Arc source of rotary magnetron arc ion plating

An arc ion plating and rotating magnetic field technology, which is applied in ion implantation plating, sputtering plating, vacuum evaporation plating, etc., can solve the problems of discharge that cannot effectively improve arc spot, poor adjustability, fixed magnetic field potential, etc. Intensity is difficult to adjust and other problems to achieve the effect of improving etching uniformity and target utilization, reducing emission, and achieving diversity

Inactive Publication Date: 2009-02-11

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF2 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method needs to add a complex mechanical control mechanism; at the same time, the position of the magnetic field is fixed and the intensity is difficult to adjust. It is only a mechanical movement that causes the change of the distribution of the magnetic field, and the adjustability is poor, which cannot effectively improve the arc spot. Discharge, suppress the emission of particles; and it involves many problems such as sealing and cooling, so it is difficult to popularize and apply

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

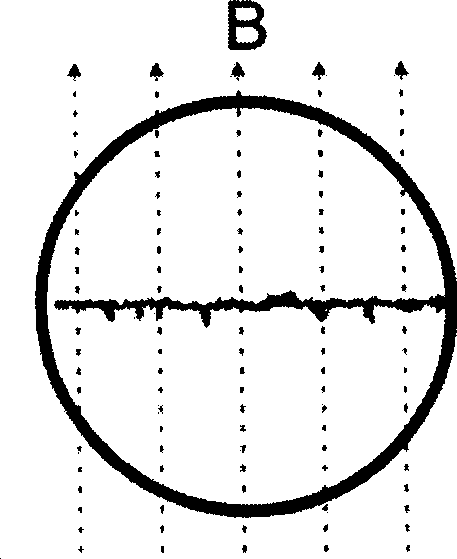

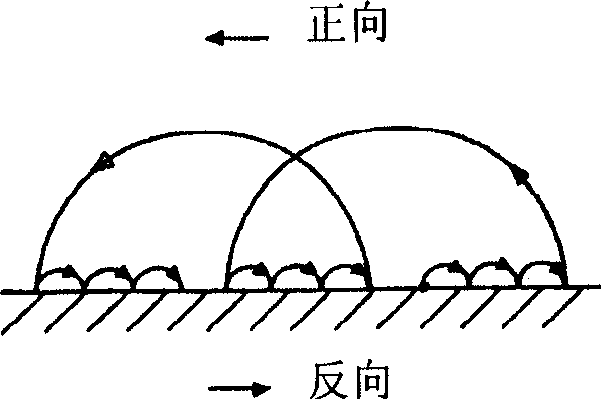

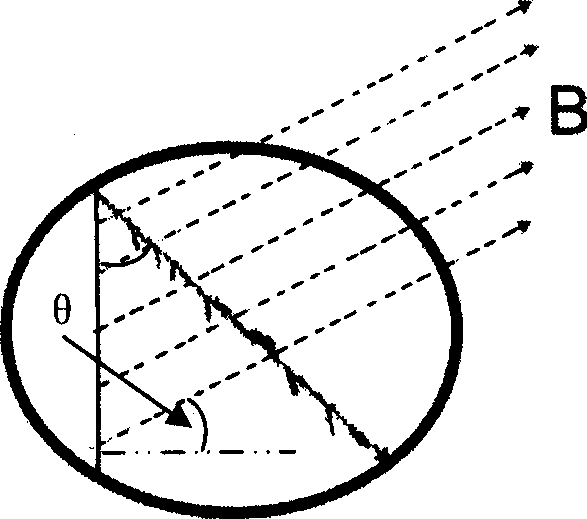

The invention relates to the field of film preparation, in particular to a rotary magnetron arc ion plating arc source which controls the arc point movement by making use of a rotary magnetic field. A rotary magnetic field generating device is arranged in the space around a target material, the rotary magnetic field generating device forms a whole electromagnetic circuit framework by adopting a plurality of magnetic poles which are different from angles differing in a certain angle, connected with each other and are evenly distributed on the same circumference, the amount of the magnetic poles is 4n or 3n, wherein, the n is not less than 1; an excitation coil is sheathed on the magnetic poles or is embedded in a slot between the adjacent magnetic poles, two-phase excitation with the phase difference of 90 degrees or three-phase excitation with the phase difference of 120 degrees is adopted to supply power so as to generate an adjustable rotary magnetic field in a space surrounded by the magnetic poles. By controlling the arc point movement through the rotary magnetic field with adjustable speed and amplitude, the arc source can improve the discharge form and the operating stability of the arc spot, improve the etching uniformity and the utilization rate of the target material and reduce the large particle emission of the target material. The arc source is used for preparing high-quality films and functional films and expanding the application range of the arc ion plating.

Description

technical field The invention relates to the field of thin film preparation, in particular to a rotating magnetron arc ion plating arc source which utilizes a rotating magnetic field to control the movement of the arc spot, which is used to improve the discharge form of the arc spot, control the movement of the arc spot, and improve target etching. Uniformity, reducing or suppressing the emission of large particles of the target to prepare high-quality thin films. Background technique Arc ion plating is one of the most important technologies in industrial coating production and scientific research. Due to its simple structure, high ionization rate (70%-80%), high energy of incident particles, good diffraction, it can realize low temperature deposition, etc. A series of advantages have enabled the arc ion plating technology to develop rapidly and be widely used, showing great economic benefits and industrial application prospects. Arc ion plating is a coating technology bas...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C14/32

Inventor 闻立时郎文昌孙超宫骏赵彦辉肖金泉

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com