Method for manufacturing chemical paraffin cleaner

A manufacturing method and technology of a wax remover, which is applied in the direction of cleaning equipment, earth cube drilling, wellbore/well parts, etc., can solve the problems of paraffin deposition at the bottom of the well, troublesome production, difficult transportation, etc., and achieve high wax removal efficiency, The effect of low application cost and large heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

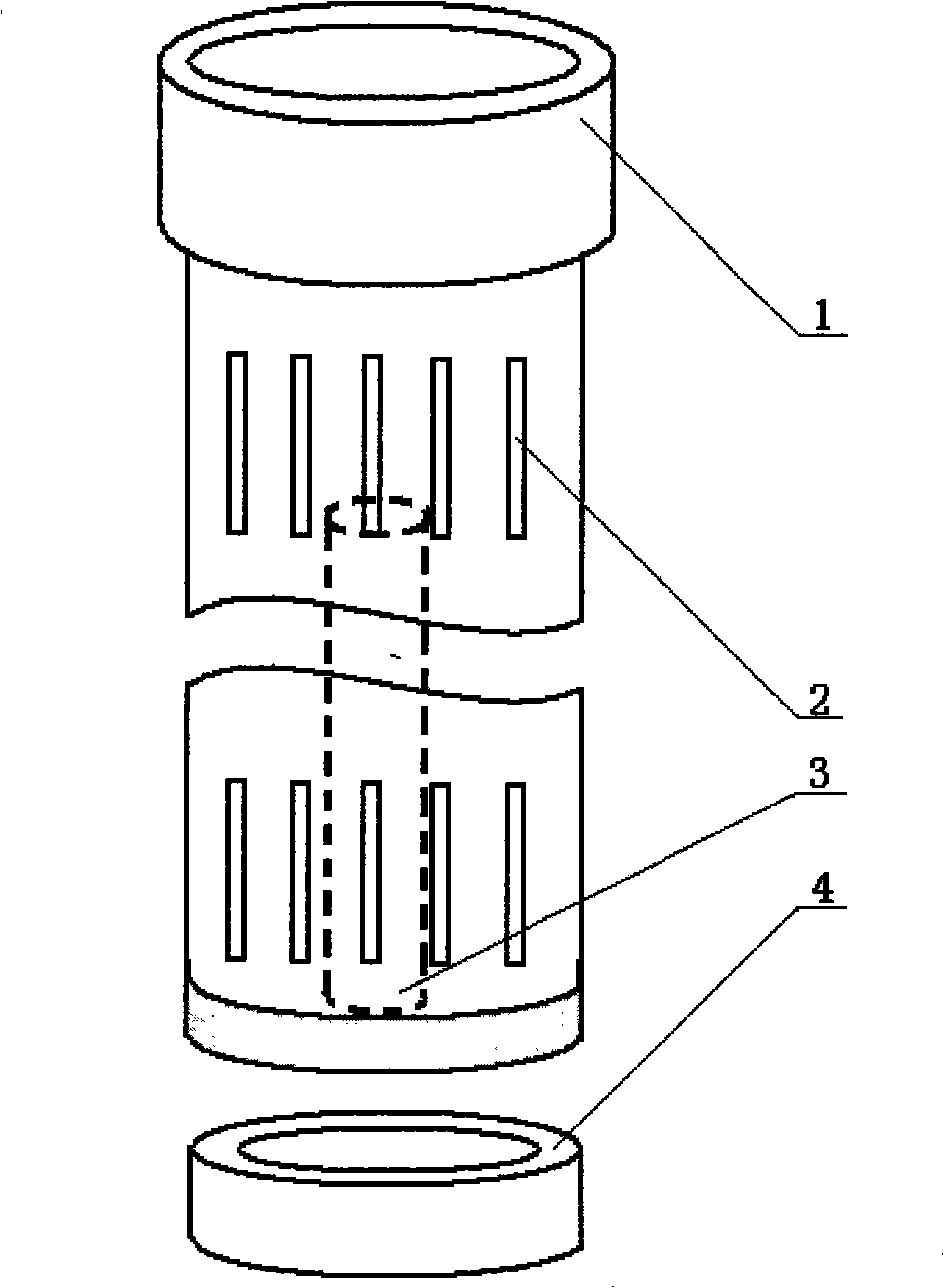

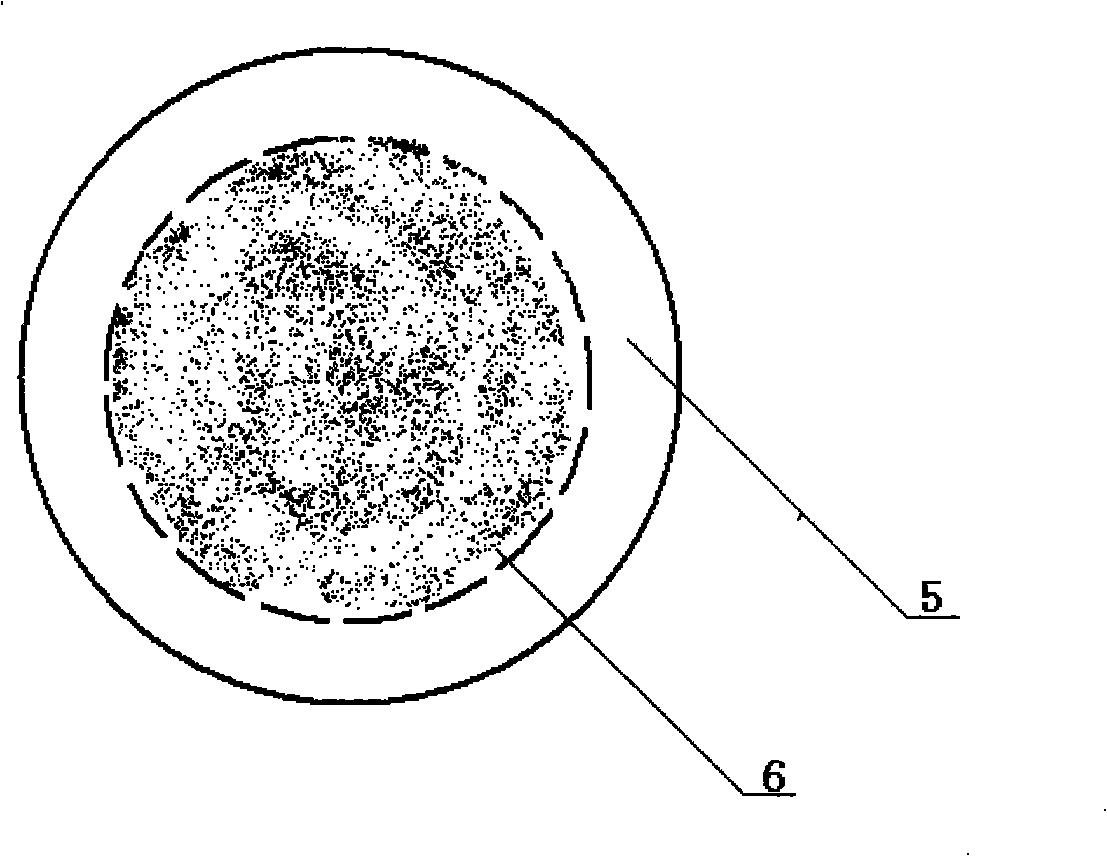

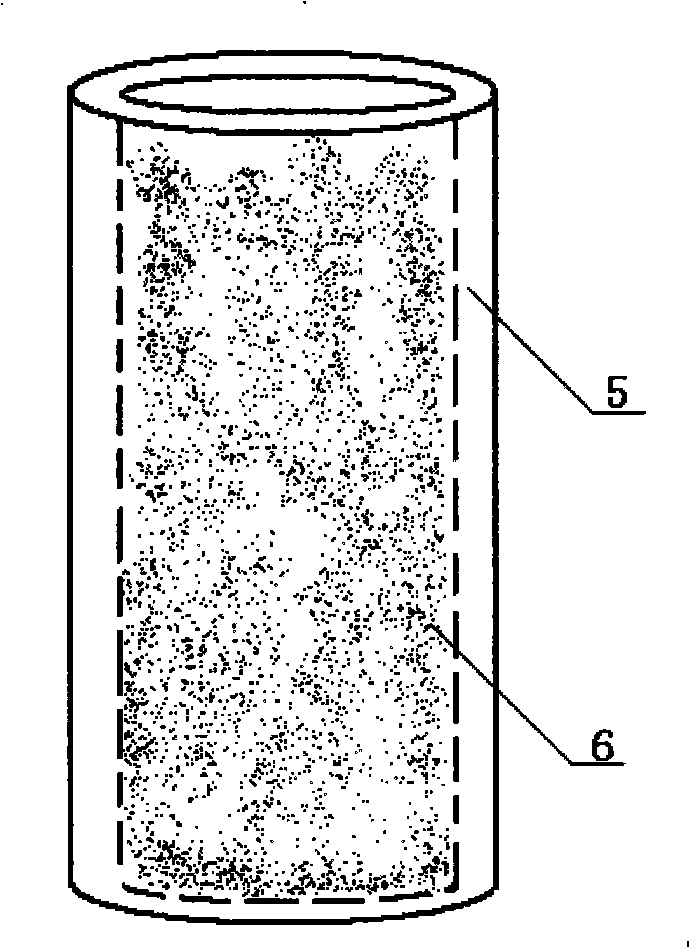

[0014] A method for manufacturing a chemical wax remover. The main body is composed of a cylindrical tube with a limiter 1 at the top, which is connected to the oil tube, and the diameter is suitable for the oil tube. There is a wall opening 2 on the main tube, and the wall opening 2 has 3-- 5 rows, 20-50 wall openings are evenly distributed in each row 2. The bottom end of the main pipe is a sealing plug 4, and the inside is equipped with a wax remover 3. For electric pump wells and self-spray wells, the wax remover 3 is cylindrical, and the outer diameter is smaller than the inner diameter of the main pipe. The thickness is not more than 0.1mm, and the chemical reagent 6 is installed inside.

[0015] Fix the paraffin remover 3 at the bottom of the tubing through the limiter 1 to reach the target oil layer, clean the strata of newly opened oil wells,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com