Method for preparing high quality titanium white

A high-quality, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the method of removing mechanical impurities and colloidal particles from solid adsorbates. The effect is not ideal and other problems, to achieve the effect of eliminating negative effects, improving achromatic power and whiteness, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

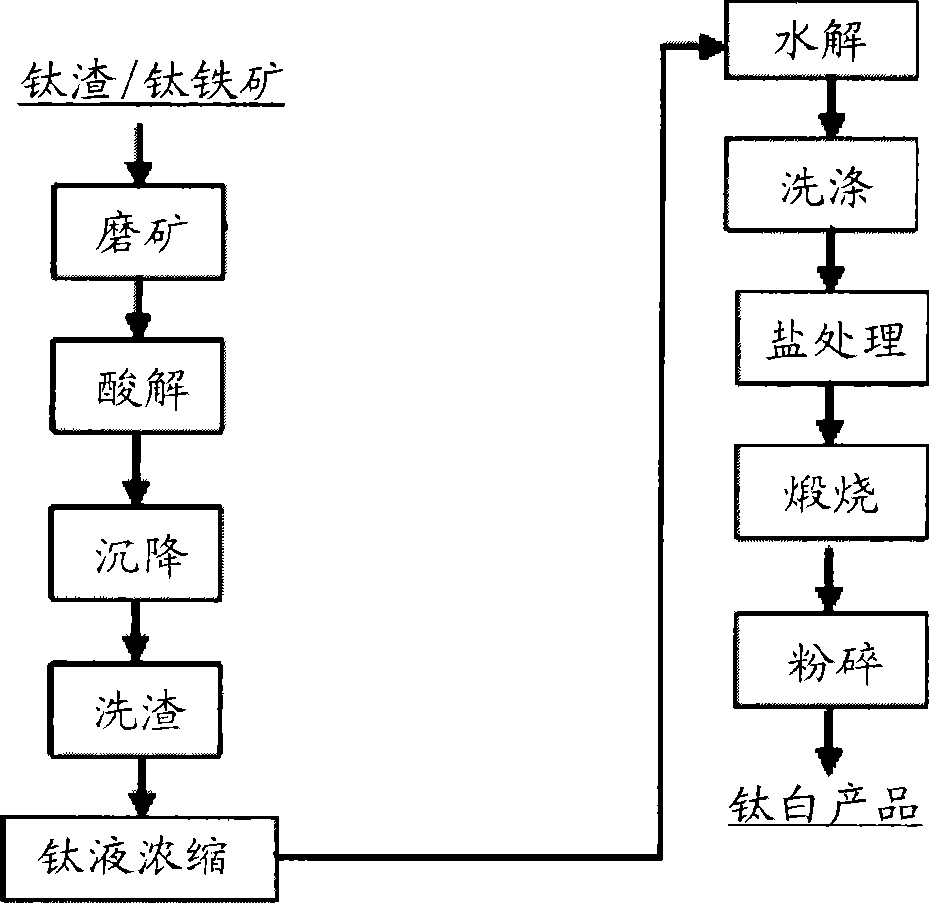

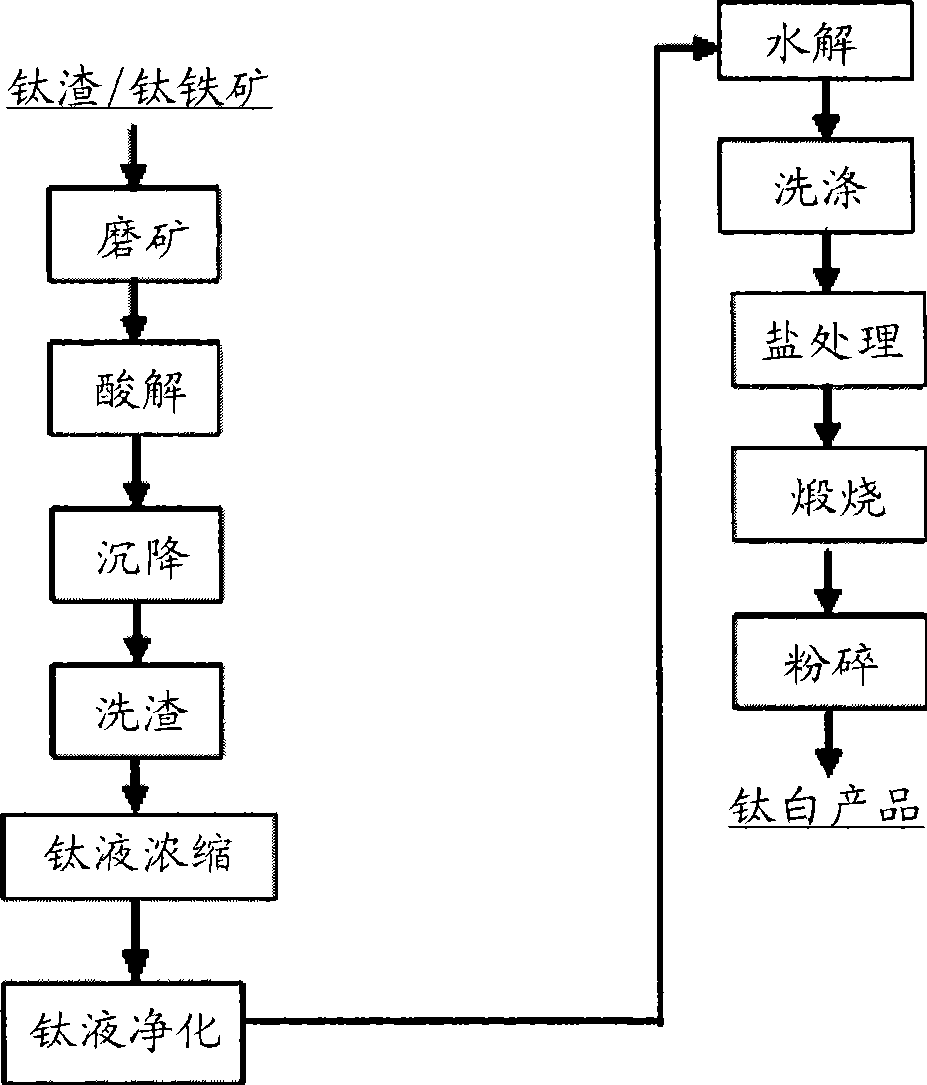

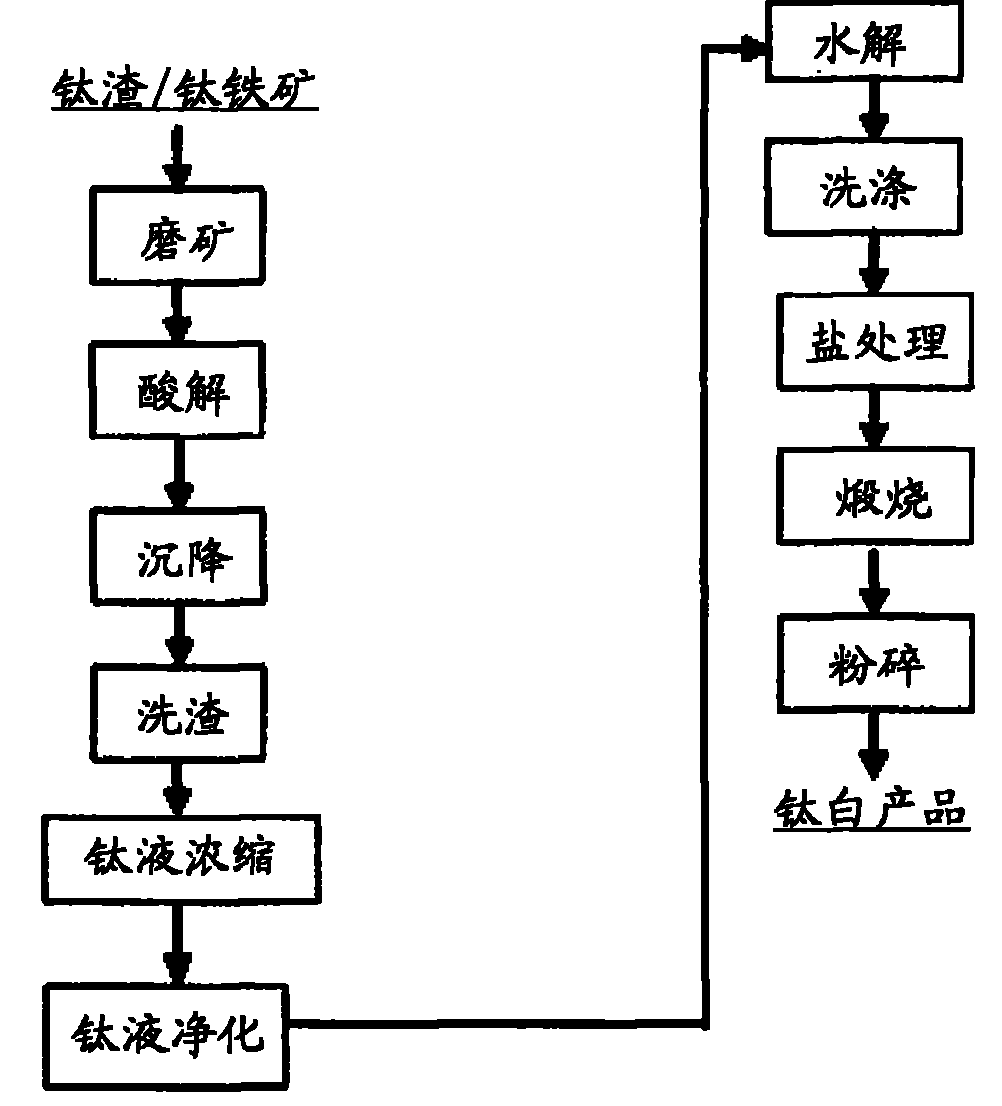

[0035] To contain 74.05% TiO 2 , 10.44% SiO 2 , 7.65% TFe (full iron), 2.82% Al 2 o 3 , 1.80% MgO, 0.70% CaO and other impurities (the above are weight percentages) of high titanium slag as raw material, according to figure 2 The process flow shown in the preparation of titanium dioxide. Among them, after ore grinding, acidolysis, sedimentation, slag washing, and concentration, the concentrated titanium liquid is cooled to 20°C, and a suspension is prepared with α-type cellulose and water at a volume ratio of 1:4. , add the suspension into the funnel covered with filter paper, so that the suspension evenly forms a layer of filter cake on the filter paper, and then filter the cooled concentrated titanium solution through the filter cake in a natural state, wherein, α-type The amount of cellulose is 0.1% of the amount of hydrolyzed titanium solution. The concentrated titanium solution after fine filtration is hydrolyzed (three times) according to the hydrolysis system of t...

Embodiment 2

[0037] according to figure 2 The process flow shown for the production of titanium dioxide to contain 74.05% TiO 2 , 10.44% SiO 2 , 7.65% TFe (full iron), 2.82% Al 2 o 3 , 1.80% MgO, 0.70% CaO and other impurities (above are percentages by weight) high titanium slag as raw material, the titanium liquid after concentration is cooled to 45 ℃ situation, according to the method identical with embodiment 1 with α-type cellulose forms a filter cake, and the difference from Example 1 is that the amount of α-type cellulose is 1.2% of the amount of hydrolyzed titanium solution. Then, filter the cooled concentrated titanium solution through the filter cake in a natural state at 45±5°C. The concentrated titanium solution after fine filtration is hydrolyzed (three times) according to the hydrolysis system of the prior art, and finally No. 2 titanium dioxide product is obtained.

Embodiment 3

[0039] according to figure 2 The process flow shown for the production of titanium dioxide to contain 74.05% TiO 2 , 10.44% SiO 2 , 7.65% TFe (full iron), 2.82% Al 2 o 3 , 1.80% MgO, 0.70% CaO and high titanium slag of other impurities (the above are weight percentages) as raw material, the titanium liquid after concentration is under 80 ℃ situation, according to the method identical with embodiment 1 with α-type The cellulose forms a filter cake, and the difference from Example 1 is that the amount of α-type cellulose is 1.5% of the amount of hydrolyzed titanium solution. Then, filter the cooled concentrated titanium solution through the filter cake in a natural state. The concentrated titanium solution after the fine filtration is hydrolyzed (three times) according to the hydrolysis system of the prior art, and the No. 3 titanium dioxide product is finally obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com