Bloom continuous-casting dynamic gentle pressure amount control method-

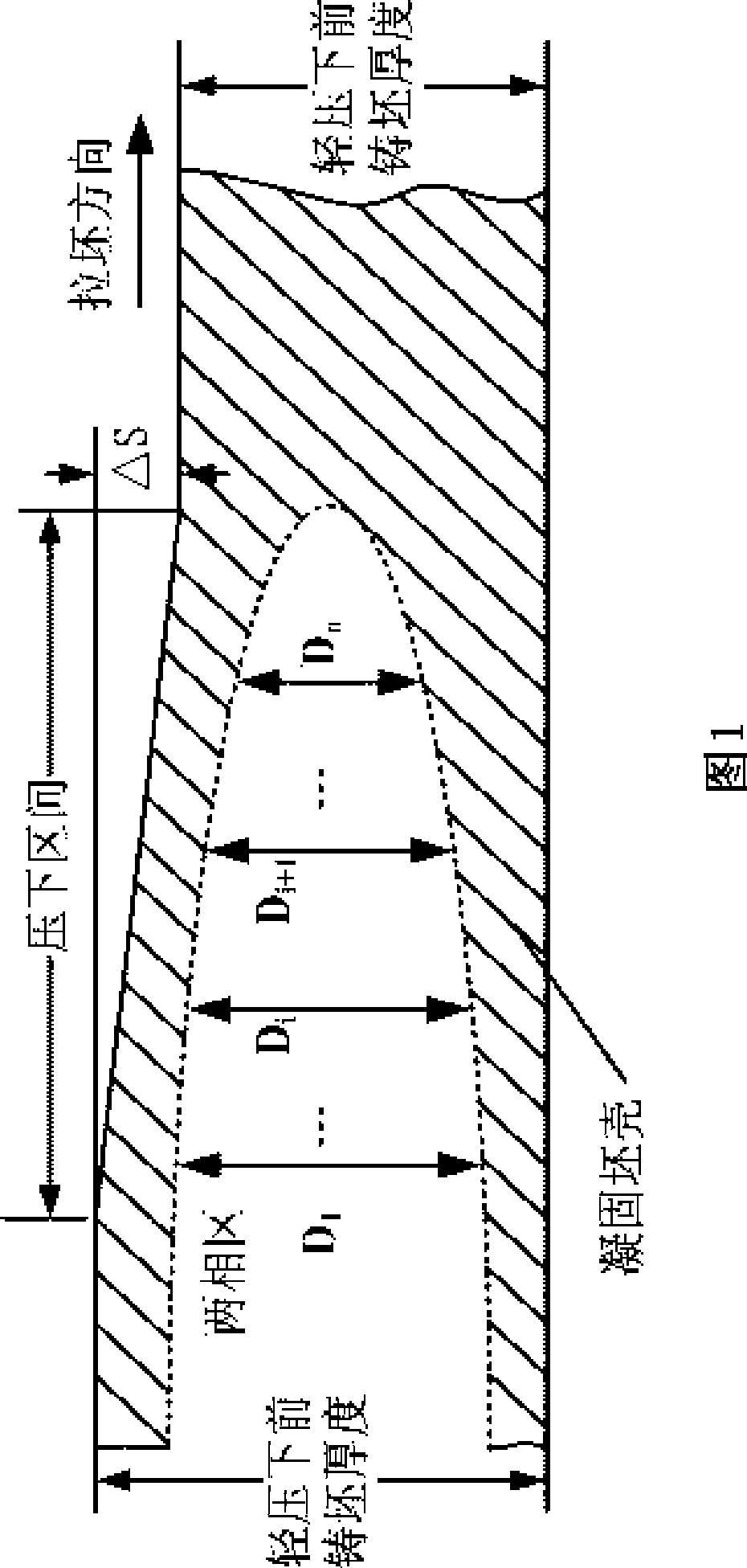

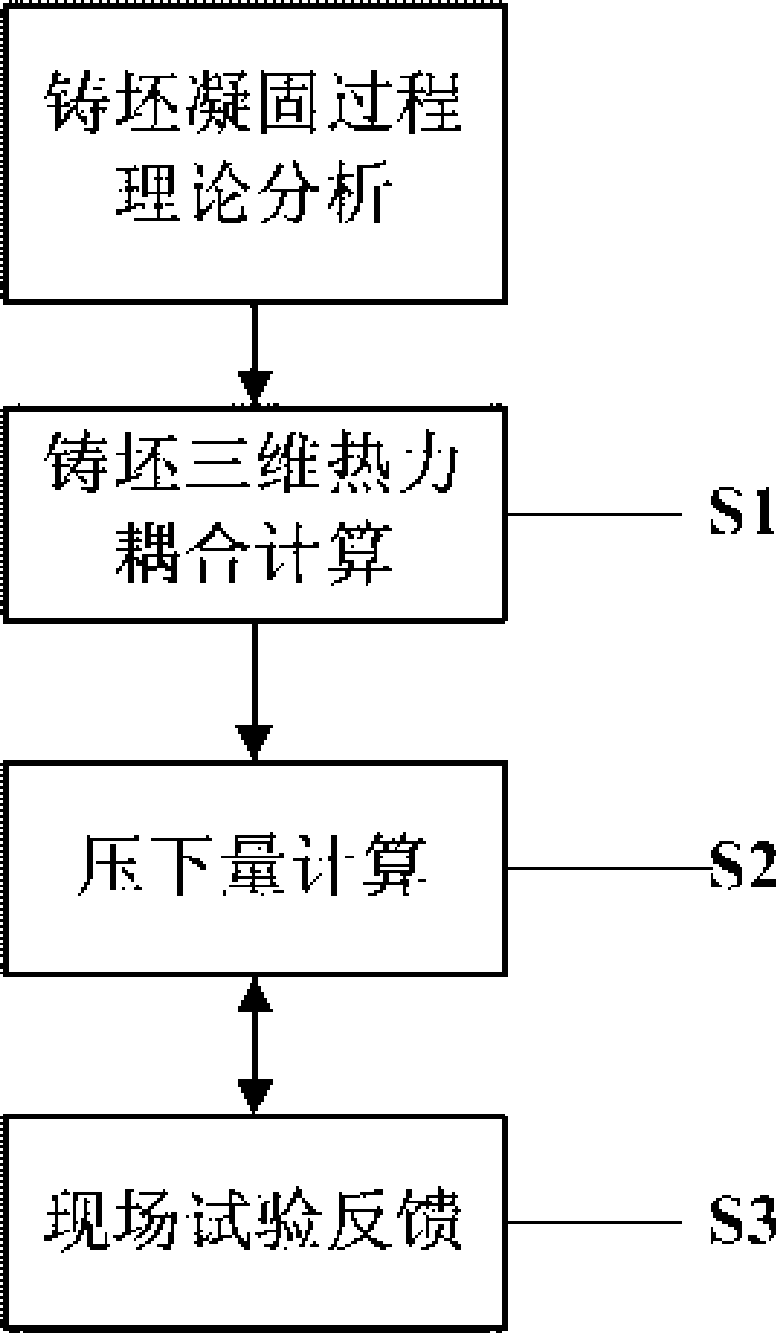

A control method and reduction technology, applied in the field of bloom continuous casting light reduction process, can solve the problems of reduced welding performance, reduced drawing performance, looseness, etc., and achieve the effect of reducing center segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

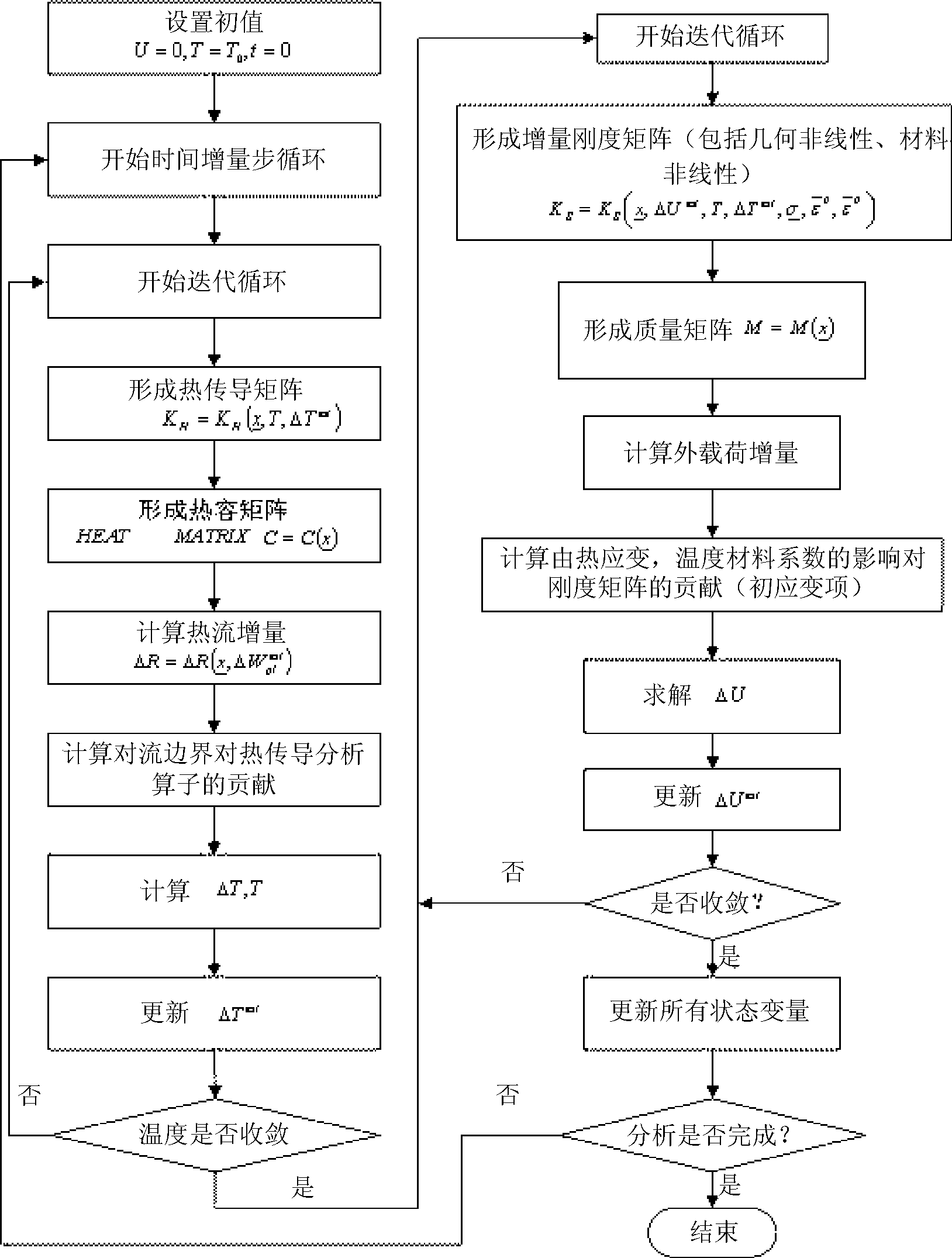

Method used

Image

Examples

Embodiment ( 1

[0080] (1) Casting machine equipment parameters: full arc bloom continuous casting machine, radius 15m, diameter of casting rolls in arc section 220mm, center distance between adjacent casting rolls 210mm, diameter of casting rolls in straightening section and horizontal section 450mm, adjacent casting rolls Roll center spacing 1500mm.

[0081] (2) The slab size is 360mm×450mm, the steel grade is YQ450NQR1, the continuous casting speed is 0.50m / min, the superheat degree is 20~35℃, the continuous casting cooling strength is 0.332L / kg, and the steel grade composition is shown in Table 1.

[0082] Table 1

[0083] C Si Mn P S 0.11~0.14 0.30~0.50 1.25~1.40 0.008~0.022 0.005~0.015

[0084] (3) In the two-phase region at the end of solidification, light reduction is performed within the solid phase ratio fs=0.5-0.7, the reduction amount is 4.50 mm, and the set value of each pair of reduction rollers is shown in Table 2.

[0085] ...

Embodiment ( 2

[0089] (1) The parameters of the casting machine equipment are as in Example (1).

[0090] (2) The slab size is 360mm×450mm, and the steel grade is 45 # , the continuous casting speed is 0.65m / min, the superheat degree is 20~35℃, the continuous casting cooling strength is 0.369L / kg, and the steel grade composition is shown in Table 3.

[0091] table 3

[0092] C Si Mn P S 0.42~0.50 0.17~0.37 0.50~0.80 0.010~0.025 0.008~0.020

[0093] (3) In the two-phase zone at the end of solidification, light reduction is performed within the fs=solid phase ratio of 0.5 to 0.8, and the reduction amount is 6.40 mm. The setting values of each pair of reduction rollers are shown in Table 4.

[0094] Table 4

[0095] Gently press down on the rack number 1 # 2 # 3 # 4 # 5 # 6 # 7 # Set value of pressing amount / mm 0 1.85 2.02 1.44 1.09 0 0

[0096] (4) The central segregation rating of th...

Embodiment ( 3

[0098] (1) The parameters of the casting machine equipment are as in Example (1).

[0099] (2) The slab size is 360mm×450mm, the steel grade is 20(C), the continuous casting speed is 0.80m / min, the superheat degree is 20~35℃, the continuous casting cooling strength is 0.416L / kg, and the steel grade composition is shown in Table 5. .

[0100] table 5

[0101] C Si Mn P S 0.17~0.23 0.17~0.37 0.35—0.65 0.010~0.025 0.008~0.020

[0102] (3) Light reduction is performed within the solid phase ratio of 0.5 to 0.9 in the two-phase zone at the end of solidification, and the reduction amount is 7.72 mm. The setting values of each pair of reduction rollers are shown in Table 6.

[0103] Table 6

[0104] Gently press down on the rack number 1 # 2 # 3 # 4 # 5 # 6 # 7 # Set value of pressing amount / mm 0 1.15 1.36 1.86 1.58 1.04 0.73

[0105] (4) The central segregation rating of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com