Vibrating turning mixed flow type complete-alternation granule wax shale destructive distillation method and device

A technology of oil shale and dry distillation, which is applied in the field of vibratory reentry mixed-flow full-circulation small particle oil shale dry distillation and equipment, which can solve the problems of unbuilt industrial experimental equipment and achieve a simple structure, high oil yield and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

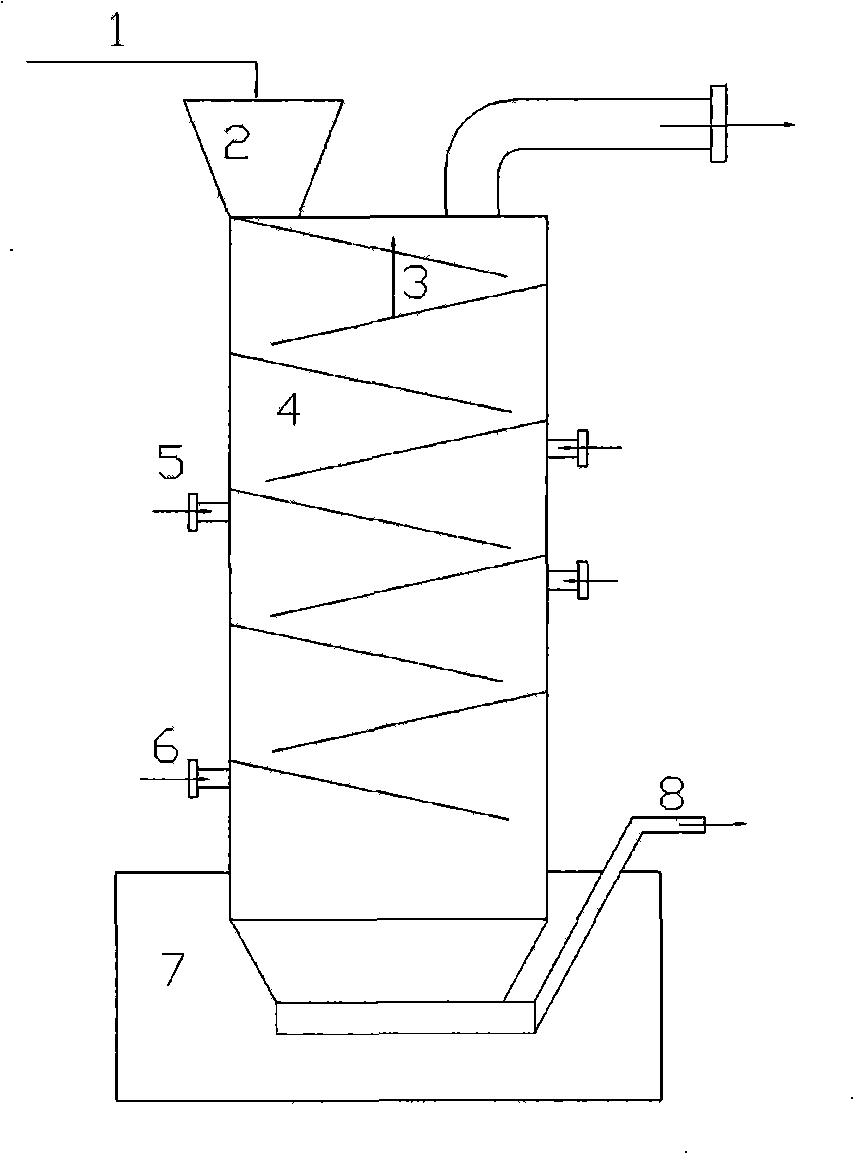

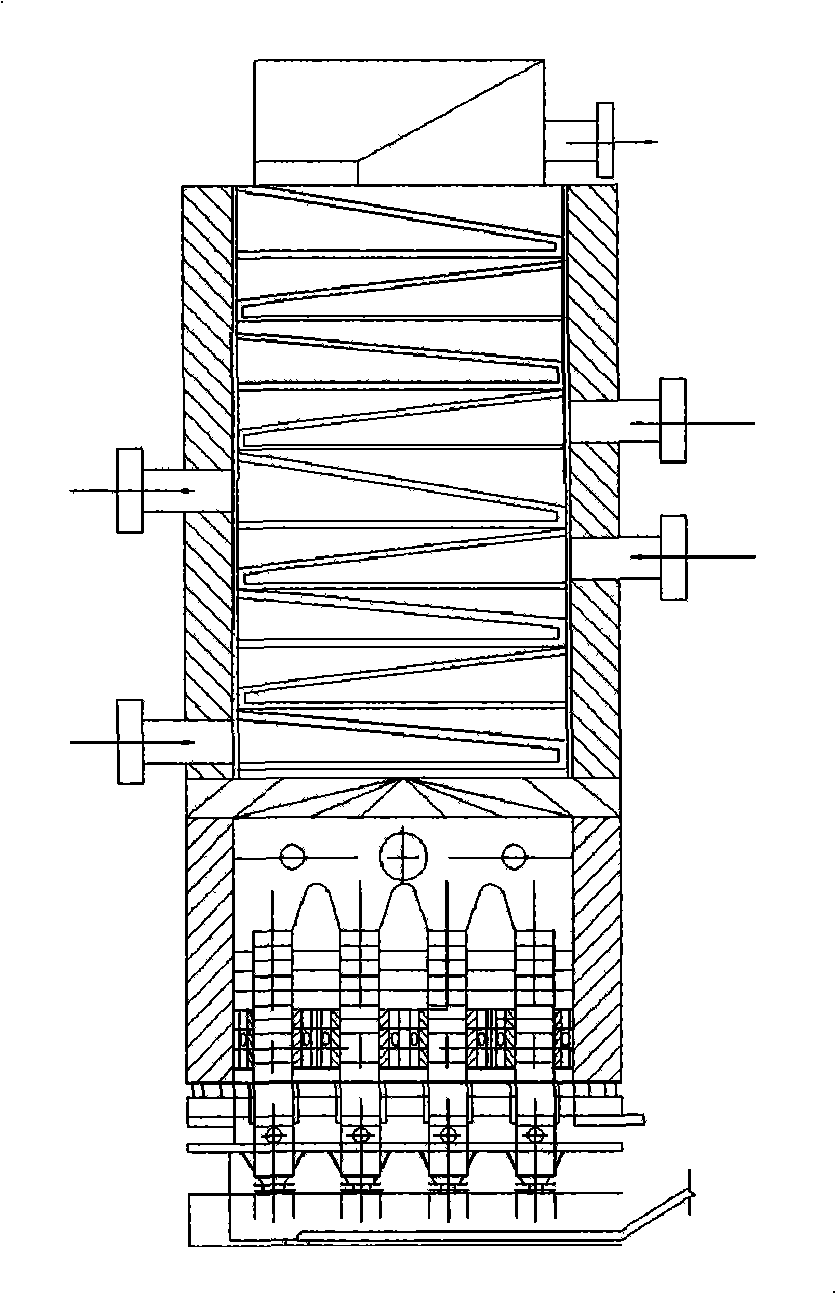

[0014] Accompanying drawing 2 is the specific implementation device of this new process. The retort furnace is equipped with nine layers of reentrant vibrating beds, and the thermal cycle gas at 700°C enters from the lower part of the three-layer vibrating beds of 4, 5, and 6, so that the oil shale and gas gas in the retort furnace have a mixed flow. The height of the retort section is 4.5m-5m. The cold cycle gas enters from the lower part of the ninth vibrating bed, and cools the dry-distilled semi-coke to 250°C in a mixed flow state. The semi-coke falls into a closed water pool and is cooled to 80°C before being discharged out of the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com