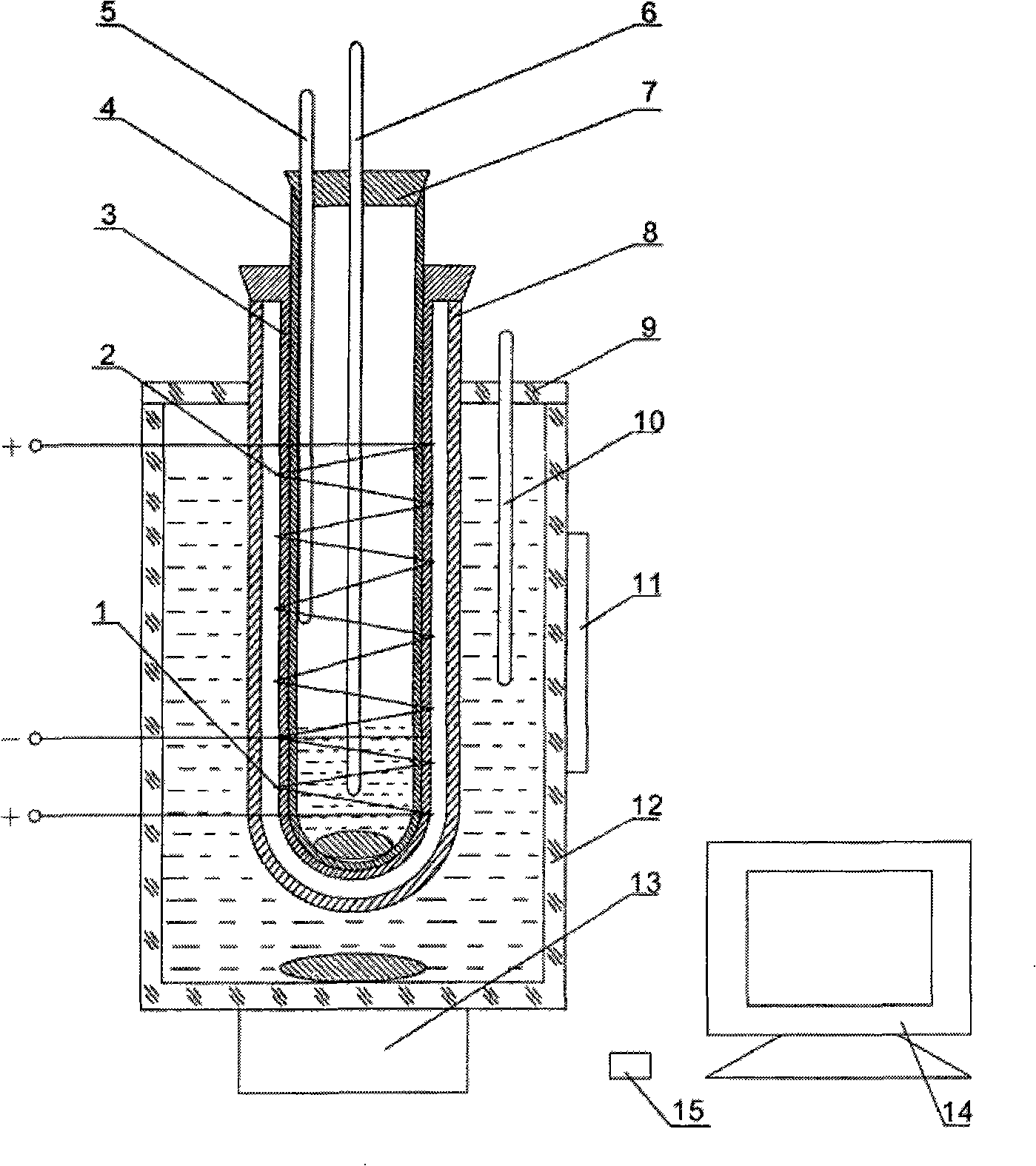

[0033] exist figure 1 Among them, the freezing point measuring instrument of this embodiment consists of a lower heating resistance wire 1, an upper heating resistance wire 2, a heating sleeve 3, an inner tube 4, an inner tube wall temperature sensor 5, a sample temperature sensor 6, an inner tube upper cover 7, an air Sleeve 8, cold trap upper cover 9, cold bath temperature sensor 10, semiconductor refrigerator 11, cold trap 12, magnetic stirrer 13, computer 14, electromagnetic switch 15 are connected to form.

[0034]The lower end of the cold trap 12 is fixedly installed with a magnetic stirrer 13 with a threaded fastening connector, and the magnetic stirrer 13 is connected with the electromagnetic switch 15 by a wire. The coolant in the cold trap 12 is stirred, and the outer wall of the cold trap 12 is bonded with a semiconductor refrigerator 11, and the semiconductor refrigerator 11 is connected with the electromagnetic switch 15 by a wire, and the semiconductor refrigerat...

Embodiment 2

[0051] The freezing point of the naphthalene solution was measured using the freezing point measuring instrument of Example 1, and the molecular weight of naphthalene was calculated.

[0052] In the measurement preparation process step 1 of embodiment 1, get solvent cyclohexane 24.0698g and join in the inner pipe 4, the cyclohexane liquid level is positioned at lower heating resistance wire 1 upper end ± 5mm, water is cooling liquid, and the consumption of water is 1.6L. In step 2 of the rough measurement of the freezing point of cyclohexane, the semiconductor refrigerator 11 controls the temperature of the cooling bath to be -3.5°C, which is 10°C lower than the theoretical freezing point of cyclohexane, and the lowest point of the temperature-time curve for the cooling of cyclohexane It is 6.42°C, and 6.46°C is determined to be the start-up temperature of heat dissipation compensation, which is 0.04°C higher than the temperature at the lowest point of the curve. The roughly ...

Embodiment 3

[0057] The freezing point of the naphthalene solution was measured using the freezing point measuring instrument of Example 1, and the molecular weight of naphthalene was calculated.

[0058] In the freezing point process step 4 of the mensuration naphthalene-cyclohexane solution of embodiment 2, naphthalene 0.7469g in the naphthalene-cyclohexane solution, the molar fraction of naphthalene in the naphthalene-cyclohexane solution is 0.02, other in this process step Step is identical with embodiment 2. Other steps are identical with embodiment 2. The freezing point of cyclohexane and the freezing point of naphthalene-cyclohexane solution are shown in Table 3.

[0059] Table 3 Example 3 cyclohexane freezing point and naphthalene-cyclohexane solution freezing point measured value

[0060]

[0061] In calculating the molecular weight process step 5 of naphthalene, the molecular weight calculated by formula (2) and formula (3) is 131.04, and the relative error with the theoreti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com