Monomer voltage polling module of super capacitor bank

A supercapacitor and monomer voltage technology, applied in the direction of using digital measurement technology for measurement, etc., can solve the problems of long switching time, difficult to guarantee accuracy, and cumbersome problems, and achieve the effects of increased service life, convenient connection, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

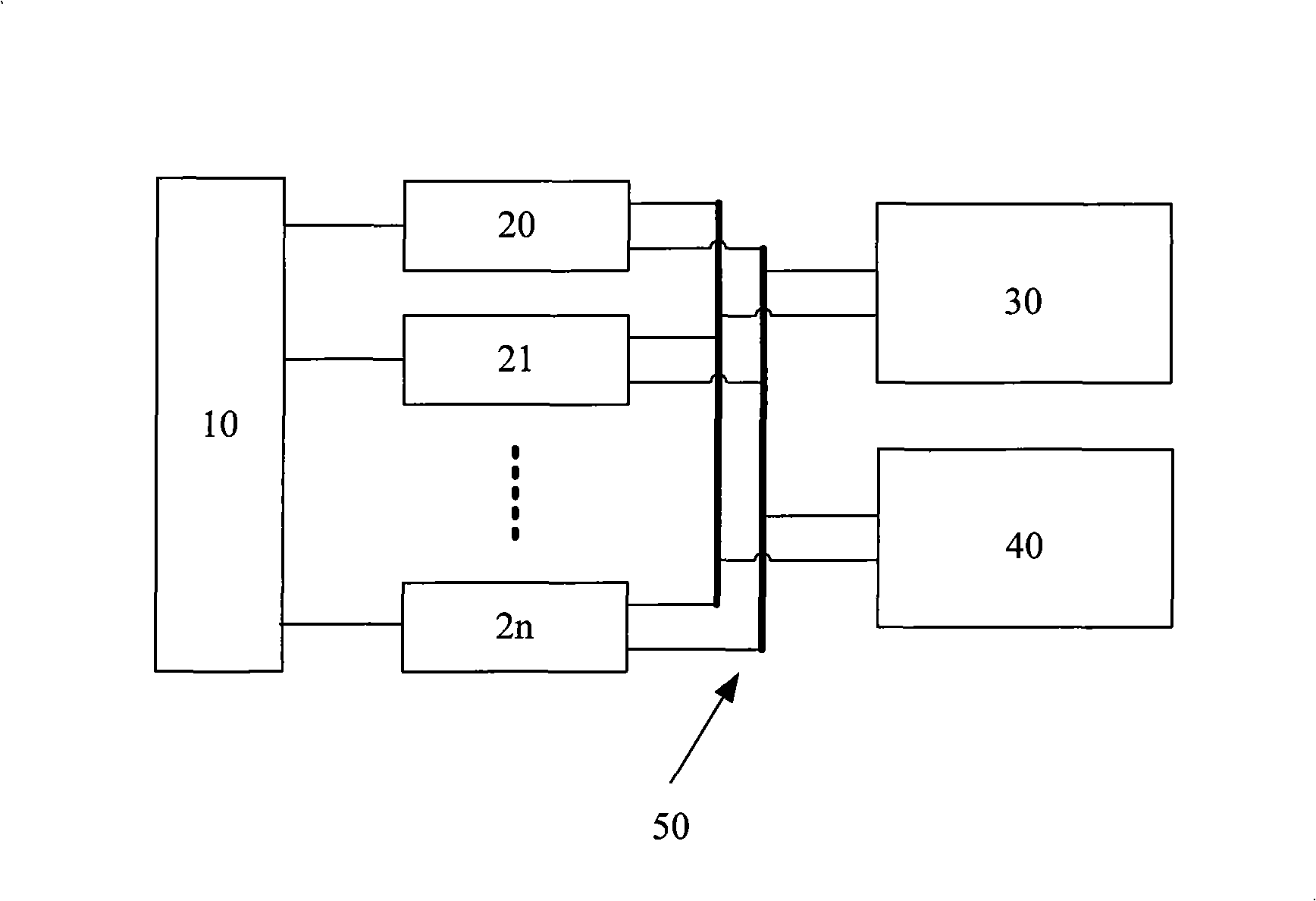

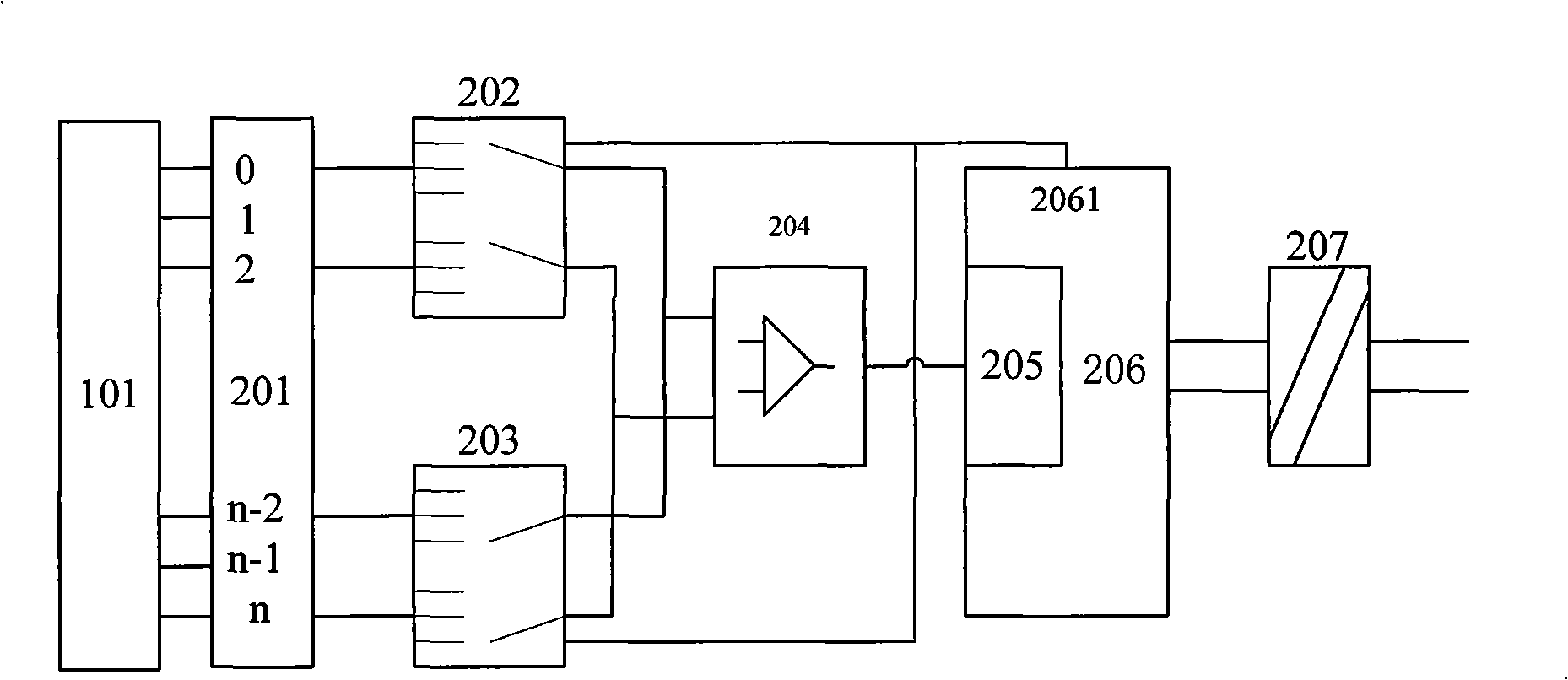

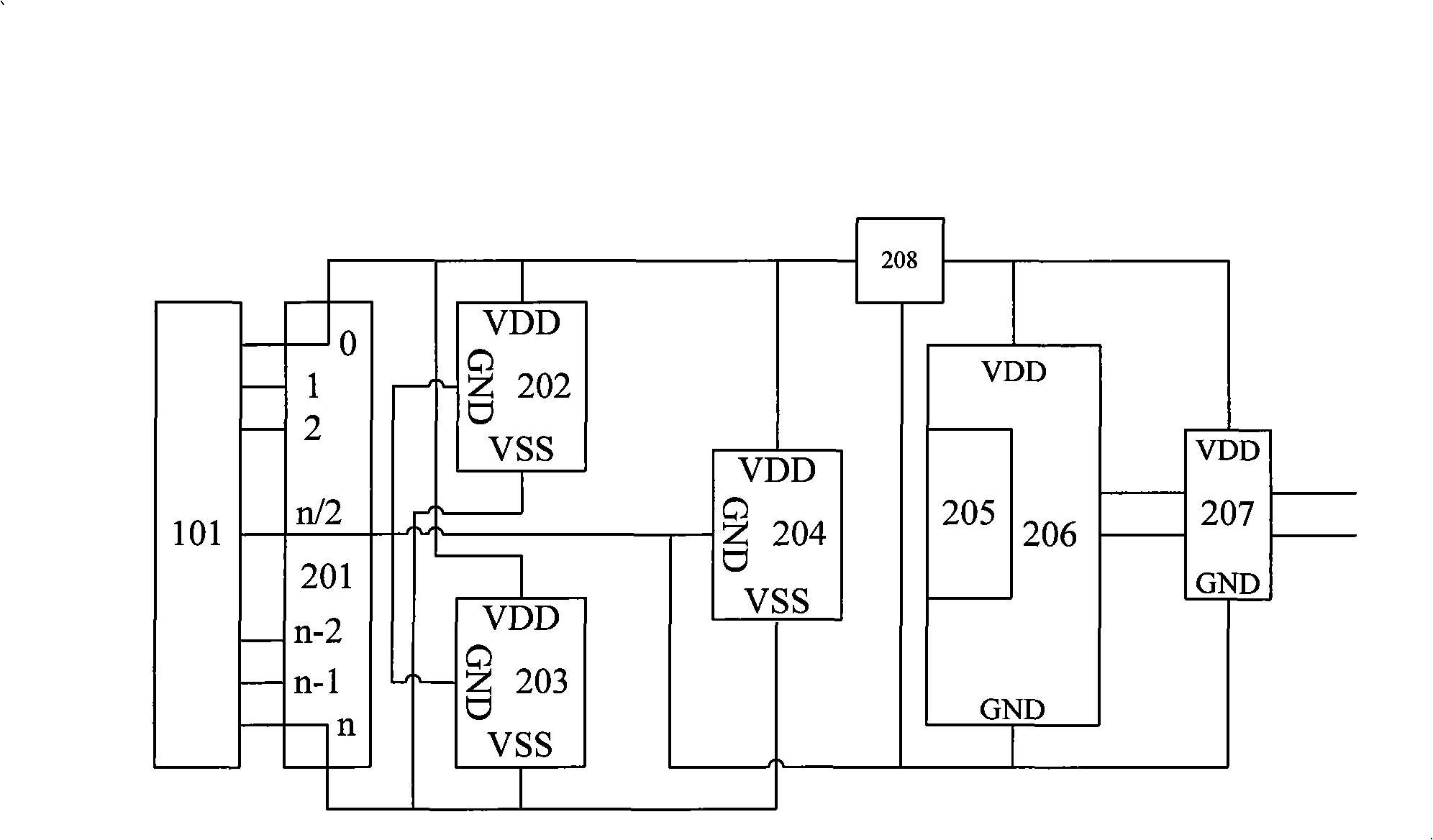

[0026] The supercapacitor bank monomer voltage inspection module is characterized in that it includes terminals for connecting the supercapacitor bank, a plurality of analog switches powered by the supercapacitor bank, operational amplifiers, A / D converters, single-chip microcomputers, and bus communication module, the independent input / output terminals of the plurality of analog switches are connected to the terminals, the common input / output terminals of the plurality of analog switches are connected to the input terminals of the operational amplifier, and the output terminals of the operational amplifier are connected to the A / The input end of the D converter is connected, the output end of the A / D converter is connected with the bus communication module through a single-chip microcomputer, and the digital I / O port of the single-chip microcomputer is connected with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com