Nutrition fortification rice rich in organic selenium, zinc and chromium and production method thereof

A nutrition-enhanced, selenium-enriched rice technology, applied in fertilization methods, food preparation, food science, etc., can solve the problems of low selenium and zinc content in rice, increased labor costs, and inability to reach the grains, so as to promote photosynthesis, Increase grout strength and facilitate absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

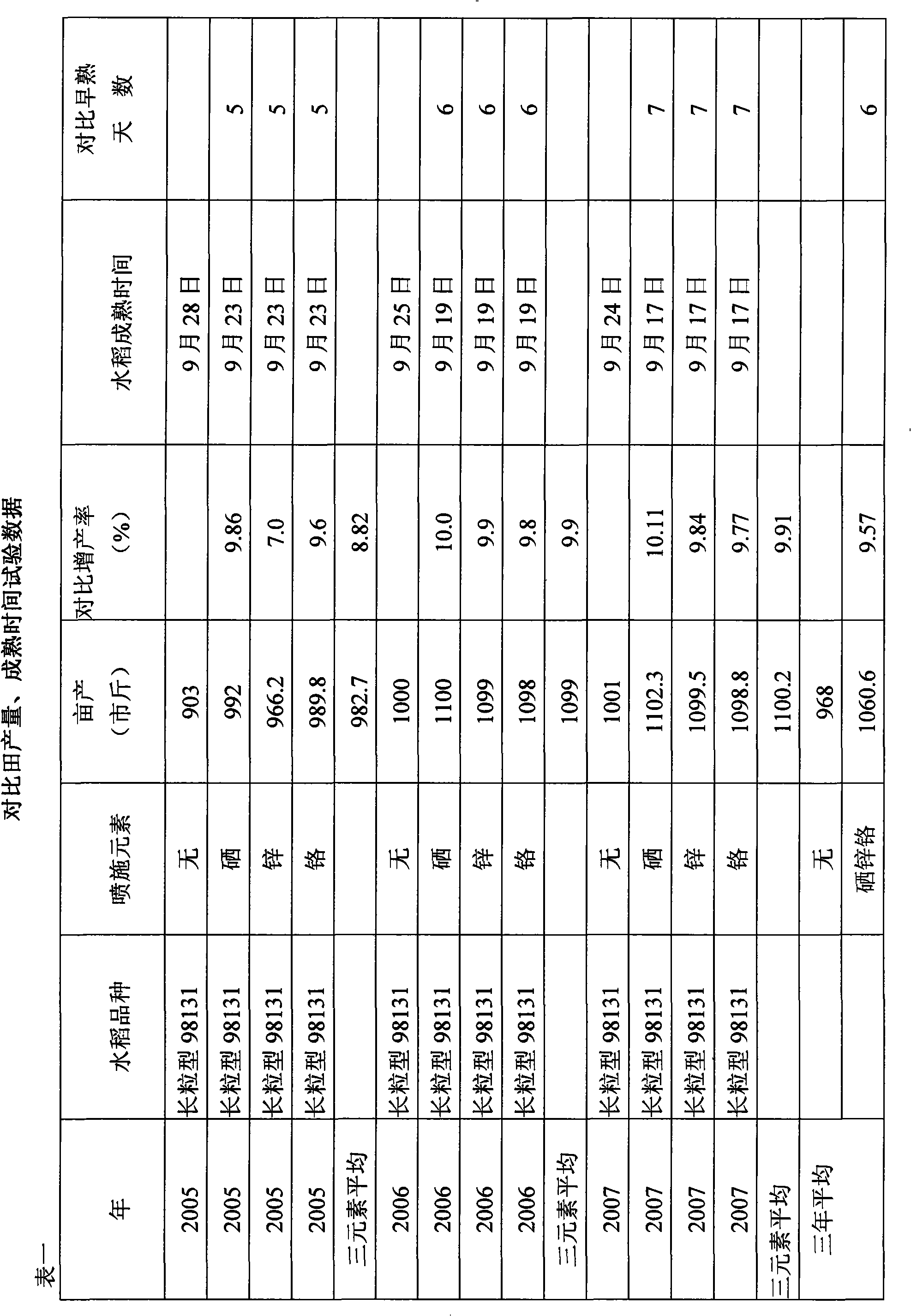

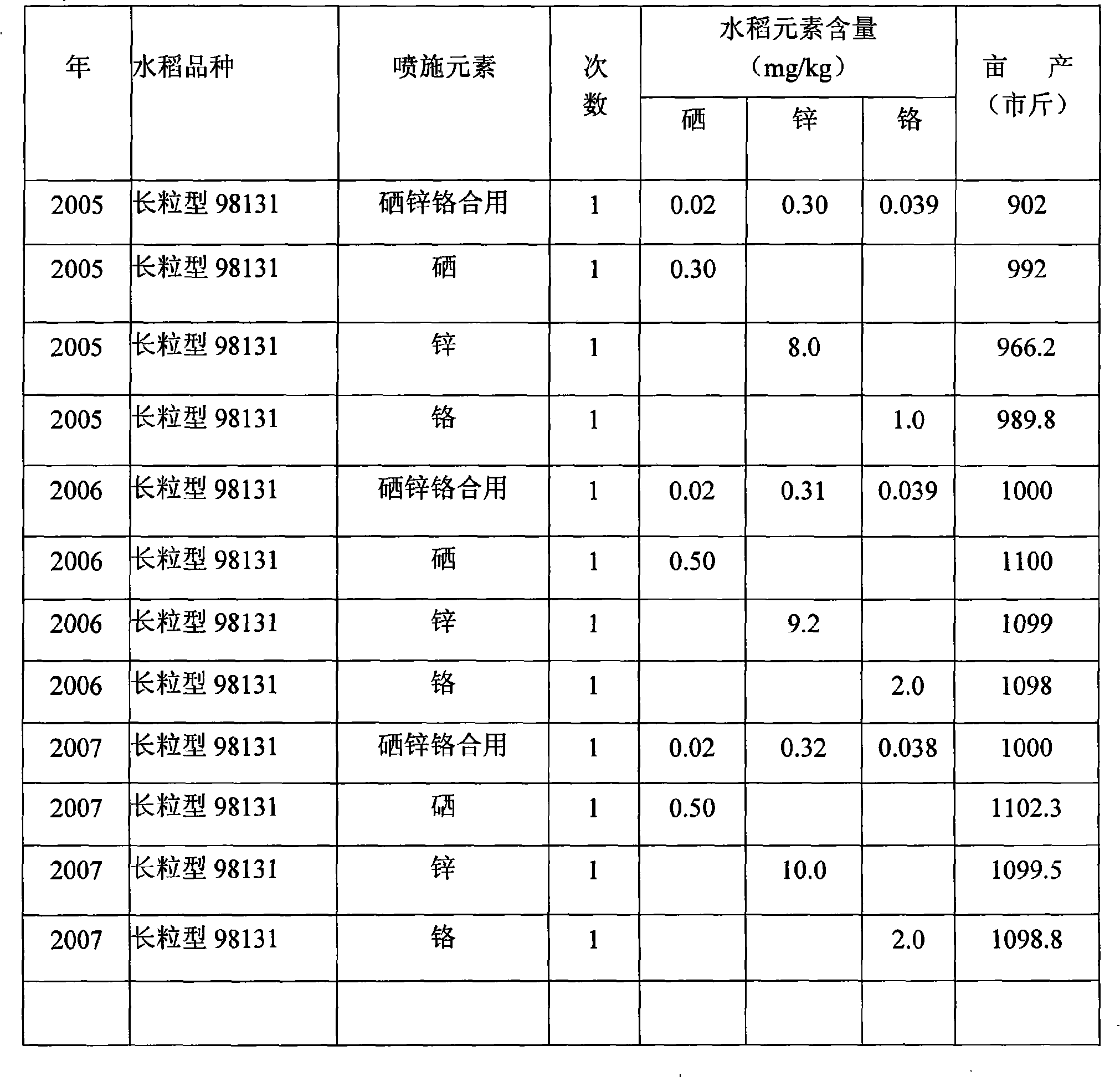

[0023] 1% selenium dioxide, 1.5% methionine, 5% fulvic acid and 92.5% water are stirred and dissolved to form a selenium solution. 20% zinc sulfate with 7 crystal waters, 1.5% methionine, 5% fulvic acid and 73.5% water are dissolved by stirring to form a zinc solution. 15% by weight of organic trivalent chromium, 3% of fulvic acid and 82% of water are stirred and dissolved to form a chromium solution. The three trace element solutions were sprayed on different plots in the field. Field application rates are: chromium solution, 30g per mu, diluted with 30kg of water; zinc solution, 30g per mu, diluted with 30kg of water; selenium solution, 33g per mu, diluted with 33kg of water.

[0024] A comparative test of three plots in Ping'an Town, Qing'an County, Heilongjiang Province under the same conditions. The plots sprayed with multi-element fertilizers were more effective than the rice of the same variety without spraying. The test data at harvest time: the selenium content of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com