Herbicidal combination for cotton crops

A herbicidal composition and a technology for the composition are applied in the field of herbicidal compositions for cotton crops, and can solve the problems of effectively preventing and controlling broad-leaved weeds in cotton fields without registration, and achieve a good control effect and the effect of expanding the herbicidal spectrum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

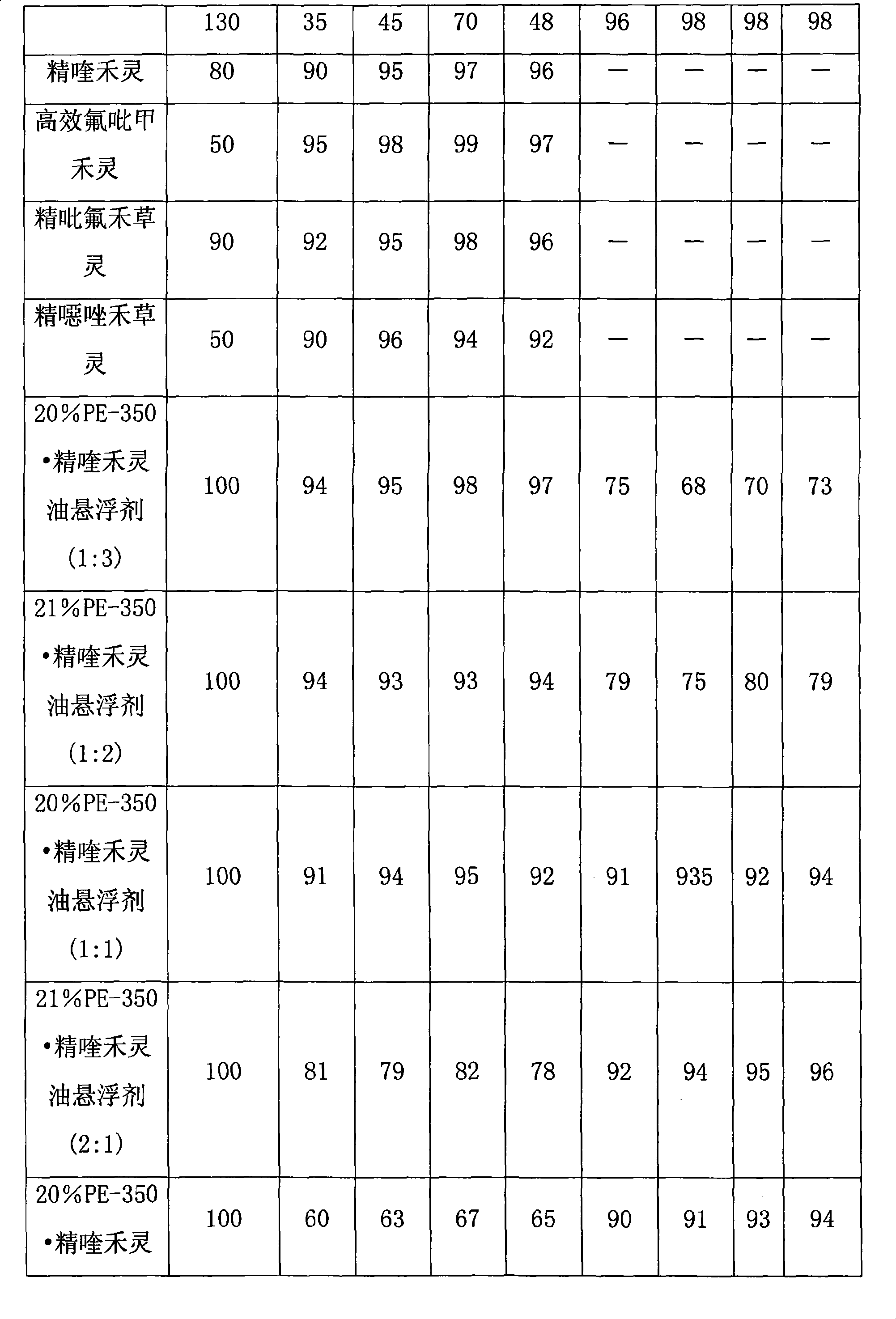

[0025] Example 1: 20% PE-350 quizalofop-p-ethyl oil suspension concentrate (1:1)

[0026] Raw material dosage (weight%)

[0027] PE-350 10

[0028] Quizalofop-ethyl 10

[0029] Farm Milk 100 # 3

[0030] DBS-Ca2

[0031] Arnox BP Series 1

[0033] Ethylene glycol 5

[0034] Silicone 3

[0035] Toluene balance

[0036] According to the above formula, first weigh the active ingredients PE-350, quizalofop-p-ethyl, Arnox BP series, and toluene, transfer them all into a sand mill, and then add 1 part of agricultural milk 100 # , 1 part of DBS-Ca, after being ground to a certain fineness in a sand mill (the fineness should reach 98% or more of particles passing through the 0.043mm sieve), the material is transported to the storage tank, and transferred to the homogenizer after metering. Homogeneous mixer, and then add the remaining additives, after being uniformly dispersed in the homomixer, the product can be prepared.

Embodiment 2

[0037] Example 2: 21% PE-350 quizalofop-p-ethyl oil suspension concentrate (1:2)

[0038] Raw material dosage (weight%)

[0039] PE-350 7

[0040]Quizalofop-ethyl 14

[0041] Farm milk 500 # 2

[0042] Farm milk 600 # 2

[0043] Propylene Glycol 4

[0044] Fatty acid polyoxyalkylene ester 3

[0045] ATMOS300 2

[0046] Xylene balance

[0047] According to the above formula, first weigh the active ingredients PE-350, quizalofop-p-ethyl, ATMOS300, and xylene, transfer them all into a sand mill, and then add 1 part of agricultural milk 500 # , 1 serving of Nongrui 600 # , after being ground to a certain fineness in a sand mill (the fineness should be greater than or equal to 98% of the particles passing through the 0.043mm sieve), the material is transported to the storage tank, and then transferred to the homogeneous mixer after metering. The remaining additives are added, and the product can be prepared after being uniforml...

Embodiment 3

[0048] Example 3: 20% PE-350 Quizalofop-ethyl oil suspension concentrate (1:3)

[0049] Raw material dosage (weight%)

[0050] PE-350 5

[0051] Quizalofop-ethyl 15

[0052] Farm milk 700 # 3

[0053] OP-10 2

[0054] Glycerin 4

[0055] Phosphate 5

[0056] Arnox BP Series 3

[0057] Acetone Balance

[0058] According to the above formula, first weigh the active ingredients PE-350, quizalofop-p-ethyl, Arnox BP series, and acetone, transfer them all into a sand mill, and then add 1 part of Nongru 700 # , 1 part of OP-10, after being ground in a sand mill to a certain fineness (the fineness should be greater than or equal to 98% of the particles passing through the 0.043mm sieve), the material is transported to the storage tank, and transferred to the uniform Homogeneous mixer, and then add the remaining additives, after being uniformly dispersed in the homomixer, the product can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com