Steel sphere surface peening technique

A surface strengthening and surface strengthening machine technology, applied in the field of steel ball surface strengthening technology, can solve the problems of uneven surface grinding, difficult precision, uneven surface hardness of steel balls, etc., to improve processing quality, improve surface quality, improve The effect of bearing dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

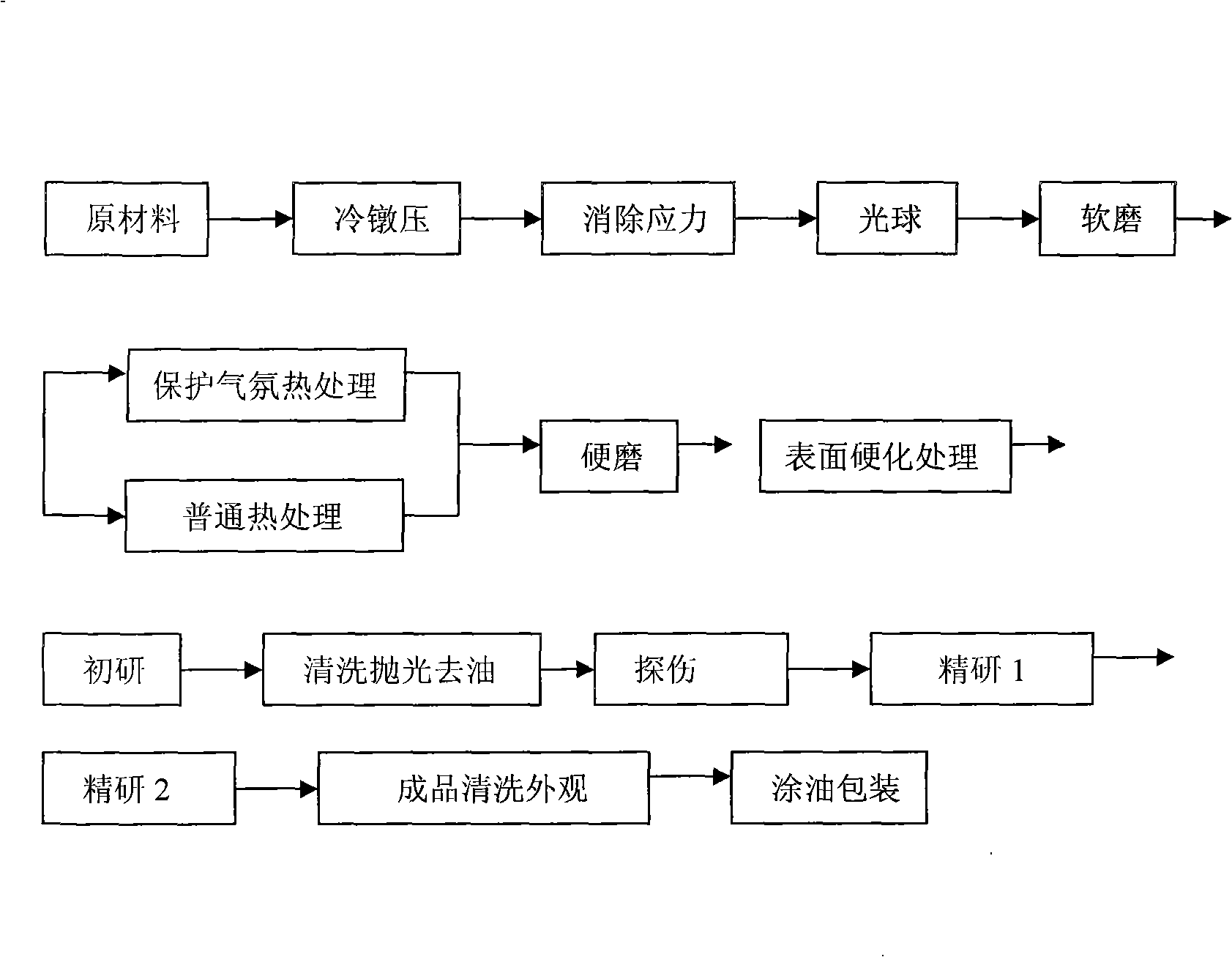

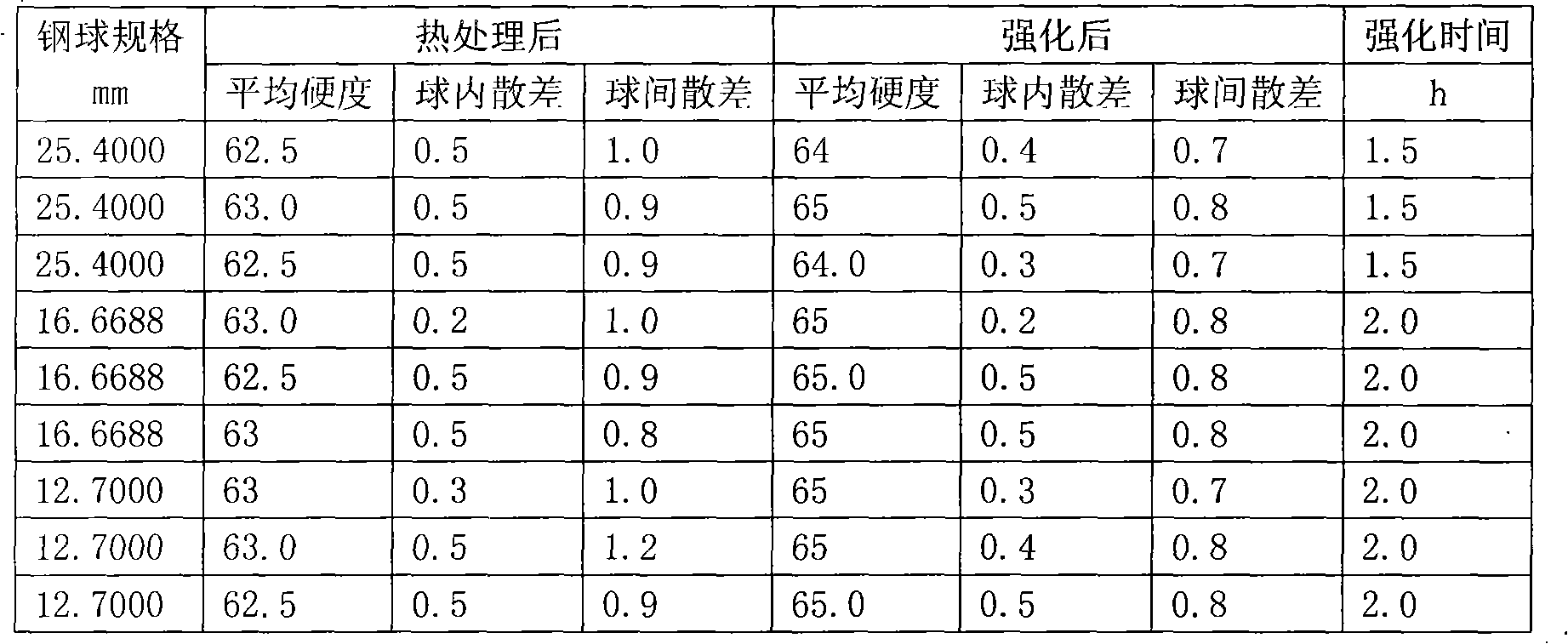

[0017] Such as figure 1 As shown, the whole process of steel ball production is: selection of raw materials, light drawing, cold pier pressure, stress relief, light ball, soft grinding, heat treatment, hard grinding, surface strengthening, preliminary research, cleaning and polishing to remove oil, flaw detection, and fine grinding. Second, the appearance of the finished product is cleaned, oiled and packaged. Except for the surface strengthening process in the above steps, other processes are commonly used processes, so the description will not be repeated here.

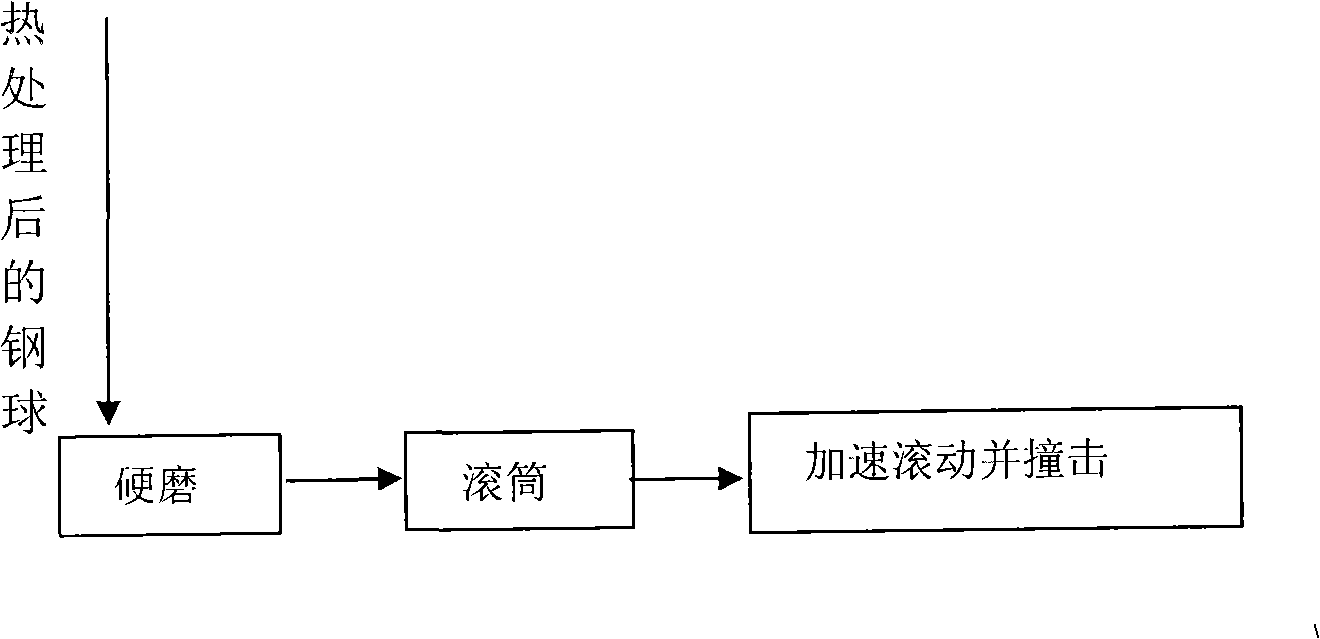

[0018] Such as figure 2 As shown, the specific process of the above-mentioned surface strengthening process is as follows: first, a. Hard grinding the steel ball after heat treatment; b. Flowing the hard ground steel ball into the roller of the steel ball surface strengthening press through the guide groove; c. Accelerate the rolling of the roller of the steel ball surface strengthening press machine, and the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com