Regeneration method of active carbon absorbent

A technology of activated carbon adsorption and activated carbon, which is applied in separation methods, filter regeneration, filtration separation, etc., can solve the problems of increased operating cost of activated carbon regeneration, reduced process economy, safety accidents, etc., to reduce steam or nitrogen consumption, easy to control , The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

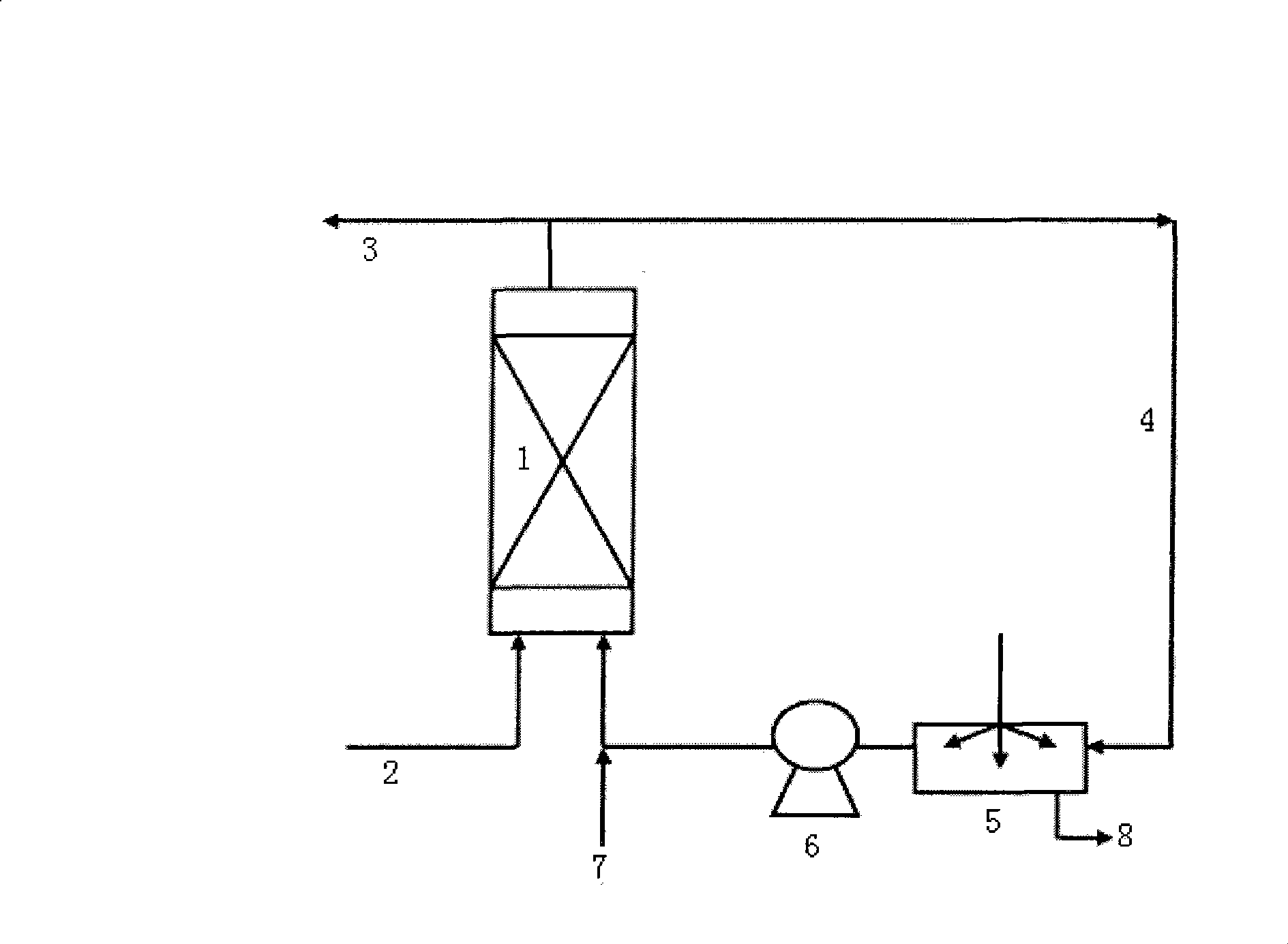

Image

Examples

Embodiment 1

[0018] In a light oil storage tank, the concentration of oil and gas in the exhaust gas is 10% (v) to 45% (v), which is treated with activated carbon adsorption and recovery, and the method of the present invention is used for regeneration after the adsorption is saturated.

[0019] The regeneration process is: use 200°C superheated steam as the regeneration steam, and the volume flow rate of the regeneration steam is 10h -1 After 20 minutes, the regeneration steam is stopped, and the circulation fan is turned on at the same time, and the steam circulation cooling process is carried out. A water purification spraying device is installed on the circulating steam pipeline. After the circulating steam passes through the water purifying spraying device, the temperature drops by 2 to 10°C. After 30 minutes, the temperature of the bed of activated carbon adsorbent drops to 120°C. At this time, the circulating steam is stopped and the The air is further cooled and dried for 20 minute...

Embodiment 2

[0021] Activated carbon adsorption treatment process of certain sulfur-containing (hydrogen sulfide and organic sulfur) and hydrocarbon waste gas, the sulfur content is 5-40mg / m 3 , the hydrocarbon content is 120-900 μL / L, and the activated carbon is regenerated by the method of the present invention after adsorption and saturation.

[0022] The regeneration process is: use 120°C superheated steam as the regeneration steam, and the volume flow rate of the regeneration steam is 20h -1 After 10 minutes, use 250°C steam, and stop the regenerative steam after 30 minutes of steam at 250°C, and turn on the circulation fan at the same time to perform steam circulation cooling treatment. A water purification spray device is installed on the circulating steam pipeline. After the circulating steam passes through the water purification spray device, the temperature drops by 1 to 15°C. The cooling speed is faster first, and then the cooling speed is slower. After 50 minutes, the temperatu...

Embodiment 3

[0024] In the activated carbon adsorption treatment process of certain oily sewage, the sulfur content in the sewage is 2-20 μg / g, the COD (chromium method) is 90-300, and the activated carbon is regenerated by the method of the present invention after the adsorption is saturated.

[0025] The regeneration process is: use 140°C superheated steam as the regeneration steam, and the volume flow rate of the regeneration steam is 30h -1 , Use 350°C steam after 20 minutes, stop the regeneration steam after 50 minutes of steam at 350°C, and turn on the circulation fan at the same time to perform steam circulation cooling treatment. A water purification spray device is installed on the circulating steam pipeline. After the circulating steam passes through the water purification spray device, the temperature drops by 2-40°C. The cooling speed is faster first, and then the cooling speed is slower. After 40 minutes, the temperature of the activated carbon adsorbent bed layer drops To 130...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com