Pigment disperse sizing agent and electrophoretic paint

A technology for pigment dispersion and electrophoretic coatings, which is applied in pigment slurry, electrophoretic coatings, epoxy resin coatings, etc., can solve problems such as insufficient redispersibility of coatings, achieve excellent storage stability, excellent finishing, and achieve temporary stop effect

Active Publication Date: 2010-09-08

KANSAI PAINT CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when Patent Document 3 is applied to an electrophoretic paint for obtaining a white coating film containing titanium dioxide with a large specific gravity or an electrophoretic coating for obtaining a brown coating film using iron oxide, it is difficult to obtain a long time in the coating production line, especially during continuous breaks, etc. If the stirring and circulation of the electrophoretic coating are stopped for a long time, the redispersibility of the coating is insufficient during re-operation. Therefore, pitting and depressions occur on the electrophoretic coating surface of the coated article, especially on the horizontal surface, and need to be improved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

manufacture example 1

manufacture example 2

manufacture example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Login to View More

Abstract

The purpose of the invention is to provide a pigment dispersing paste capable of saving energy of coating apparatus and saving redispersibility of dye of the apparatus and electrophoretic paint. Specifically, the invention relates to a pigment dispersing paste for electrophoretic paint, containing pigment dispersing resin (A), tinting color (B), color filler (C) and cellulose composition (D); responding to the solid component 100 weight parts of the resin (A), the paste is characterized by containing: (1) 60 to 800 weight parts of (b1) titanium dioxide coated by 0.1 to 10.0 weight parts of Al2O3 without SiO2 on 100 weight parts of titanium dioxide as matrix; and / or (b2) ferric oxide as the of tinting color (B); (2) 2 to 200 weight parts of micro barium sulfate with the mean grain size of linear particle being 0.01 to 0.1 micron as the color filler (C); and (3) 1 to 50 weight parts of cellulose composition (D).

Description

technical field The present invention relates to a pigment dispersion slurry excellent in redispersibility of pigments capable of saving energy and equipment for coating equipment, and an electrophoretic paint using the pigment dispersion slurry. Background technique Electrophoretic paint is widely used as a primer for metal products such as automobile bodies because of its excellent painting workability and good rust resistance. Pigment dispersion slurries used in such electrophoretic coatings are usually stored in containers or cylindrical tanks and kept in warehouses after production. However, if they are not stirred regularly, the pigments may settle and use may be hindered. Especially when transporting foreign coating equipment, since the pigment dispersion slurry put into the cylindrical tank is in a state of non-stirring for a long time, it is urgent to improve the storage stability of the pigment dispersion slurry. On the other hand, in order to prevent the sedimen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

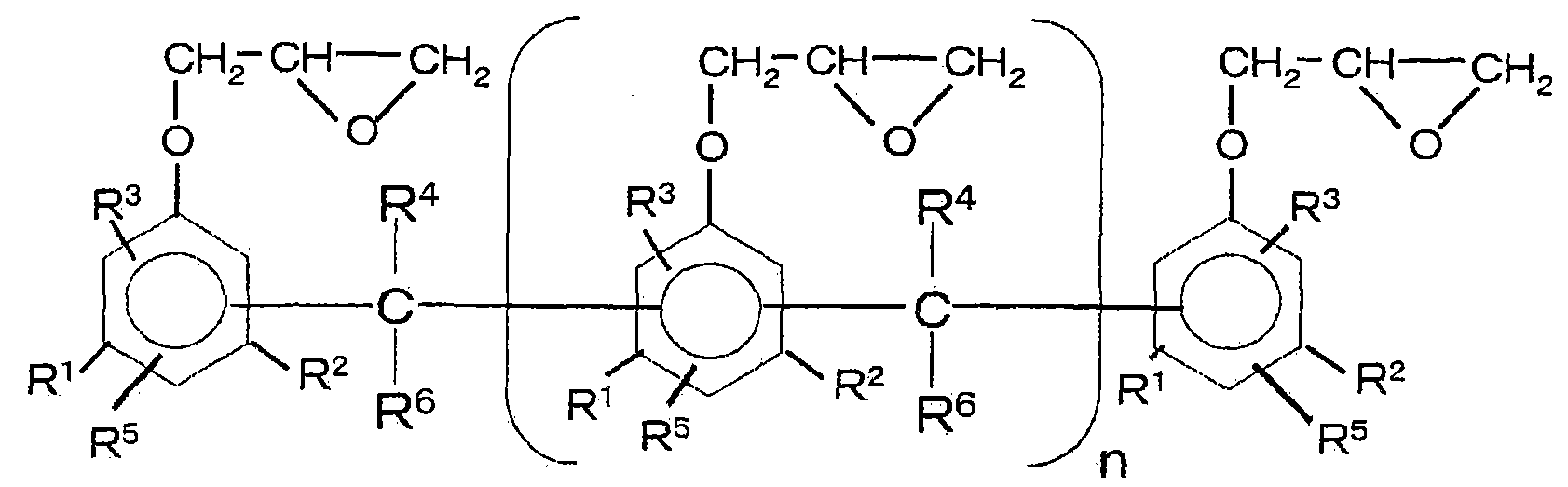

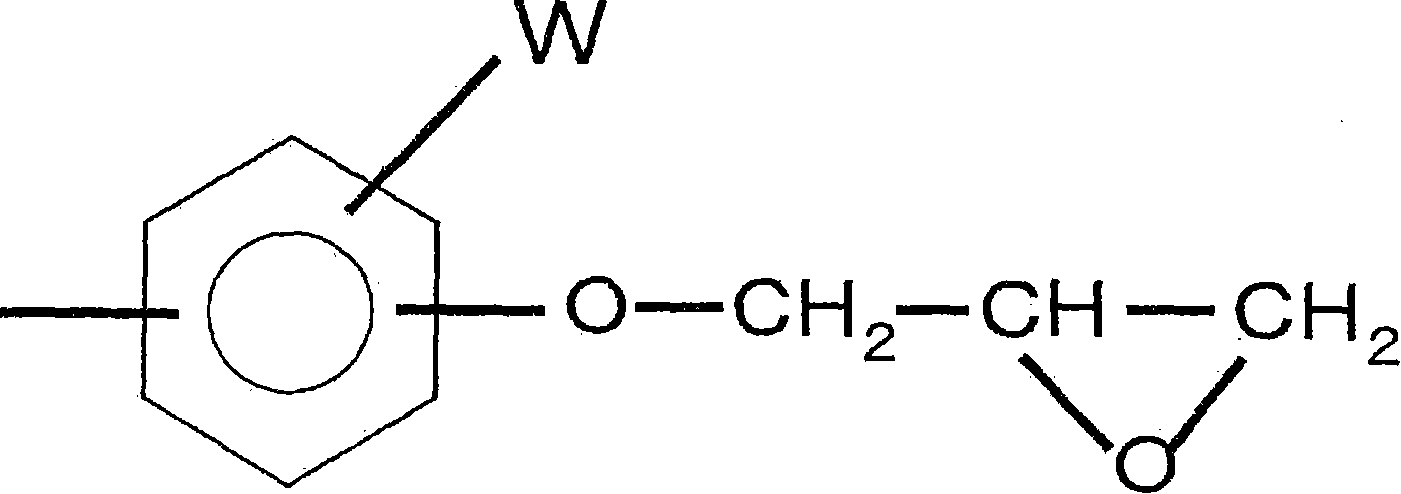

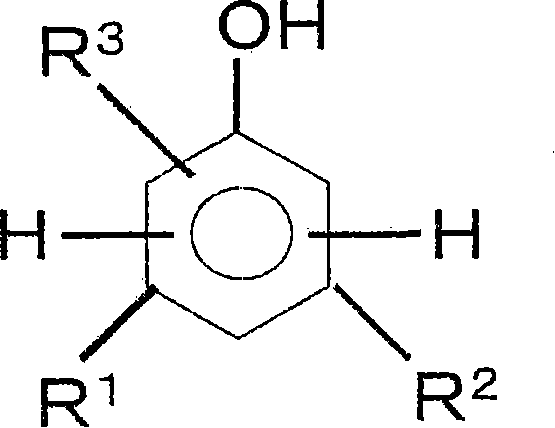

IPC IPC(8): C09D17/00C09D5/44C09D163/00

Inventor 粕川高久片冈晴彦大家正裕

Owner KANSAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com