Heating system for engine oil

A heating system and engine technology, which is applied in the direction of engine lubrication, engine components, combustion engines, etc., can solve the problems of engine oil emulsification, etc., and achieve the effect of preventing the service life of engine oil, realizing utilization, and small modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

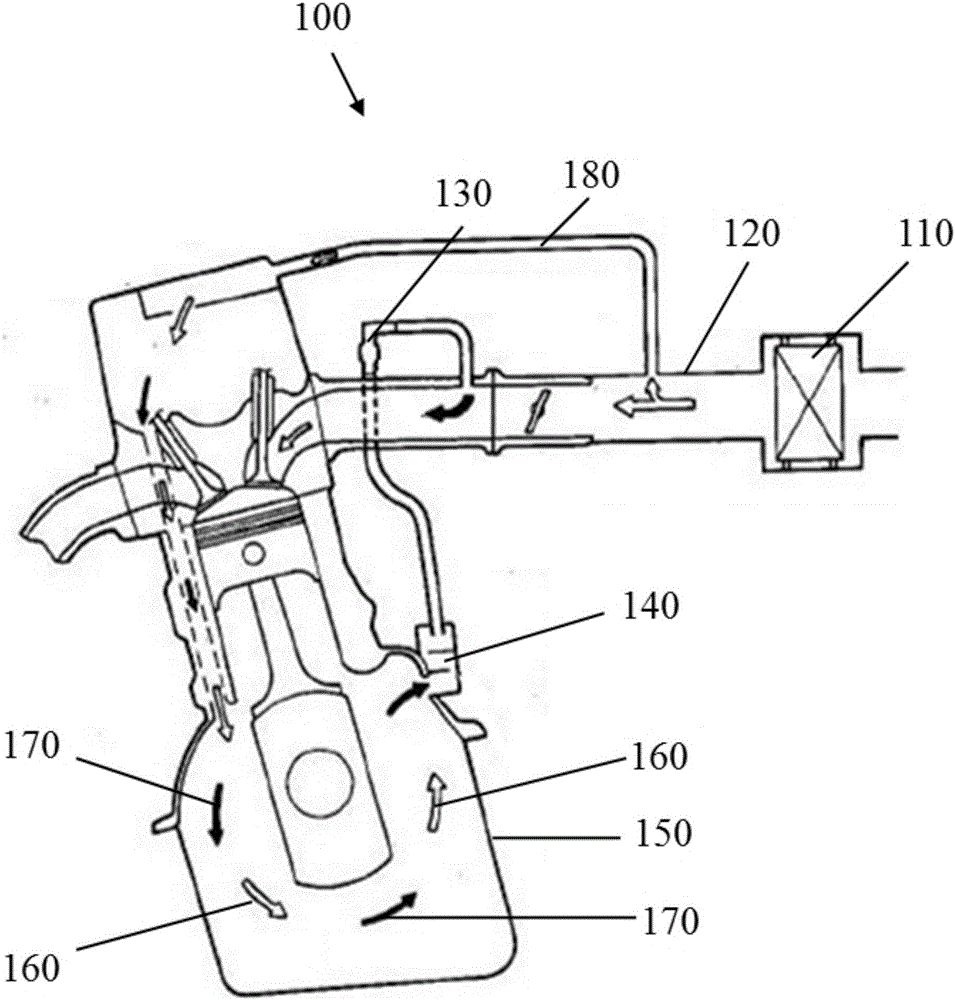

[0049] figure 1 is a schematic block diagram of a prior art crankcase ventilation system 100 showing the flow paths of blow-by gas 170 and fresh air 160, figure 1 , the black solid arrows indicate the flow direction of the blow-by gas 170 , and the hollow arrows indicate the flow direction of the fresh air 160 . Such as figure 1As shown, the crankcase ventilation system 100 is a typical structure of a non-supercharger, and the crankcase ventilation system 100 in the present invention is not limited to this structure. The crankcase ventilation system 100 may generally include a crankcase 150 , an oil separator 140 , a PVC valve 130 , a breather hose 180 and an oil pan 190 . The reason for designing the crankcase ventilation system 100 is as follows: when the engine 320 is running, gas enters the crankcase 150 through the gaps between the cylinder wall, the piston and the piston ring, and the opening of the piston ring. This situation is generally called blow-by. 170 (Blowby)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com