Spectrometer and method for correcting the same

A spectrometer and light source technology, applied in the field of spectrometers, can solve problems such as small dynamic range, unstable response of photomultiplier tubes, and poor measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

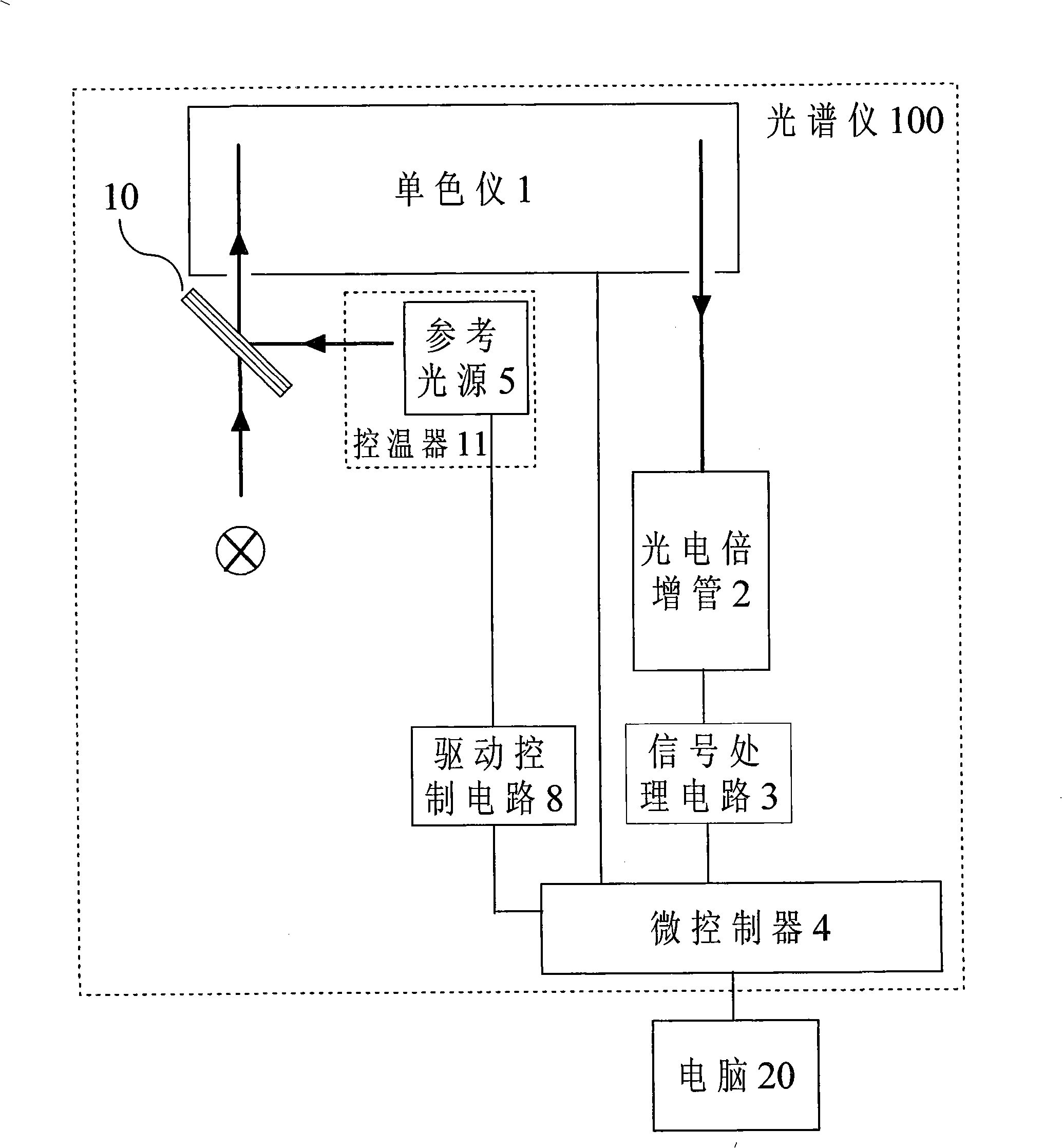

[0032] Such as figure 1 As shown, the spectrometer is composed of monochromator 1, photomultiplier tube 2, signal processing circuit 3, microcontroller 4 and reference light source 5 and other components. The dotted line part in the figure is the structure of the spectrometer 100 . The monochromator 1 divides the light to be measured introduced by the incident slit into monochromatic light, and the photomultiplier tube 2 senses the monochromatic light emitted by the monochromator 1 to measure the spectral power distribution of the light to be measured, and the photomultiplier tube 2 passes the signal processing The circuit 3 is electrically connected to the microcontroller 4 , and the reference light source 5 can emit reference light to illuminate the incident slit of the monochromator 1 .

[0033] The present invention specifically includes a monochromator 1 for separating the measured light into monochromatic light, a photomultiplier tube 2 for receiving monochromatic light...

Embodiment 2

[0043] Such as Figure 4 As shown, another embodiment of the spectrometer is: on the basis of the above-mentioned spectrometer structure, a reference detector 6 for receiving reference light is added, and its position is arranged on the opposite side of the reference light source 5, and the reference light source 5 emits reference light. Irradiated on the reference detector 6 and the incident slit of the monochromator 1 respectively, the response signal size of the reference detector 6 to the reference light is proportional to the intensity of the reference light, and this signal is used as the reference signal (replacing the driving current of the reference light source ), combined with the response signal of the photomultiplier tube 2 to the reference light, the absolute sensitivity of the photomultiplier tube 2 is corrected.

[0044] More specifically, the reference detector 6 is a silicon photodiode, and its electrical signal is sent to the microcontroller 4 through a sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com