Method for measuring impurity in high pure gold by plasma atomic emission spectrometer

An atomic emission and plasma technology, which is used in the preparation of test samples, electrical excitation analysis, material excitation analysis, etc., can solve the problems of large gold standard and sample loss, affecting the authenticity of measurement data, and large influence of alloy composition. , to achieve the effect of small matrix loss, fast measurement speed and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

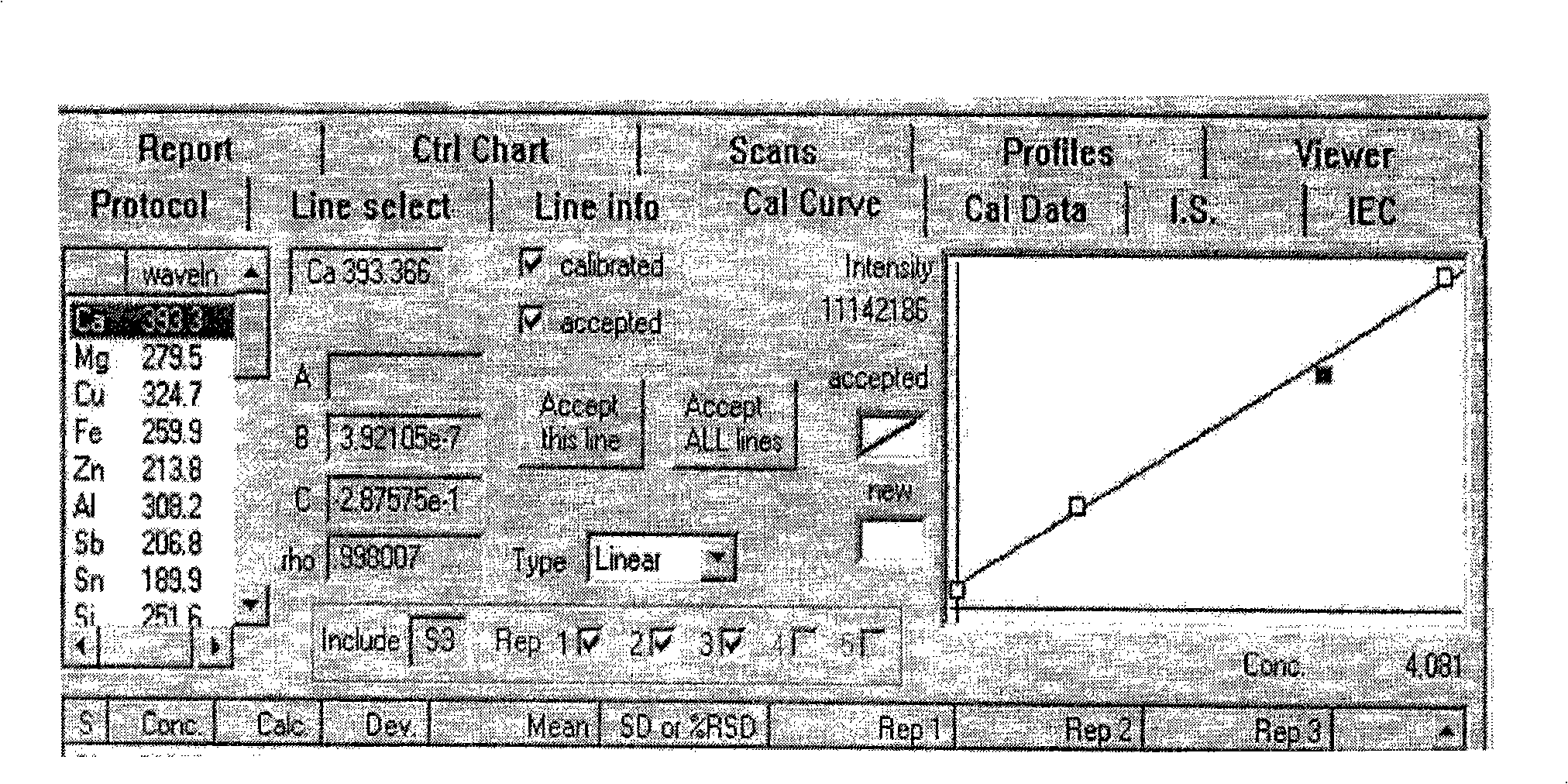

Image

Examples

Embodiment 1

[0063] Impurity detection for a high-purity gold wire:

[0064] The specific determination method steps are as follows:

[0065] 1. Clean the sample

[0066] Weigh about 2 g of high-purity gold wire, boil the sample with (1+1) hydrochloric acid for 15 minutes, rinse it with deionized water, and dry it in a plexiglass glove box with an infrared lamp.

[0067] 2. Sample dissolution

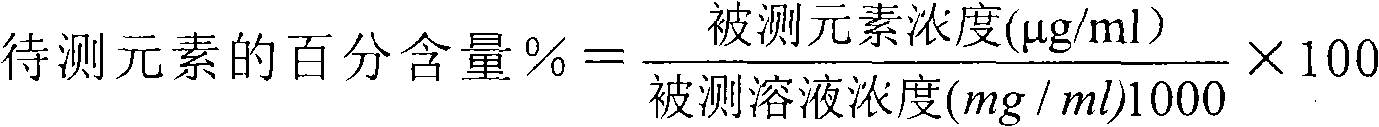

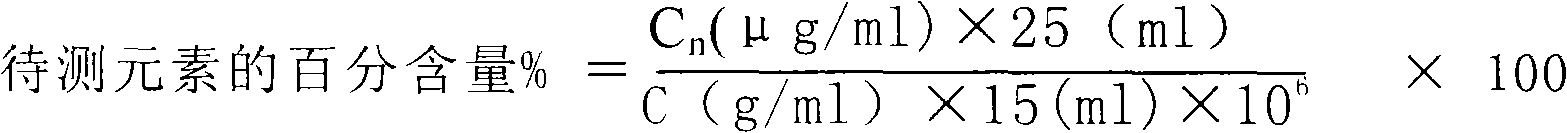

[0068] Weigh 1.000 g of the above-mentioned cleaned high-purity gold wire sample into a 100 ml quartz beaker, add 15 ml of aqua regia, cover with a watch glass, place it on an electric heating plate and heat at low temperature (about 60-80°C) to dissolve. After the sample is completely dissolved, transfer it to a 100ml volumetric flask when it is cooled to room temperature, add 5ml of hydrochloric acid, and dilute to the mark with deionized water. The concentration of the solution is C (C=0.01g / ml).

[0069] 3. Sample separation and standard addition

[0070] Separate the sample solution into fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com