High modulus asphalt concrete additive agent

A technology of asphalt concrete and additives, which is applied in the field of polymer functional materials, can solve the problems of low temperature, asphalt concrete resistance to load deformation, limited recovery ability, fatigue fracture, etc., and achieve low cost, saving non-renewable resources, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

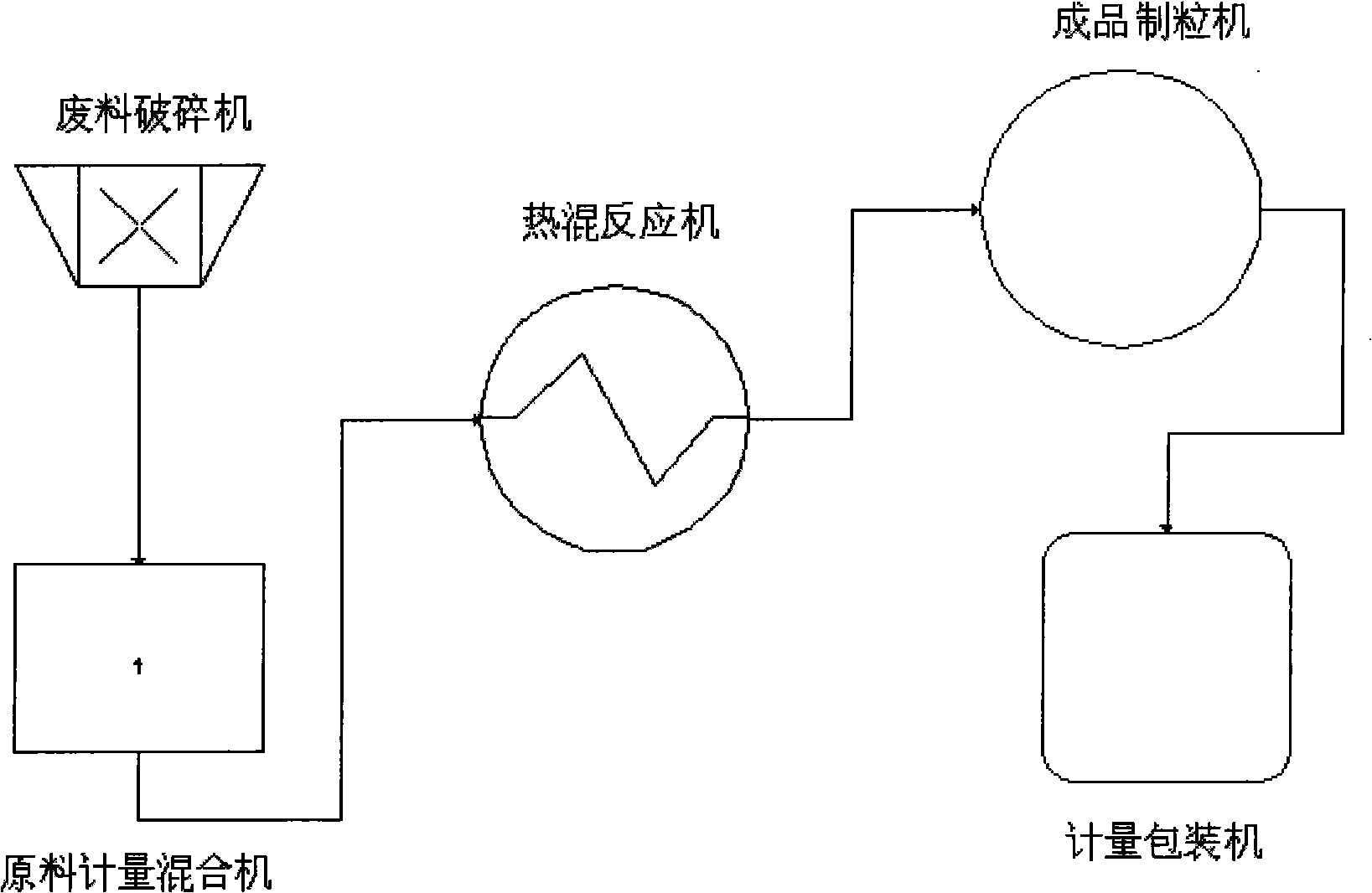

Method used

Image

Examples

example 1

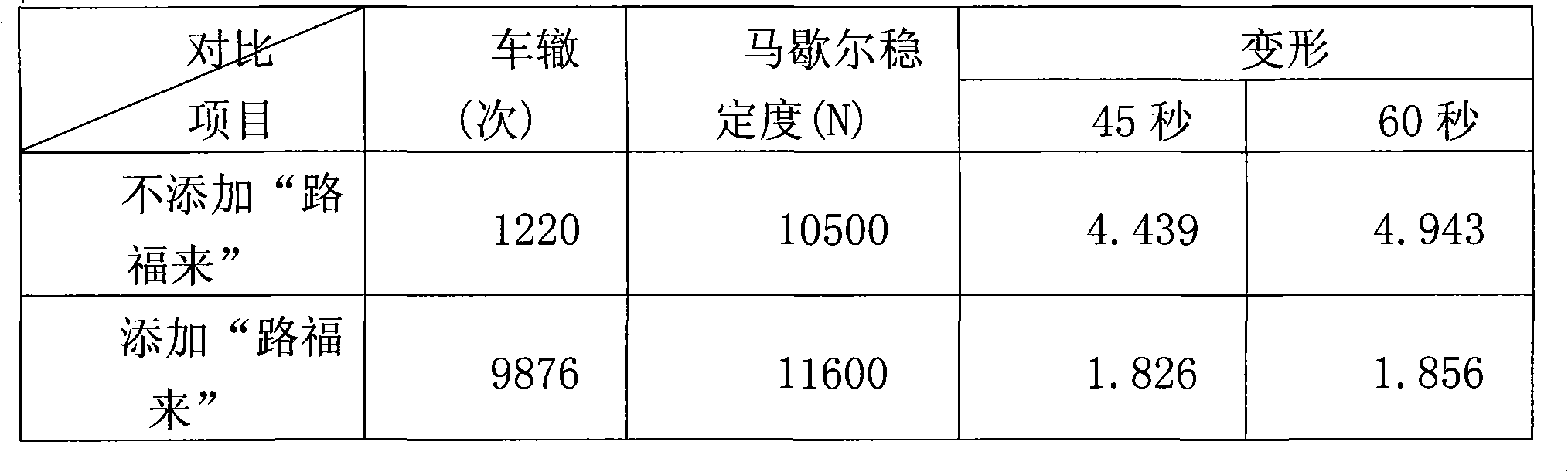

[0039] Example 1: Application on levee expressway with serious water intrusion

[0040] Experimental asphalt: Maoming 70#

[0041] Purpose of the experiment: Adding "Lufulai" and not adding "Lufulai" mixture experiment

[0042]

example 2

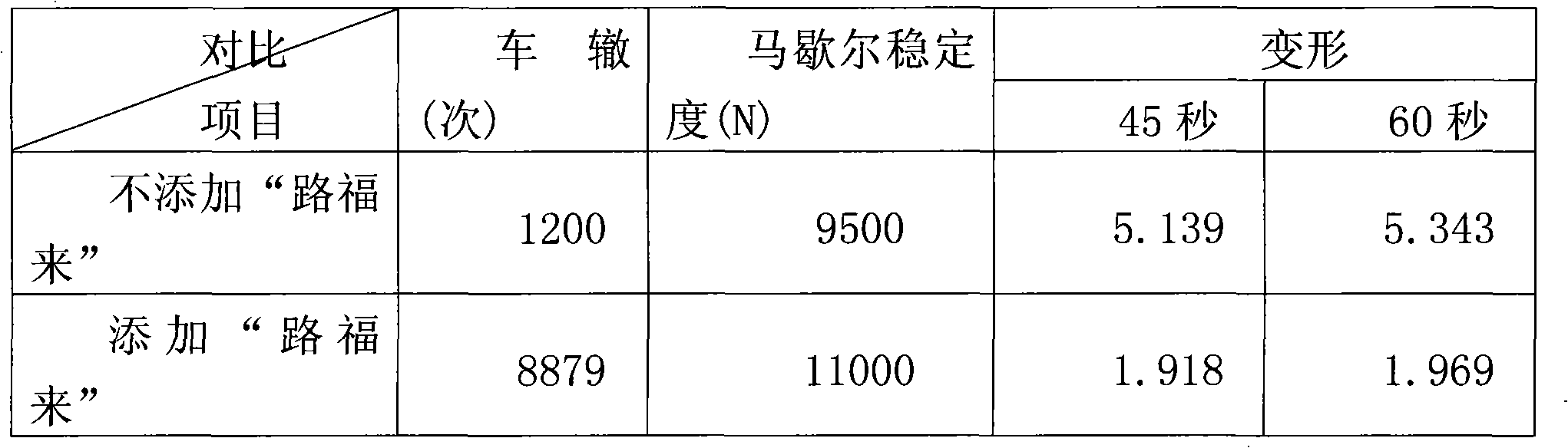

[0043] Example 2: Application on highway pavement

[0044] Experimental asphalt: Panjin 90#

[0045] Purpose of the experiment: Adding "Lufulai" and not adding "Lufulai" mixture experiment

[0046]

example 3

[0047] Example 3: Application on expressway viaduct deck

[0048] Experimental asphalt: Shell 70#

[0049] Purpose of the experiment: Adding "Lufulai" and not adding "Lufulai" mixture experiment

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com