A control method for an optical drive with different bandwidths

A driver, optical technology, used in optical recording/reproduction, instrument, head configuration/installation, etc., can solve problems such as tracking loss, not fast enough, and sub-optimal performance, achieve bandwidth optimization, and reduce power consumption , fast and efficient minimization or attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

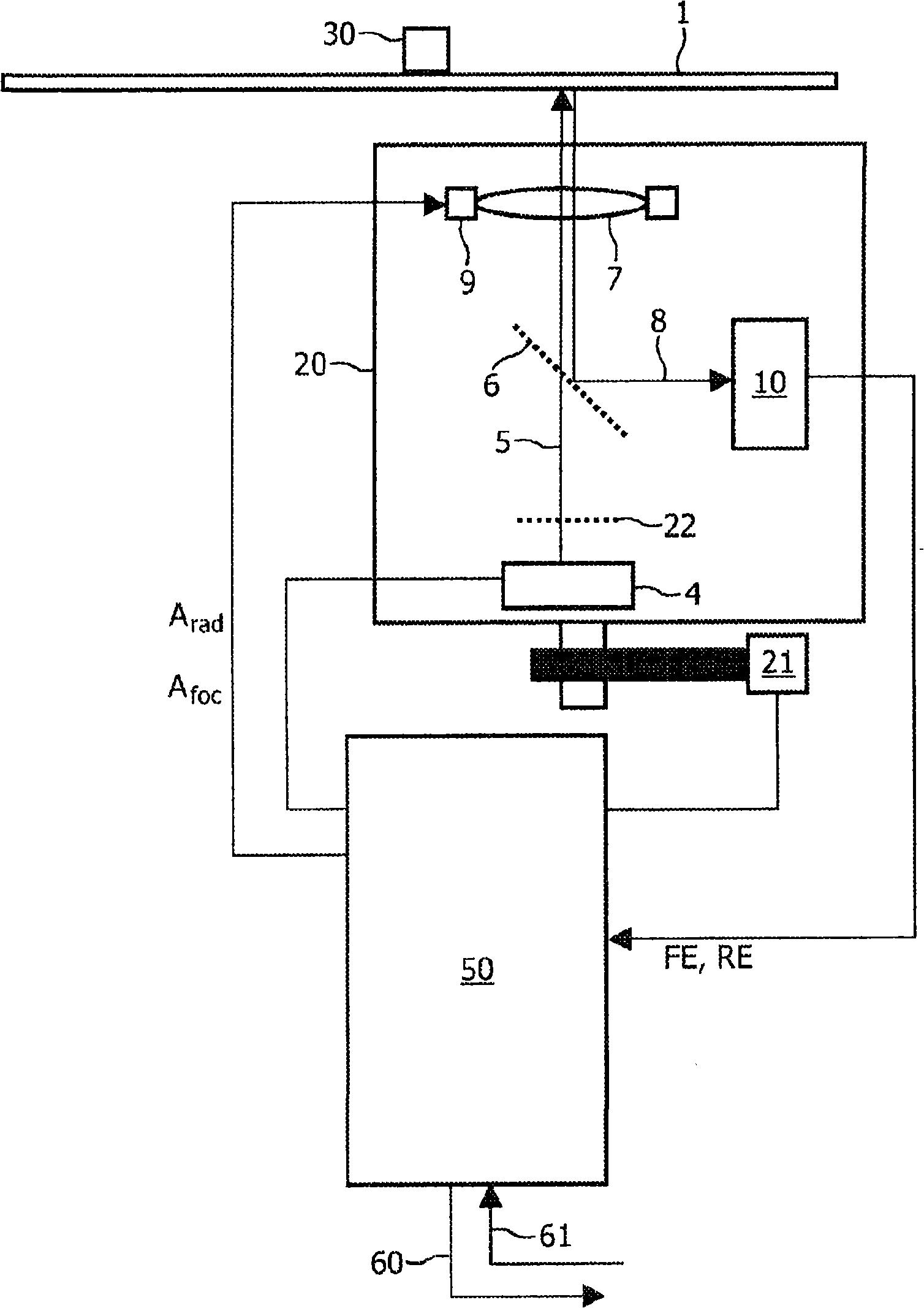

[0047] figure 1 is a schematic block diagram of one embodiment of an optical drive / optical device according to the present invention. The optical carrier 1 is fixed and rotated by a clamping device 30 .

[0048] In one embodiment, the carrier 1 comprises a material suitable for recording information by means of a radiation beam 5 . The recording material may be eg magneto-optical type, phase change type, dye type, metal alloy like copper / silicon or any other suitable material. Information can be recorded on the carrier 1 in the form of optically detectable areas, also called marks for rewritable (RW) media, for writable or write-once-read-many media ( WORM) is called pits.

[0049] In another embodiment, the carrier 1 is of the read-only type, wherein information or data is read from the carrier 1 but it is not possible to record data on the carrier 1 . A carrier 1 of this type may have a read only memory (ROM) format.

[0050] The optical drive / optical device comprises a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com