Full bridge converter with zero voltage and zero current

A zero-voltage, zero-current, DC-DC technology, applied in high-efficiency power electronic conversion, conversion of DC power input to DC power output, adjustment of electrical variables, etc., can solve the loss of duty cycle, increase circuit on-state loss, saturated inductance The problem of difficult selection of magnetic materials, etc., achieves the effect of simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

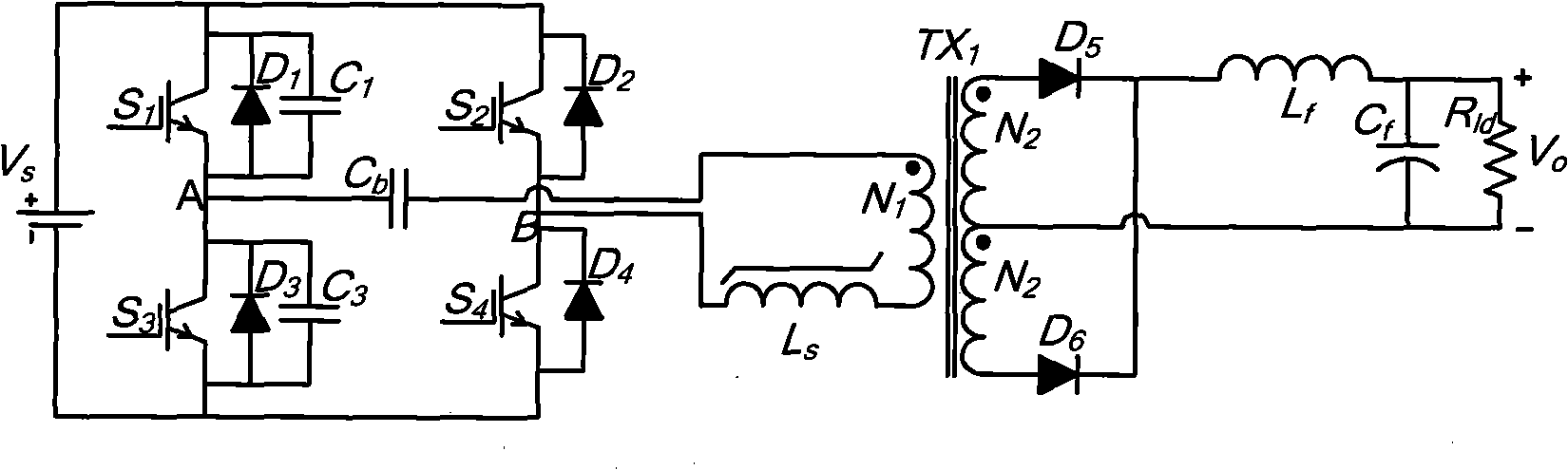

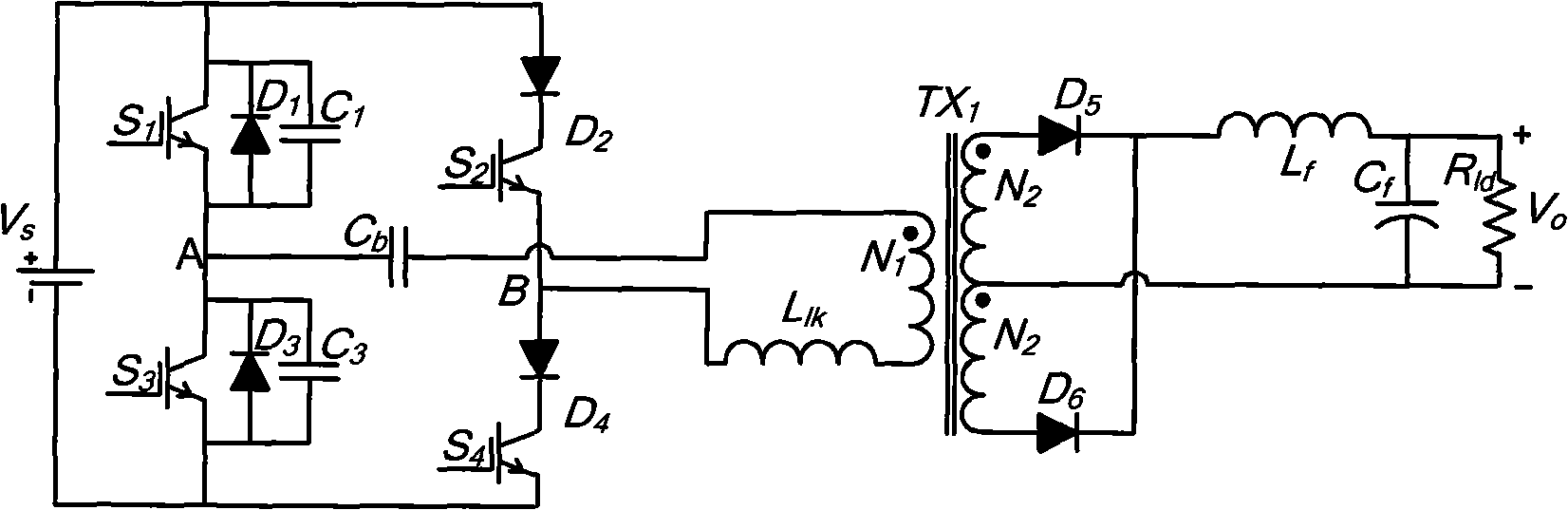

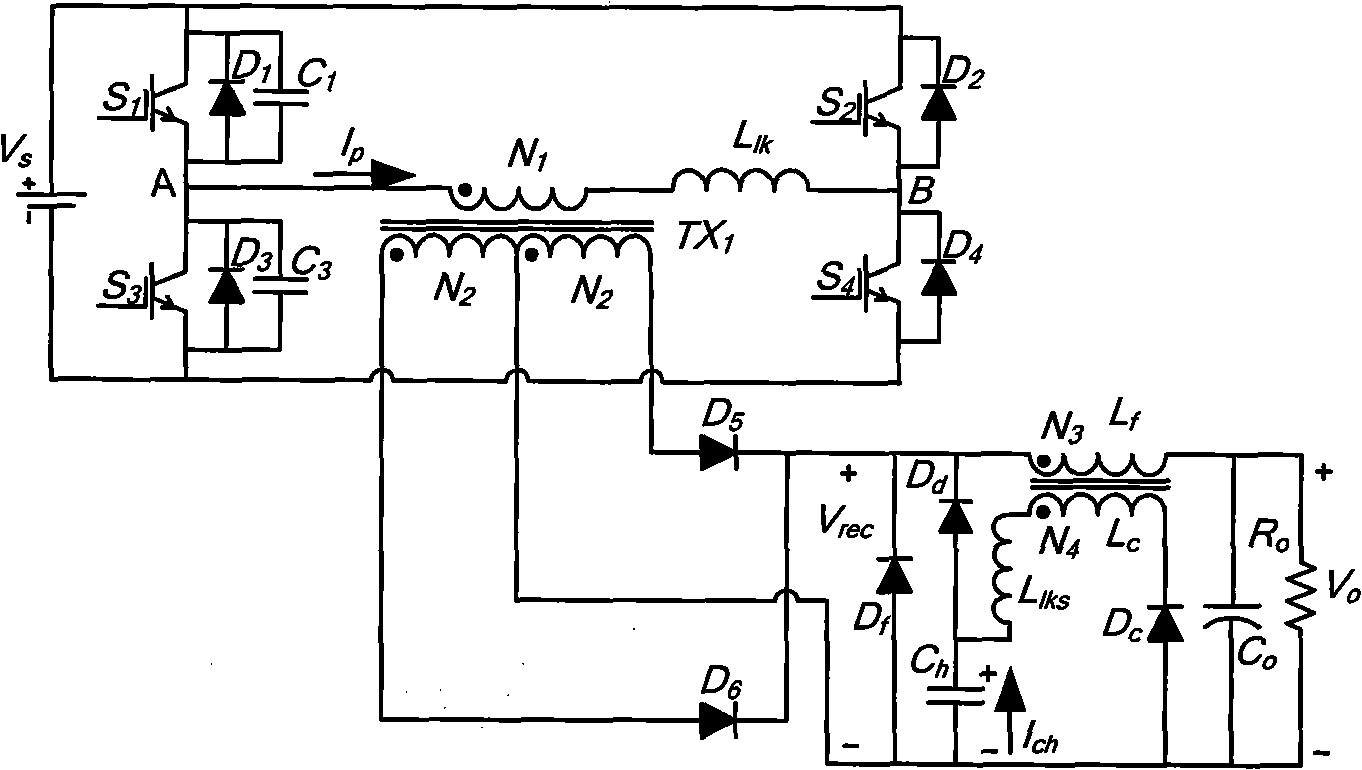

[0011] Such as image 3 As shown, the main circuit includes four power transistors S 1 , S 3 , S 2 , S 4 , nine diodes D1 ~ D6, D d 、D f 、D C , three capacitors C 1 、C 3 and Ch, transformer TX 1 , a full-bridge PWM converter composed of filter inductor Lf and power supply Vs. In the super forearm switch tube S 1 , S 3) and the lagging arm switch S 2 , S 4 Both ends of the anti-parallel diode D 1 、D 3 、D 2 、D 4 , and then in the super forearm switch S 1 , S 3 Upper parallel capacitor C 1 、C 3 ; in transformer TX 1 The end with the same name on the primary side is connected to the switch tube S 1 on the transmitter side of the transformer TX 1 The non-identical end of the primary side is connected to the inductor Llk; in the transformer TX 1 The terminal with the same name on the secondary side is connected to the diode D 6 The positive pole of the secondary side is connected to the diode D with the non-identical end of the secondary side 5 positive pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com