A kind of asphalt mixture for road and preparation method thereof

A technology for asphalt mixture and road, which is applied in the field of asphalt mixture for road and its preparation, which can solve the problems of strengthening the limitations of road surface construction, increasing exhaust gas dust particles, and unfavorable environmental protection, so as to improve the synergistic effect of compounding and improve the interaction force, improving compactness and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

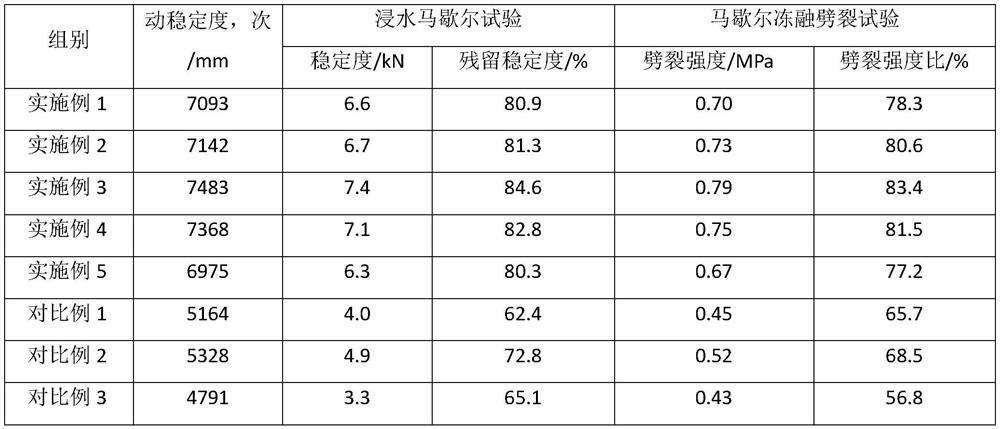

Examples

Embodiment 1

[0035] The present embodiment provides a kind of preparation method of asphalt mixture for road, comprising the following steps:

[0036] Step 1: Weigh 8kg of asphalt, 35kg of basalt gravel, 20kg of limestone gravel, 40kg of pumice, 10kg of blast furnace slag powder, 5kg of sand, 3kg of warm mixing agent, 0.3kg of recycled rubber, 0.2kg of Sepiolite fibers and 0.3kg of gypsum fibers. Among them, the mixture of basalt crushed stone, limestone crushed stone and pumice was sieved together. The pass rate of the sieve mesh with a sieve size of 4.75mm was 29.3%, and the pass rate of a sieve mesh with a sieve size of 9.5mm was 57.9%. The pass rate of the 13.2mm sieve is 82.4%, and the pass rate of the 19mm sieve is 100%. Preheat basalt crushed stone, limestone crushed stone and pumice to 135°C, add sepiolite fiber and polyvinyl alcohol fiber and dry mix at 140°C for 25s to obtain a dry mixed mixture.

[0037] Step 2: Add asphalt and warm mix agent to the dry mix obtained in Step 1,...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 mainly lies in: the preparation method of the road asphalt mixture of the present embodiment comprises the following steps:

[0040] Step 1: Weigh 9kg of asphalt, 50kg of basalt crushed stone, 25kg of limestone crushed stone, 30kg of granite crushed stone, 6kg of gabbro powder, 8kg of blast furnace slag powder, 4kg of pegmatite powder, 3.5 kg of warm mixing agent, 0.2kg of high-density polyethylene, 0.2kg of recycled rubber, 0.15kg of sepiolite fiber and 0.55kg of gypsum fiber. Among them, the mixture of basalt crushed stones, limestone crushed stones and granite crushed stones was sieved together. The pass rate of the sieve with a sieve size of 4.75mm was 34.8%, and the pass rate of a sieve with a sieve size of 9.5mm was 61.2%. The pass rate of the sieve with a hole size of 13.2 mm was 85.4%, and the pass rate of a sieve with a sieve size of 19 mm was 100%. Preheat basalt crushed stone, limestone crushed stone an...

Embodiment 3

[0043] The difference between this embodiment and embodiment 1 mainly lies in: the preparation method of the road asphalt mixture of the present embodiment comprises the following steps:

[0044] Step 1: Weigh 10kg of asphalt, 48kg of basalt crushed stone, 28kg of limestone crushed stone, 32kg of granite crushed stone, 15kg of blast furnace slag powder, 5kg of pegmatite mineral powder, 4kg of warm mixing agent, 0.22kg of High-density polyethylene, 0.18kg of recycled high-density polyethylene, 0.2kg of sepiolite fiber and 0.7kg of gypsum fiber. Among them, the mixture of basalt crushed stones, limestone crushed stones and granite crushed stones was sieved together. The pass rate of the sieve with a sieve size of 4.75mm was 32.4%, and the pass rate of a sieve with a sieve size of 9.5mm was 62.3%. The pass rate of the sieve with a hole size of 13.2 mm was 80.7%, and the pass rate of a sieve with a sieve size of 19 mm was 100%. Preheat basalt crushed stone, limestone crushed ston...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com