Floating type reverse extrusion forming die

A floating, die set technology, applied in metal extrusion dies and other directions, can solve the problems of difficulty in forming small-diameter thick-walled pipes, cannot be used in mass production, and continuous working time is not long, so as to reduce the dead zone of metal flow. , save material, ensure the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

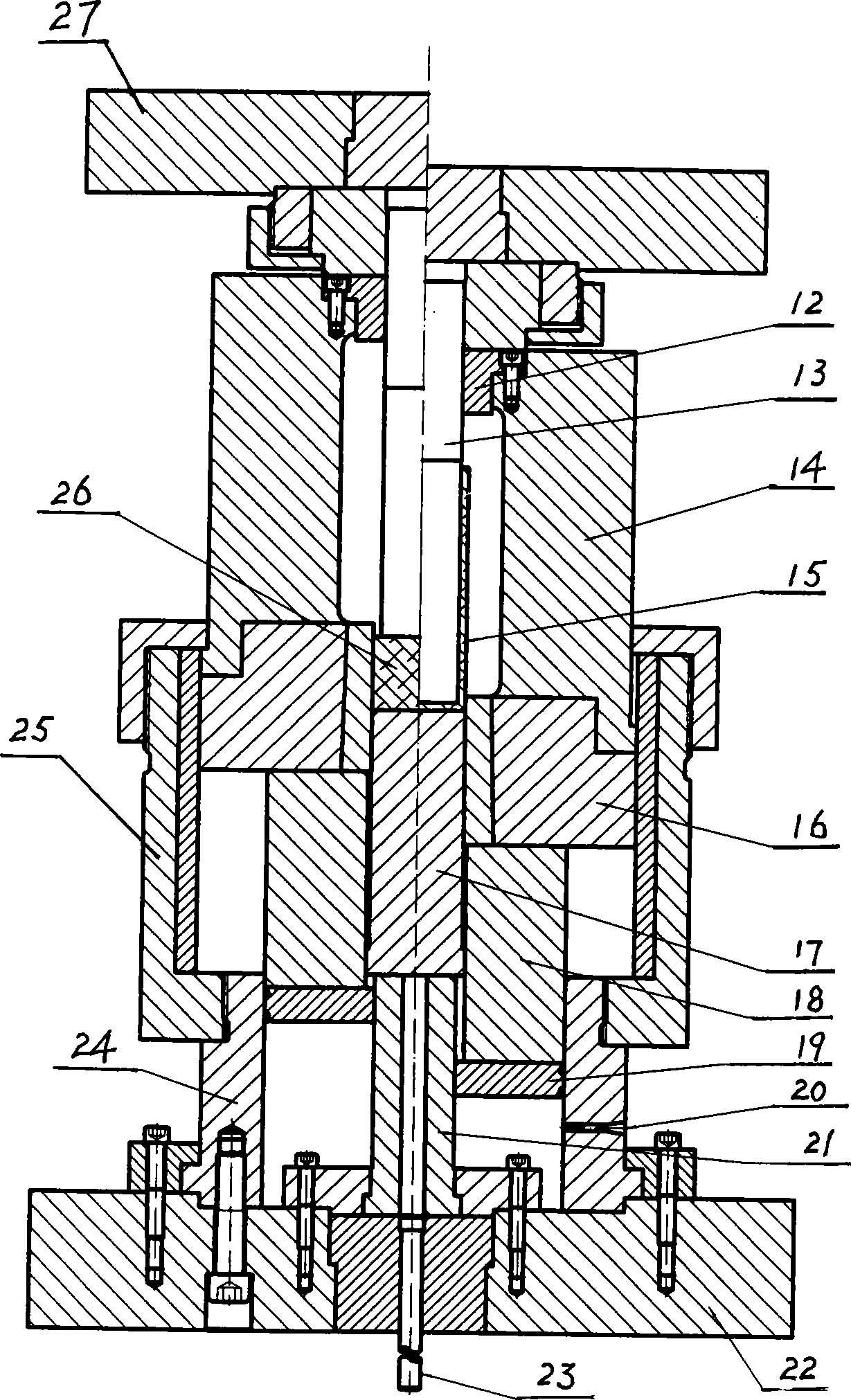

[0025] Such as image 3 As shown, it is a structural schematic diagram of a floating reverse extrusion forming mold base. The floating reverse extrusion forming mold base is composed of a floating guide sleeve 12, a floating guide sleeve frame 14, a floating die 16, a forming pad 17, and a floating die pad Block 18, floating cylinder piston 19, air inlet 20, fixed annular pad 21, lower module 22, ejector rod 23, floating cylinder body 24, outer mold 25 and upper mold frame 27 form.

[0026] The floating cylinder block 24 is fixed with the lower module 22 by screws, the fixed ring pad 21 is installed in the center of the floating cylinder block 24, and its lower part is fixed with the lower module 22 by screws, and the floating cylinder piston 19 is installed outside the fixed ring pad 21, forming Pad block 17 is installed on the upper end of fixed annular pad block 21, floating die pad block 18 is arranged on the upper end of floating cylinder piston 19, floating die pad 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com