Method for improving etching depth accuracy

A technology of etching depth and accuracy, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as inaccurate exposure rates, improve production efficiency, avoid scrap, and save manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

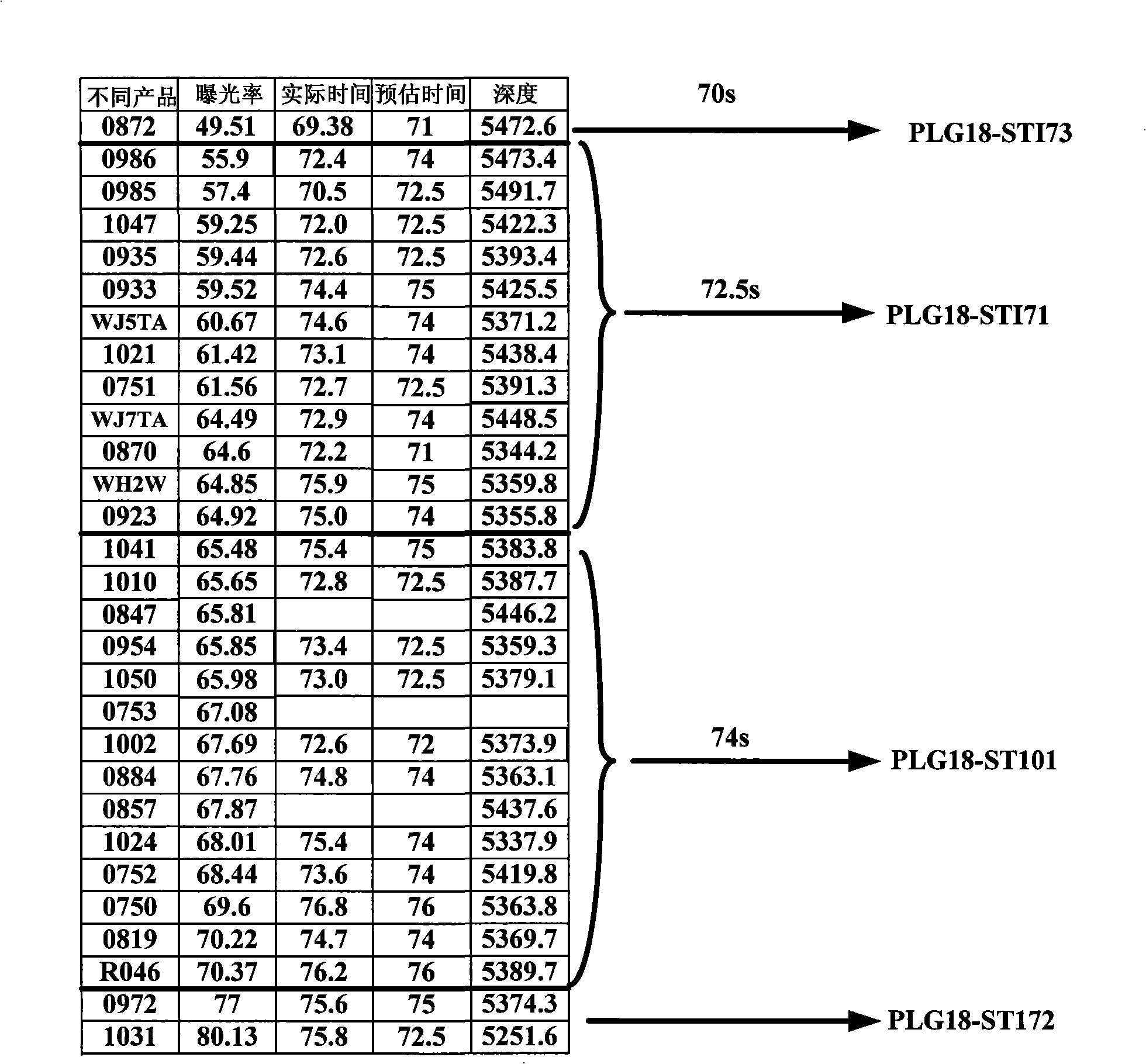

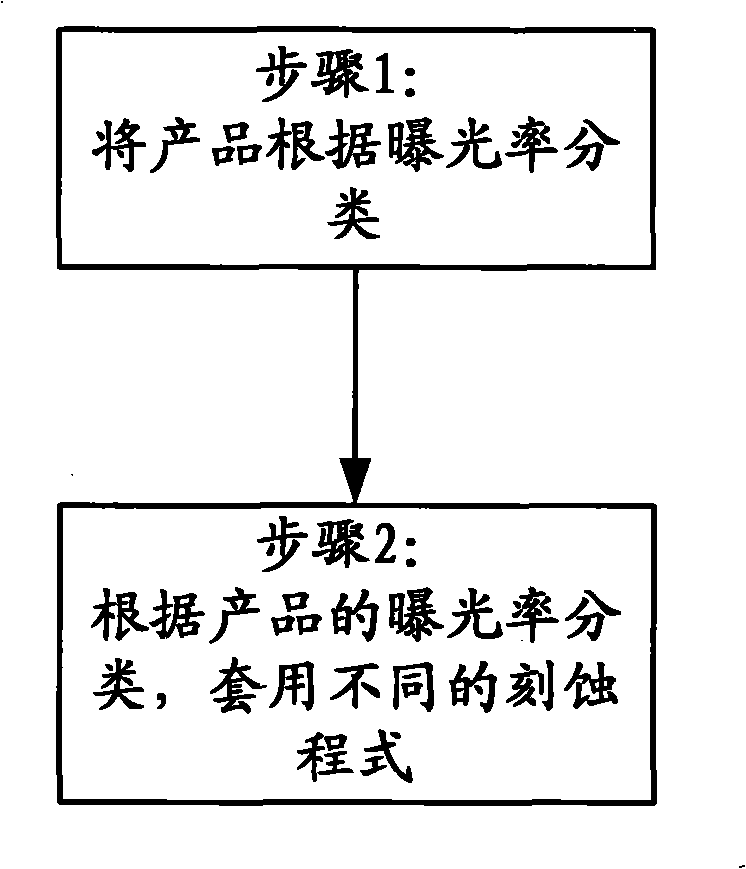

[0015] figure 1 It is a schematic diagram of the program determination of the present invention. The first row of the table represents different products; the second row of the table represents the exposure rate; the third row of the table represents the actual time, that is, the actual etching time required based on experience; the fourth row of the table represents The estimated time is the previously estimated etching time before etching; the fifth column indicates the depth, that is, the etching depth, and the actual time can be obtained according to the mentioned depth. Such as figure 1 As shown, there is a large discrepancy between past estimated times and actual times. In the present invention, different programs are applied to samples from the actual etched products, and the time of the programs is the average value of the actual ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com