Reaction and solid-liquid separation integrated device

A solid-liquid separation and reaction technology, applied in the direction of filtration separation, separation method, mixer with rotating stirring device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

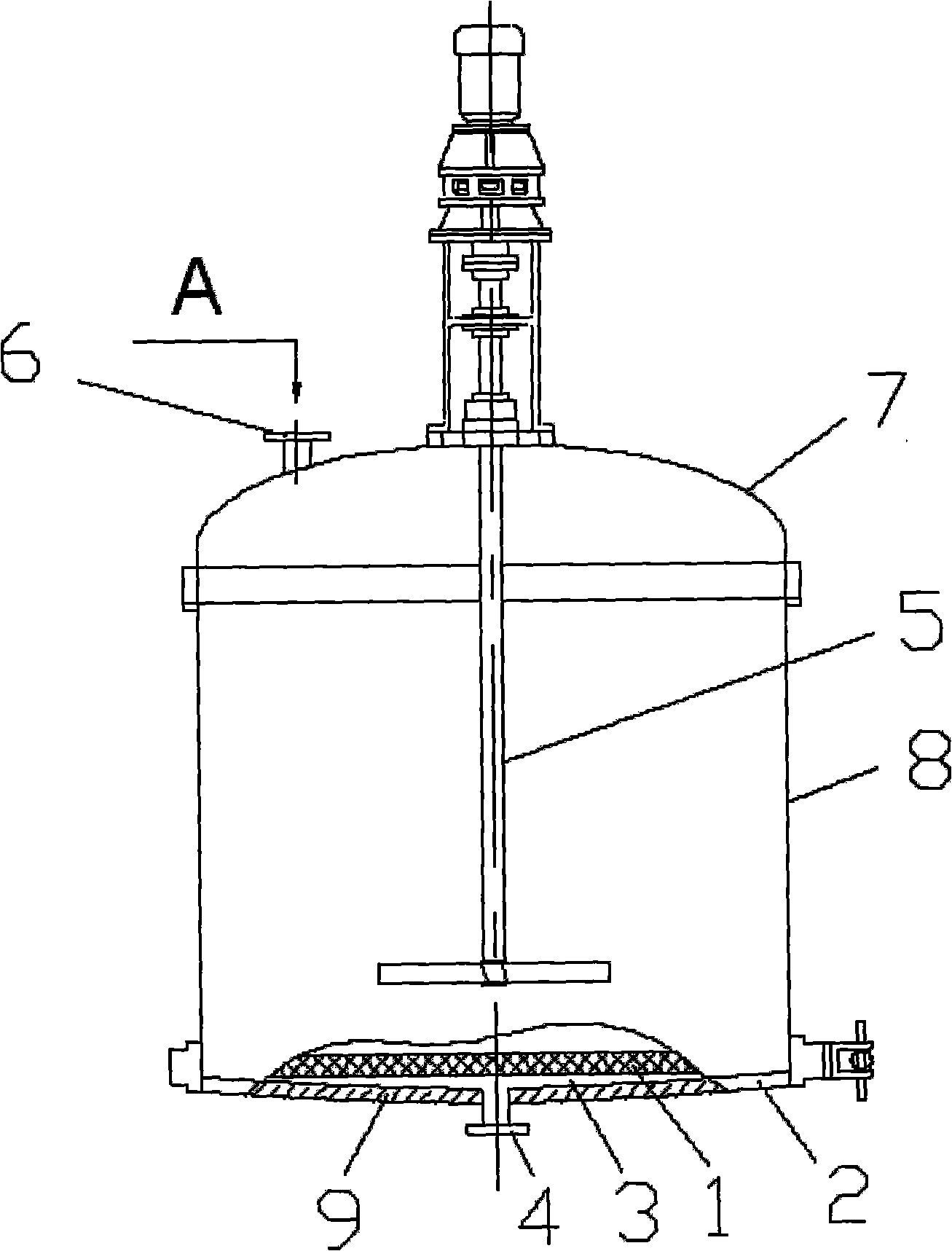

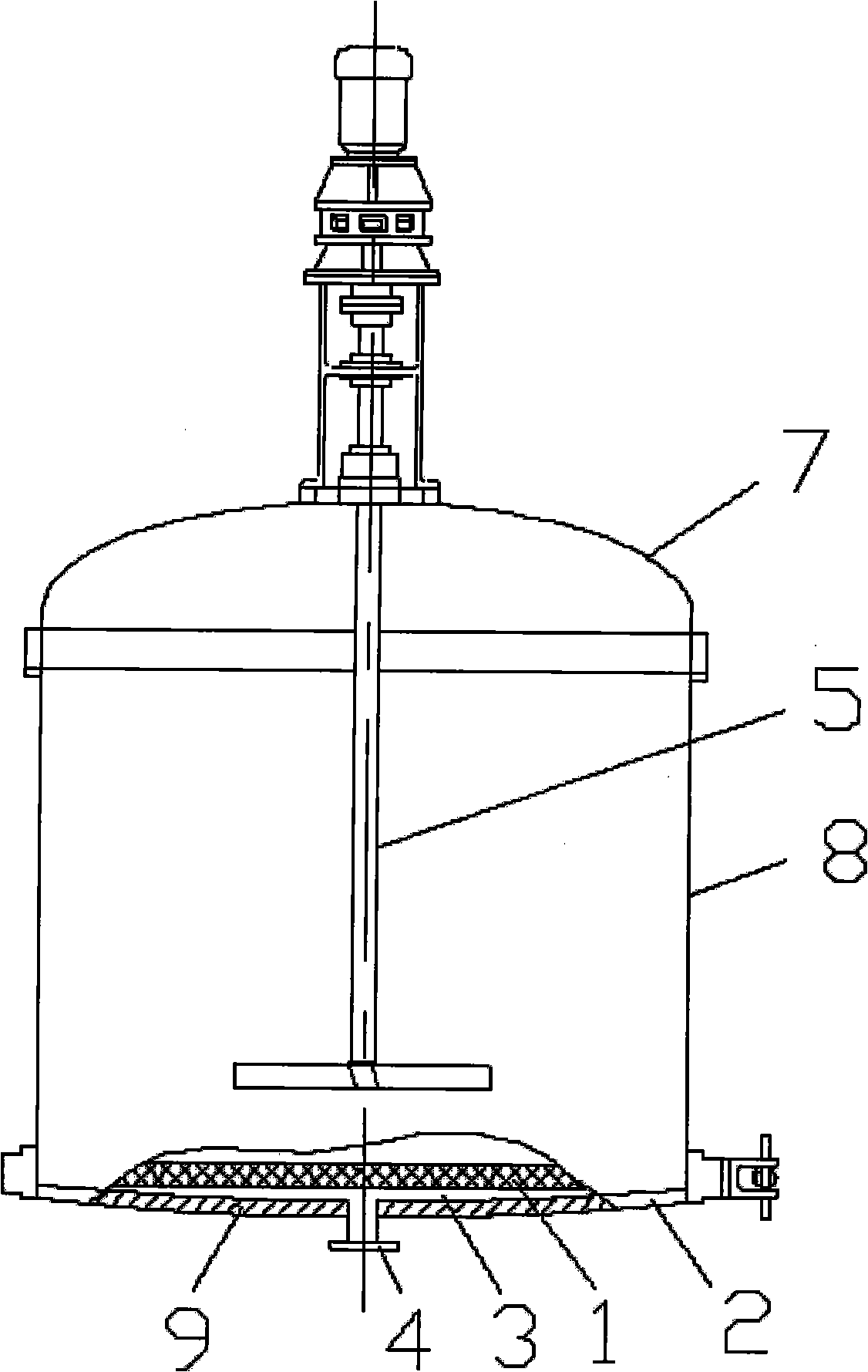

[0033] The device of this embodiment comprises a loam cake 7, a bottom 2, and a cylinder body 8. The stirring paddle 5 is fixed on the center of the loam cake 7 by a shaft seal structure, and the agitation paddle is in the cylinder body; the bottom 2 includes a concave shell 9 , microporous filter plate 1, liquid outlet 4, the top of the concave shell is covered with a microporous filter plate 1 made of hydrophobic material, and the bottom of the concave shell is provided with a liquid outlet 4; the upper cover 7 is provided with the air inlet 6 that connects air compressor.

[0034] A vacuum pipeline or an air pressure pipeline is connected to the liquid outlet 4 to restore the hydrophobic performance of the microporous filter plate 1 . During use or after a period of time, if the hydrophobicity of the microporous filter plate is reduced due to the contamination of the treatment solution, the air compressor can be turned on to pass through the liquid outlet, and the hydrophob...

Embodiment 2

[0038] The device of the present embodiment comprises a loam cake 7, a bottom 2, and a cylinder body 8, and the stirring paddle 5 is fixed on the center of the loam cake 7 by a shaft seal structure, and the agitating paddle is in the cylinder body; the bottom comprises a concave shell 9, The microporous filter plate 1 and the liquid outlet 4 are covered with a microporous filter plate 1 made of hydrophobic material on the top of the concave shell, and the bottom of the concave shell is connected with a vacuum device or a pressure pipe to discharge the liquid Mouth 4.

[0039] The microporous filter plate 1 is tightly embedded in the upper end of the concave shell 9 of the device through a sealing ring.

[0040] The cylinder 8 is openably connected to the bottom 2 and can be quickly opened or closed. In the closed state, the cylinder becomes a flat-bottomed reactor. Opening the bottom is conducive to overall cleaning and cleaning.

example 1

[0042] Example 1 Add a solid tungsten sinking agent into the device of the present invention equipped with tungsten and molybdenum acidic solution, and the original composition of the solution is WO 3 3.32g / L, Mo 2.23g / L, P~15g / L, HCl 1.7mol / L, after heating to 70°C, add 3 / 1000 tungsten precipitation agent, stir slowly for 20 minutes, and then age for 240 Minutes, then pass through the compressed air to filter, then stir and wash with a small amount of water, after the compressed air is filtered, start the openable connection setting at the bottom of the cylinder of the present invention, open the bottom shell 2, and the sediment will fall into the pre-placed receiver. Analyze the filtrate composition as WO 3 0.216g / L, Mo 1.945g / L, P 14.71g / L, HCl 1.7mol / L. Precipitation component is WO 3 48.75%, Mo 5.72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com