Automatic calibration type distributed optical fiber temperature measurement sensing equipment and its use method

A technology of distributed optical fiber and sensing devices, which is applied in the direction of measuring devices, thermometer testing/calibration, thermometers, etc., can solve problems such as large manpower and material resources, interrupting temperature detection, and affecting the accuracy of temperature measuring devices, so as to save material and financial resources, Effect of reducing downtime and frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

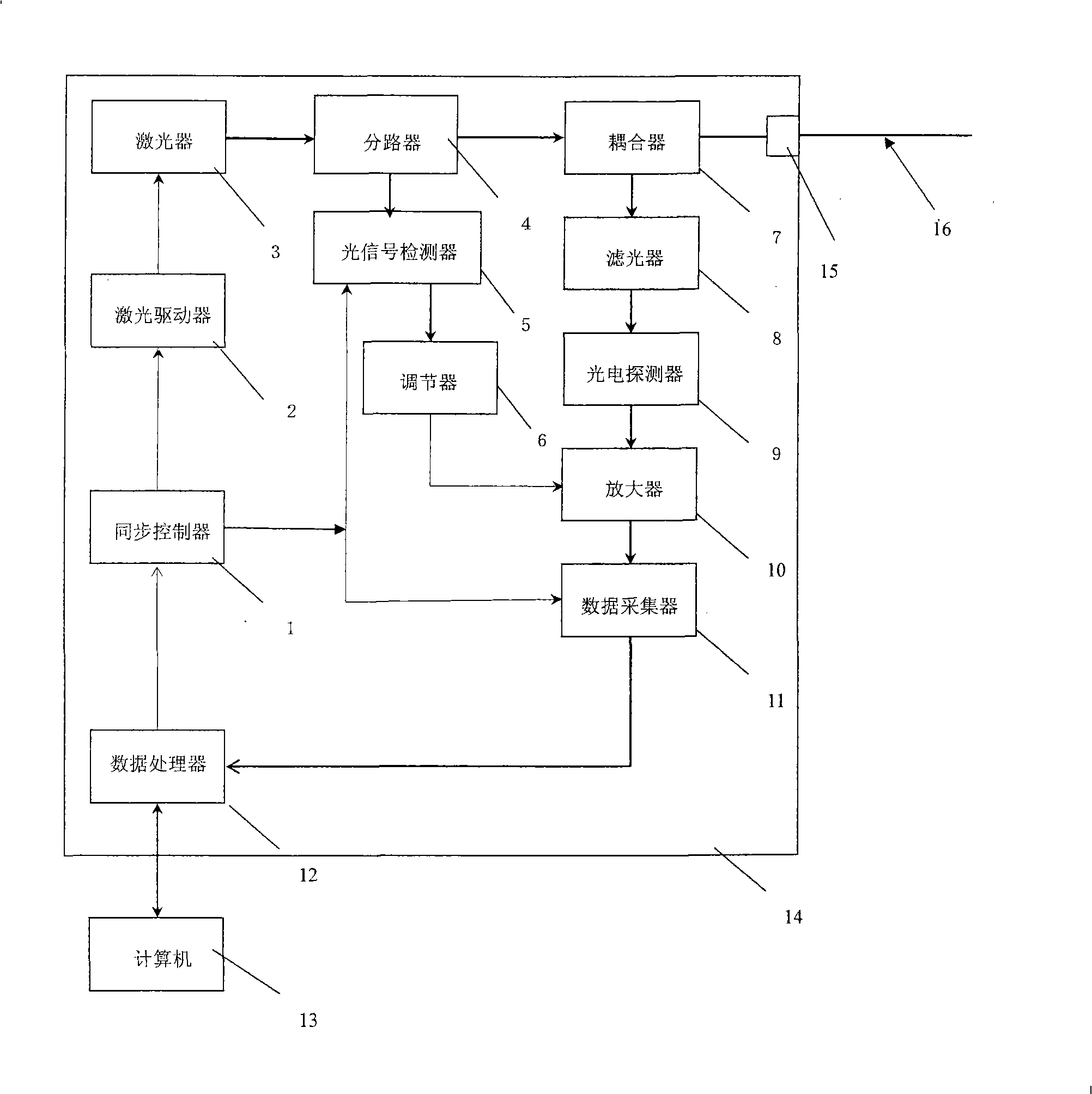

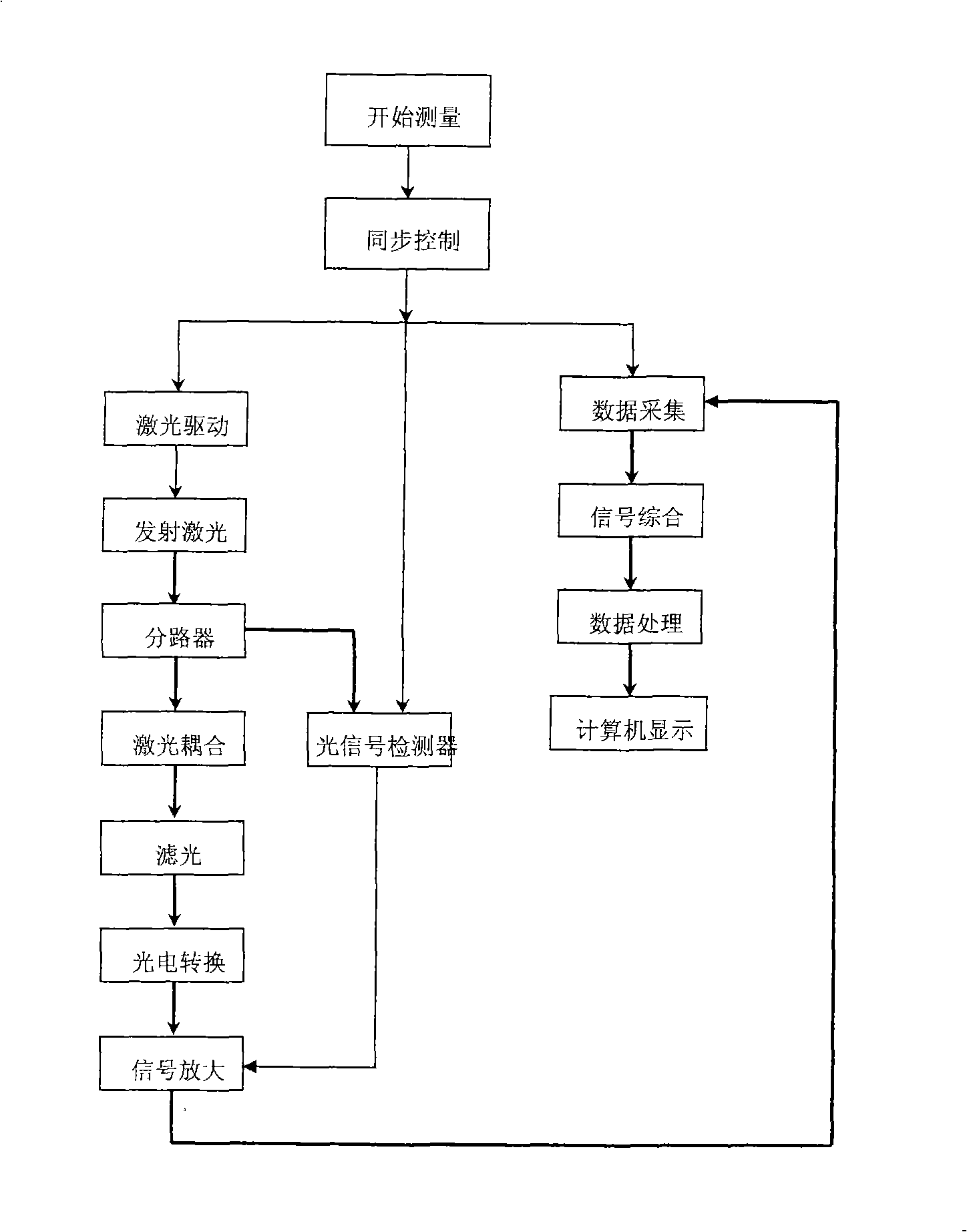

[0016] Below with reference to accompanying drawing, the present invention is further described:

[0017] The present invention is an automatic calibration type distributed optical fiber temperature sensing device and its use method, which mainly includes a device housing 14, a laser 3 is arranged in the device housing 14, and the input end of the laser device 3 is connected to the output end of the laser driver 2 , the input end of laser driver 2 is connected with the output end of synchronous controller 1, the output end of coupler 7 is connected with the input end of optical filter 8, the output end of optical filter 8 is connected with the input end of photodetector 9, The output end of photodetector 9 is connected with the input end of signal amplifier 10, and the output end of signal amplifier 10 is connected with the input end of data collector 11, and coupler 7 places are provided with optical fiber interface 15, and its difference from prior art is: The output end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com