Preparation of polyimide glass fiber composite material

A polyimide glass fiber composite material and glass fiber technology, which is applied in the field of polyimide glass fiber composite material preparation, can solve the problems of poor bonding of glass fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

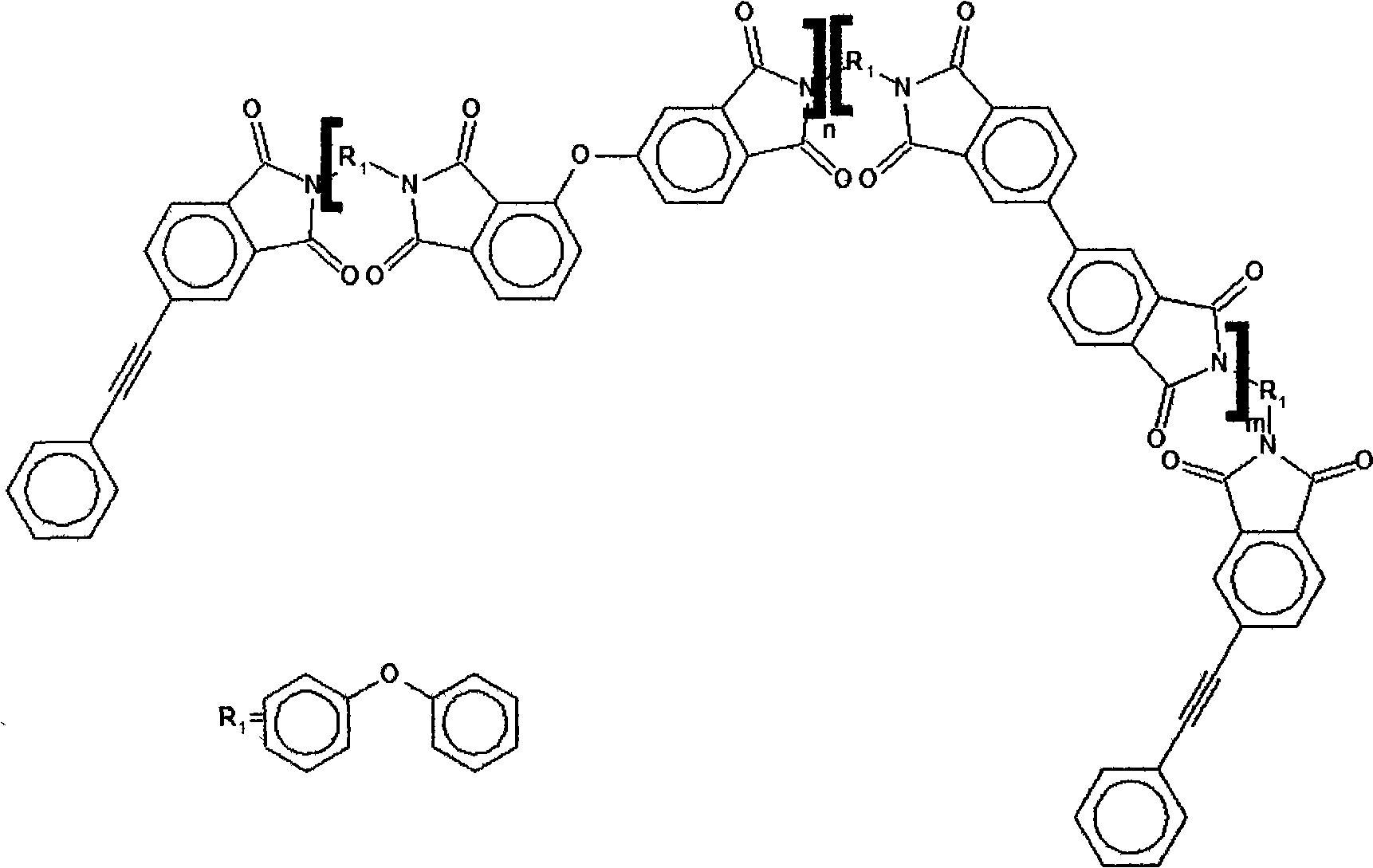

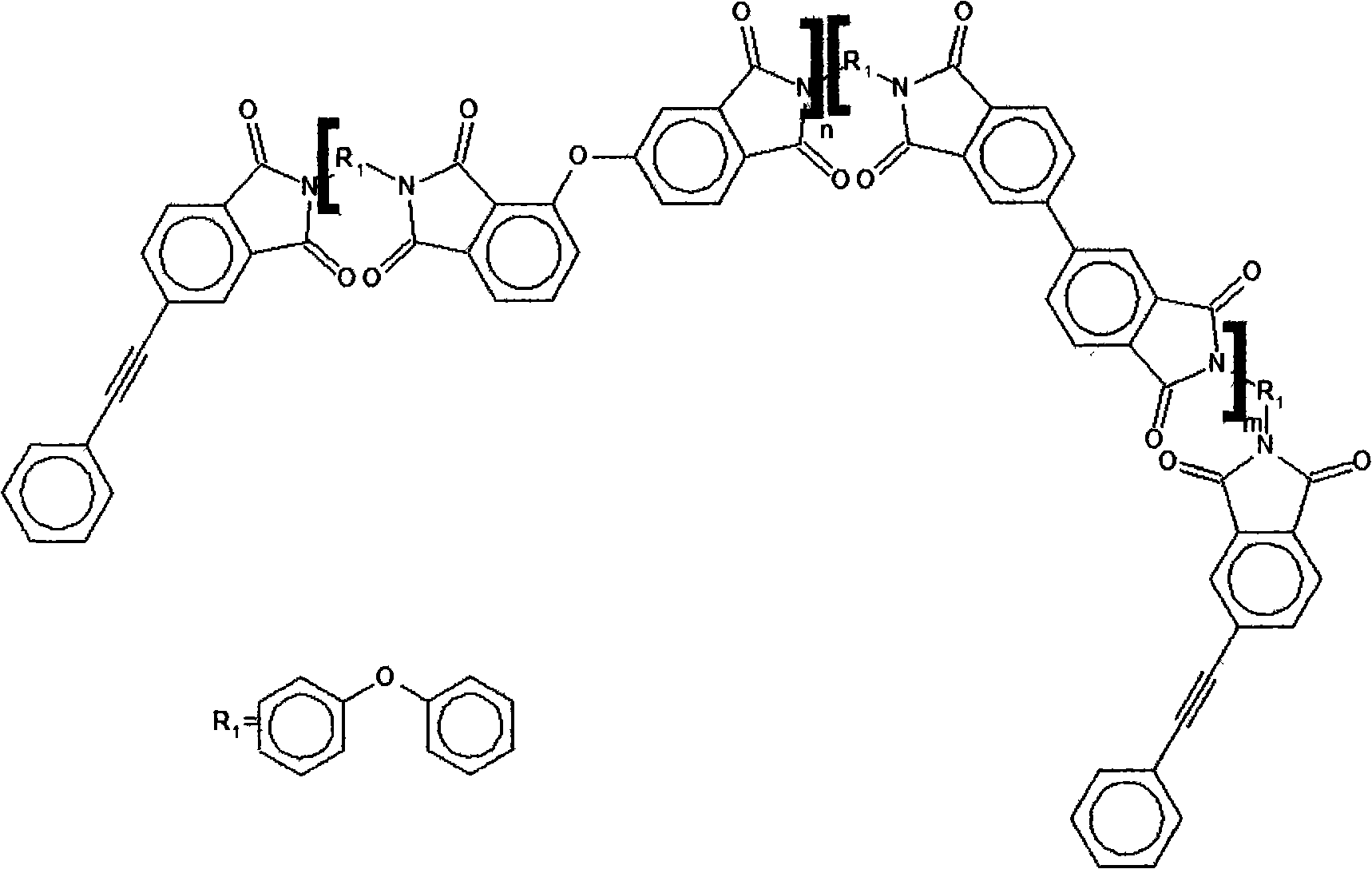

Method used

Image

Examples

Embodiment 1

[0023] Add 220g (1.1mol) of 4,4'-ODA and 2300ml DMAc to a three-necked 4-liter flask equipped with mechanical stirring, nitrogen inlet-thermometer and vent tube, and stir to dissolve with nitrogen gas, then add 93g (0.3mol) a-ODPA With 206g (0.7mol) BPDA, react at room temperature for 10 hours to obtain a polyamic acid solution, then add 49.6g (0.2mol) PEPA to react for 14 hours, and obtain a polymerization degree of n+m=10, n / m=3 / 7 imide oligomers. Then add 34g KH550 and 341g 60mm chopped glass fiber, after kneading and impregnation, heat treatment at 100°C, 160°C, 200°C, and 250°C for 5 hours respectively to obtain a pre-pressed polyimide glass fiber composite material with a volatile content of 0.5% by weight material. The performance of the spline obtained after hot molding is: unnotched impact strength 210.8KJ / m 2 , Flexural strength 1012.4MPa, flexural modulus 38.3GPa, tensile strength 508.0MPa, elongation at break 0.79%.

Embodiment 2

[0025] Except adding 4,4'-ODA222g (1.11mol), 62g (0.2mol) a-ODPA and 235g (0.8mol) BPDA, obtain polyamic acid solution at room temperature reaction 14 hours, then add 55g (0.22mol) PEPA reaction 10 hours, an imide oligomer with a degree of polymerization of n+m=4 and n / m=1 / 4 was obtained. Then add 25g KH550 and 252g 60mm chopped glass fiber, after kneading and impregnation, heat treatment at 100°C, 160°C, 200°C, 250°C for 3 hours respectively to obtain a polyimide glass fiber composite material with a volatile content of 1% by weight. Except the material, other operation steps and formula are exactly the same as embodiment 1, and the result spline performance is: unnotched impact strength 168KJ / m 2 , Flexural strength 596MPa, flexural modulus 28.5GPa, tensile strength 322MPa, elongation at break 0.83%.

Embodiment 3

[0027] In addition to adding 4,4'-ODA120g (0.6mol), 155g (0.5mol) a-ODPA and 149g (0.5mol) BPDA, reacted at room temperature for 6 hours to obtain a polyamic acid solution, then added 49.6g (0.2mol) PEPA to react After 6 hours, an imide oligomer with a degree of polymerization of n+m=2 and n / m=1 was obtained. Then add 49g KH550 and 480g 60mm chopped glass fiber, after kneading and impregnation, heat treatment at 100°C, 160°C, 200°C, 250°C for 2 hours respectively to obtain a polyimide glass fiber composite material with a volatile content of 2% by weight. Outside the material, other operation steps and formula are exactly the same as embodiment 1, and the result spline performance is: unnotched impact strength 106KJ / m 2 , Flexural strength 454MPa, flexural modulus 22.0GPa, tensile strength 259MPa, elongation at break 0.86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unnotched impact strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com