Indoor coating having humidity conditioning function and construction method thereof

A technology for interior wall coatings and functional materials, which is applied in the field of building decoration materials, can solve the problems of small moisture release of organic humidity-controlling materials, space pollution of objects, and small moisture capacity of montmorillonite, so as to achieve good indoor environment humidity adjustment and excellent The effect of using the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] Acrylic emulsion 100g

[0045] Attapulgite (after pretreatment) 200 grams

[0046] Diatomaceous earth (after pretreatment) 100 grams

[0047] Light Calcium 100g

[0049] DISPERBYK-108 15g

[0050] Alcohol Ester-12 10g

[0051] BYK-052 15g

[0052] Ammonia 10g

[0053] 350 grams of water

[0054] Prepare the humidity-adjusting paint of this example by the paint preparation method.

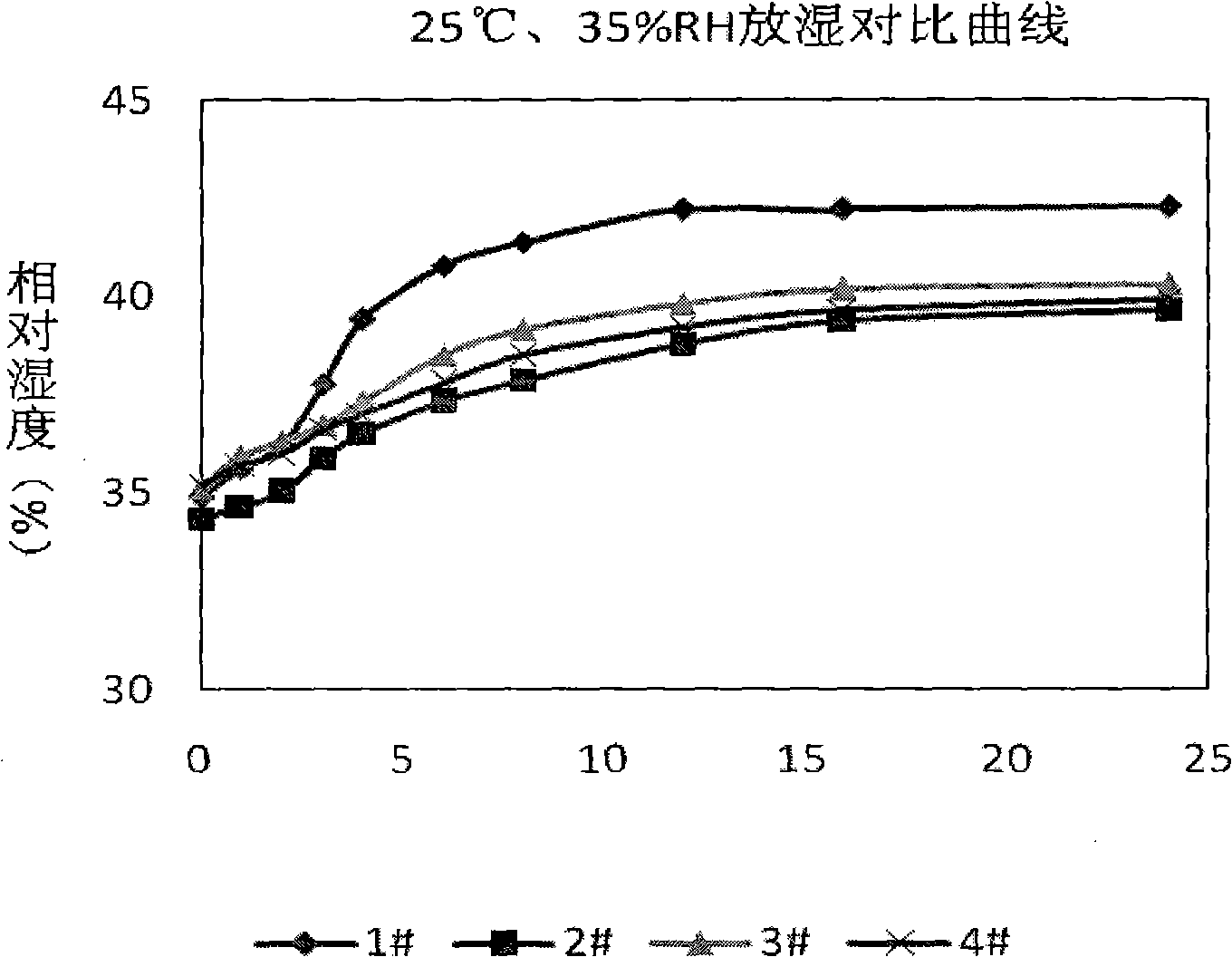

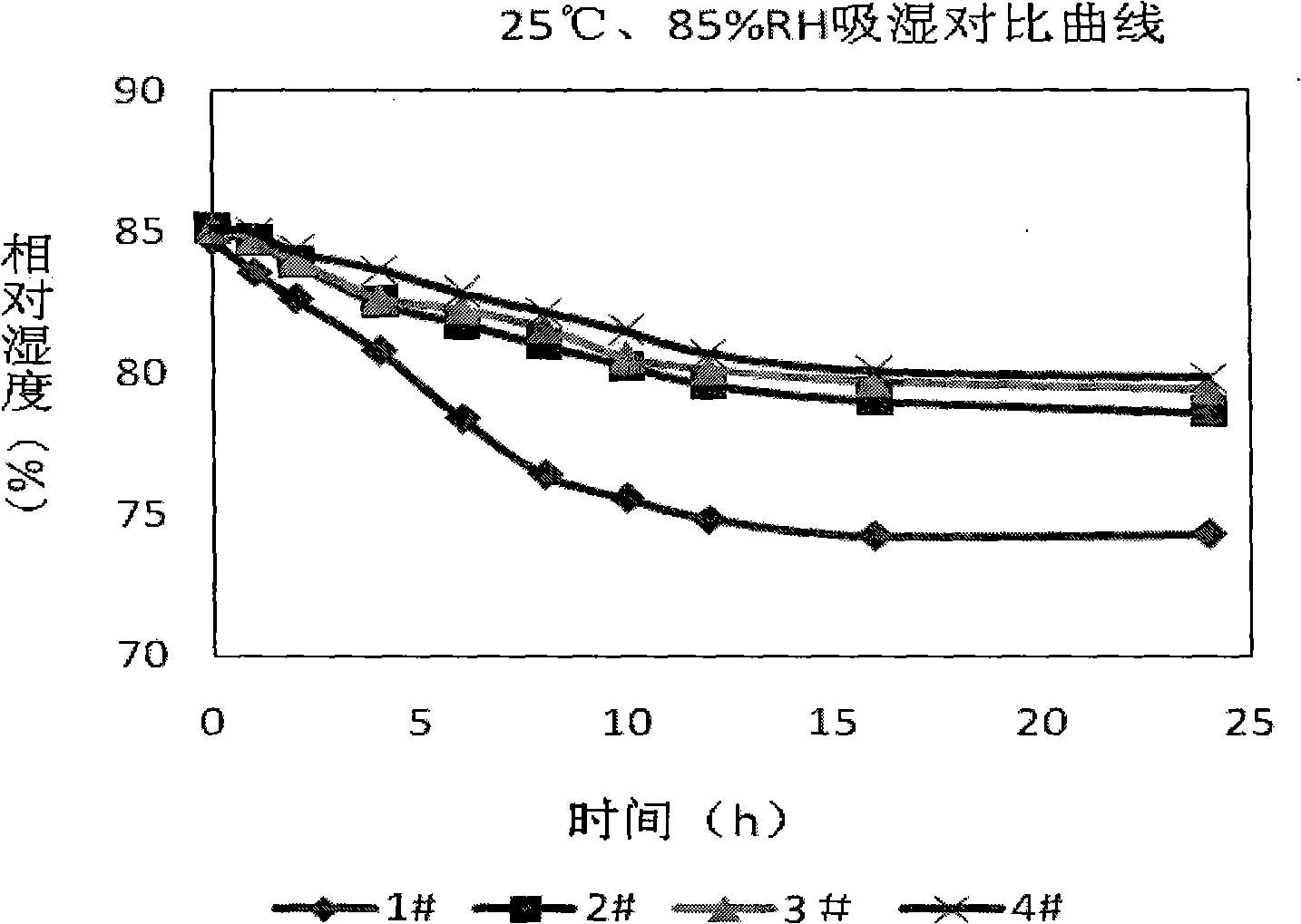

[0055] Test method and results: The paint was sprayed on two glass plates of 150mm×150mm according to the construction process of the present invention, and after natural drying, it was placed in an oven and dried at 80°C for 5 hours. Place two samples in a 10L airtight container with a temperature of 25°C and a relative humidity of 85%, and measure the maximum decrease in relative humidity in the container. After the relative humidity in the airtight container reaches equilibrium, change the environmental conditions in the container to 25°C and 35% relative...

example 2

[0061] styrene acrylic emulsion 400g

[0062] Sepiolite (after pretreatment) 210 grams

[0064] Lithopone 80g

[0065] Wollastonite powder 60g

[0066] Acrylic emulsion T-117A 5g

[0067] KATHON LXE 5g

[0068] Hydrochloric acid 10 grams

[0069] 150g water

[0070] Carry out functional test with the same method as Example 1, as a result, under the conditions of temperature 25°C and relative humidity 85%, the maximum reduction of relative humidity reaches 8%RH; Dehumidification under certain conditions, resulting in a maximum increase in relative humidity of 6% RH.

example 3

[0072] Vinegar Acrylic Emulsion 200g

[0073] Zeolite powder (after pretreatment) 150 grams

[0074] Kaolin (after pretreatment) 150g

[0075] Attapulgite clay 150g

[0076] Talc powder 100g

[0077] DISPERBYK-108 5 g

[0078] BYK-052 5g

[0079] water 240g

[0080] Carry out functional test with the same method as Example 1, the result is under the condition of temperature 25 ℃, relative humidity 85%, relative humidity maximum reduction amount reaches 10%RH; Dehumidification under certain conditions, resulting in a maximum increase in relative humidity of 6% RH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com