Tough sintering epoxy powder coating and preparation thereof

A technology for sintering epoxy powders and coatings, applied in powder coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of low cross-linking, insignificant toughening effect, poor leveling, etc., to meet anti-corrosion requirements , High impact resistance, the effect of increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

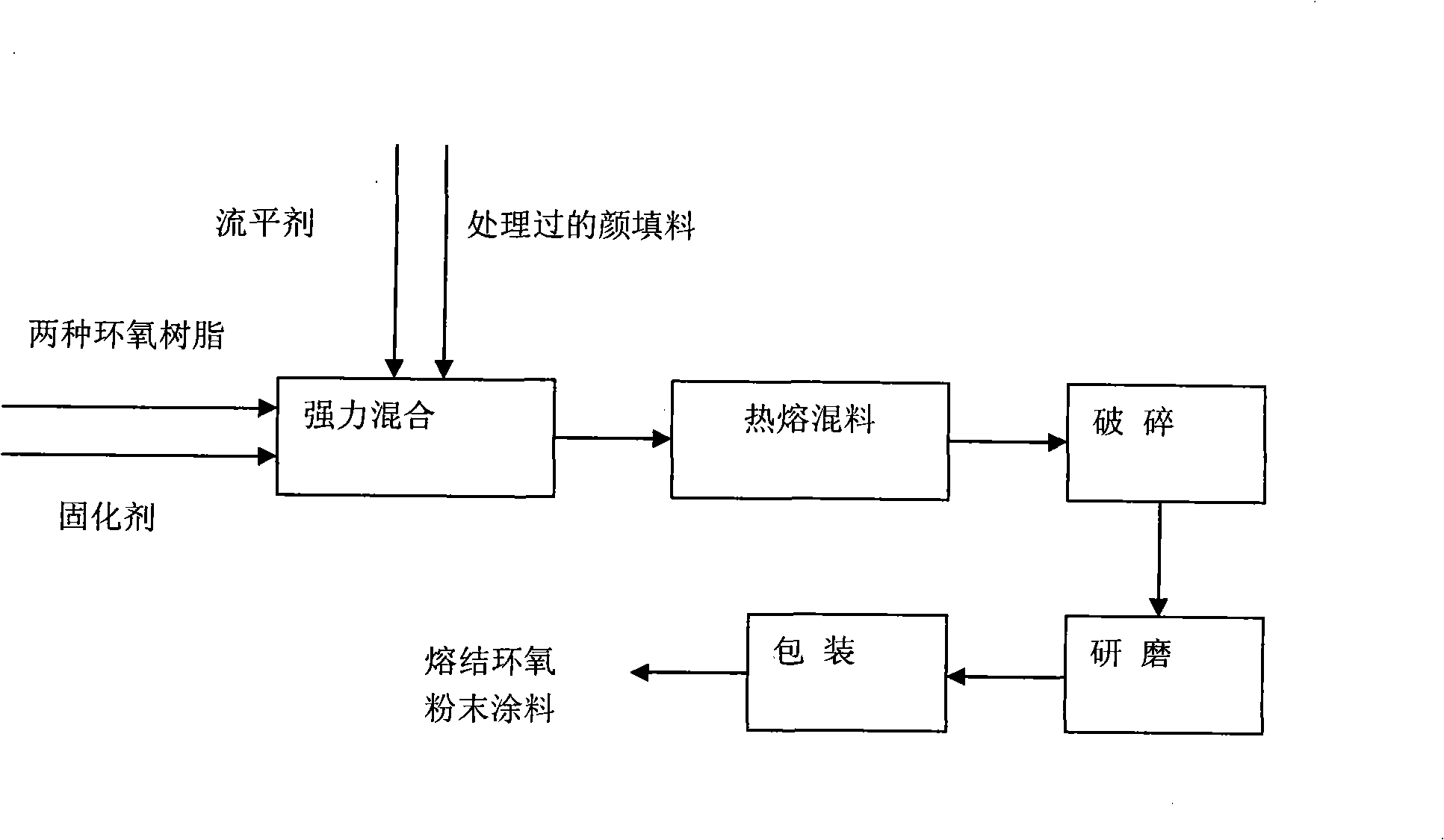

Image

Examples

Embodiment 1

[0023] A solution of 12.5 g of silane composition A and 2 g of solvent B was added to 100 g of titanium dioxide, mixed in a high-speed mixer for 30 minutes, and air-dried to obtain treated titanium dioxide powder.

Embodiment 2

[0025] Add 30kg of novolac epoxy resin, epoxy resin E-1220g, 15kg of curing agent, and 2kg of leveling agent into a high-speed mixer and mix for 2 minutes, add 33kg of silane-treated titanium dioxide powder, and mix for 5 minutes at high speed; premixed materials are added to extrude Machine melt extrusion, the feeding section temperature is 90°C, the melting section temperature is 100°C, the mixing section is 110°C, the discharge section is 100°C, the extruder speed is controlled at 80rpm, and the tablet is compressed and cooled on the air-cooled crawler tablet crusher. , crushing, in the crushing mill, the product is obtained by crushing, grading, cyclone separator separation and sieving, and the superfine powder is removed by cyclone separation. The product particle size control: 150 μm sieve powder ≤ 3%, 250 μm sieve powder ≤ 0.2%.

[0026] Toughened epoxy powder coating technical index that the present invention makes

[0027] indicators

Test results

T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com