Method for preparing fresh aromatic essential oil

A technology of aromatic plants and essential oils, applied in the direction of essential oils/fragrances, fat production, etc., can solve a large number of problems that cannot be overcome, and achieve the effects of short processing time, avoiding high temperature, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

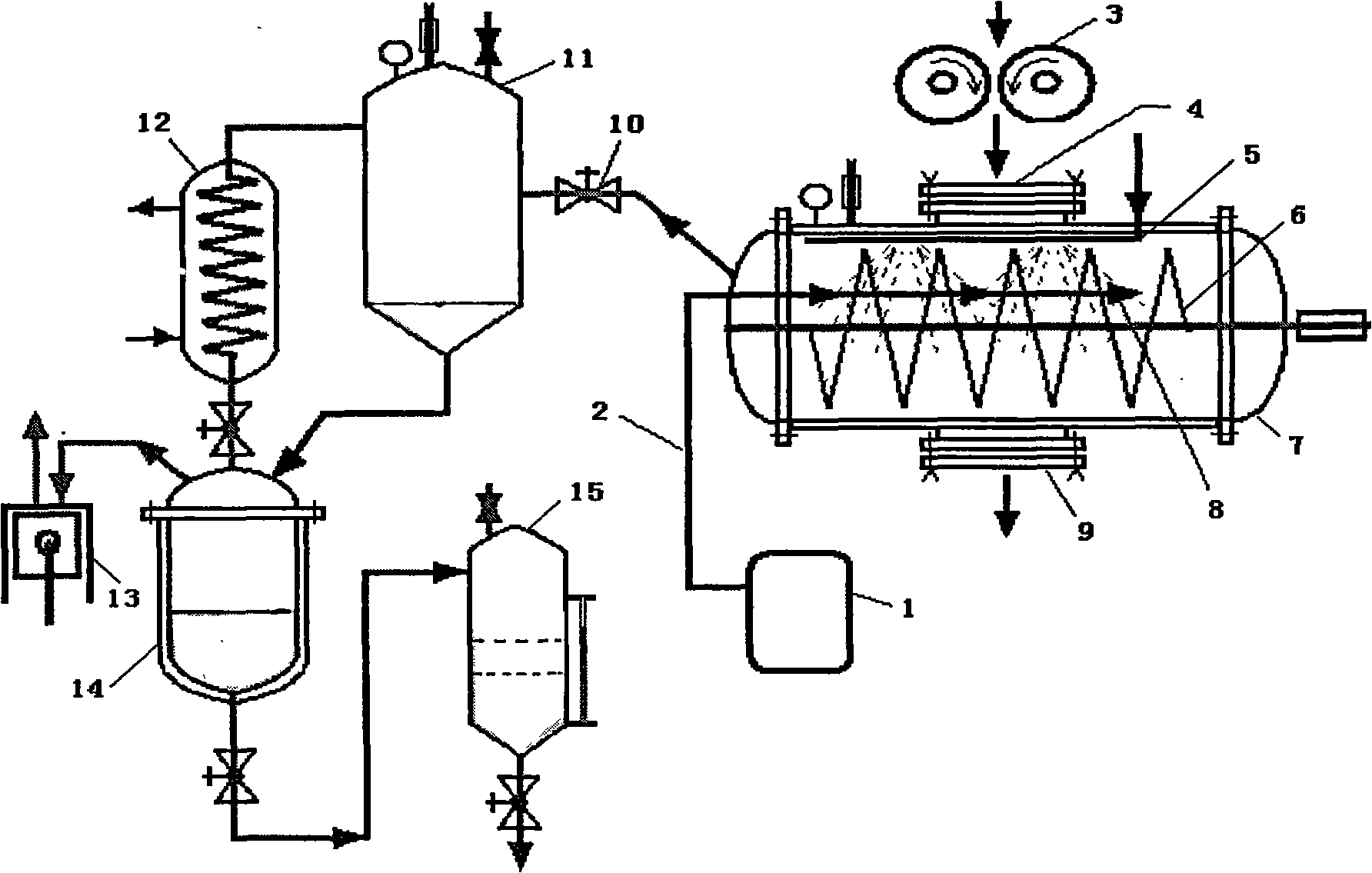

[0041] The fresh rose raw material is sent into the sealed microwave extraction tank through the feed inlet (4) on the top of the microwave extraction tank (7) with 1 microwave hole on one side, and the loading is 90% of the volume of the microwave extraction tank ( In terms of volume), open the agitator (6) of the ribbon type double ribbon structure in the tank to make the material evenly dispersed in the tank, and close the feed inlet (4);

[0042] Vacuum buffer tank (11) and microwave extraction tank (7) equal volume, close the connecting valve (10) of microwave extraction tank and vacuum buffer tank, open vacuum pump (13) and make the pressure of vacuum buffer tank (11) reach 10kPa:

[0043] Turn on the stirrer (6) and the microwave generator (1), heat the rose evenly and rapidly to 100°C, then turn on the electromagnetic valve (10) connecting the microwave extraction tank (7) and the vacuum buffer tank (11), The pressure in the microwave heating tank is quickly reduced to...

Embodiment 2

[0048] Fresh evening primrose flowers are sent into the sealed microwave extraction tank (7) through the feed port (4) on the top of the microwave extraction tank (7) with 4 holes arranged on both sides, and the loading capacity is the microwave extraction tank (7 ) of 80% (by volume), open the agitator (6) with three ribbon structures in the tank to make the material evenly dispersed in the tank, and close the feed port (4);

[0049] Vacuum buffer tank (11) is 2 times of microwave extraction tank (7) volume, closes the connecting valve electromagnetic valve (10) of microwave extraction tank (7) and vacuum buffer tank (11), opens vacuum pump (13) to make vacuum buffer tank (11) the pressure reaches 20kPa;

[0050] Turn on the agitator (6) and the microwave generator (1) in the tank to heat the evening primrose flowers to 90°C evenly and rapidly, and open the connecting valve between the microwave extraction tank (7) and the vacuum buffer tank (11) to make the microwave heating...

Embodiment 3

[0055] a, the fresh lavender flower spikes are crushed and crushed by a double-roller crusher (3) with fine teeth, so that the cells and tissue structure of the flowers are destroyed, and 6 holes are arranged on one side of the broken fresh lavender flower spikes The feed inlet (4) on the top of the microwave extraction tank (7) is sent in the sealed microwave extraction tank (7), and the charge is 70% (by volume) of the microwave extraction tank (7), and the tank inner frame is opened The type agitator (6) makes the material evenly dispersed in the tank, and closes the feed port (4);

[0056] b, the vacuum buffer tank (11) is 2 times the volume of the microwave extraction tank (7), close the connection valve electromagnetic valve (10) of the microwave extraction tank (7) and the vacuum buffer tank (11), open the vacuum pump (13) to make the vacuum The pressure of buffer tank (11) reaches 30kPa;

[0057] c, open the agitator (6) and the microwave generator (1) in the tank, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com