Pneumatic air distributing engine

An engine and pneumatic technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of easy formation of vibration lines on the cylinder surface, easy overspeed at no-load, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

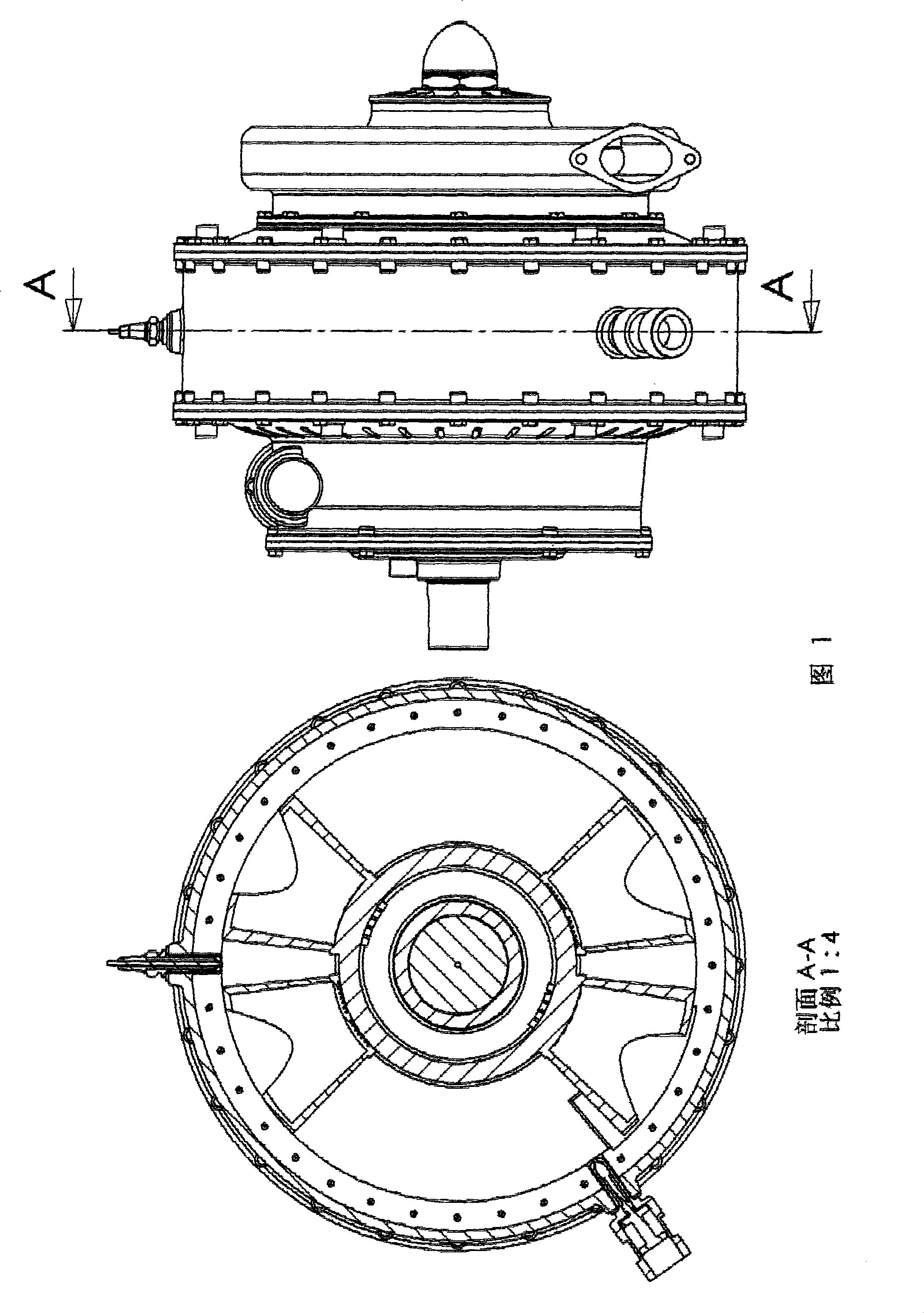

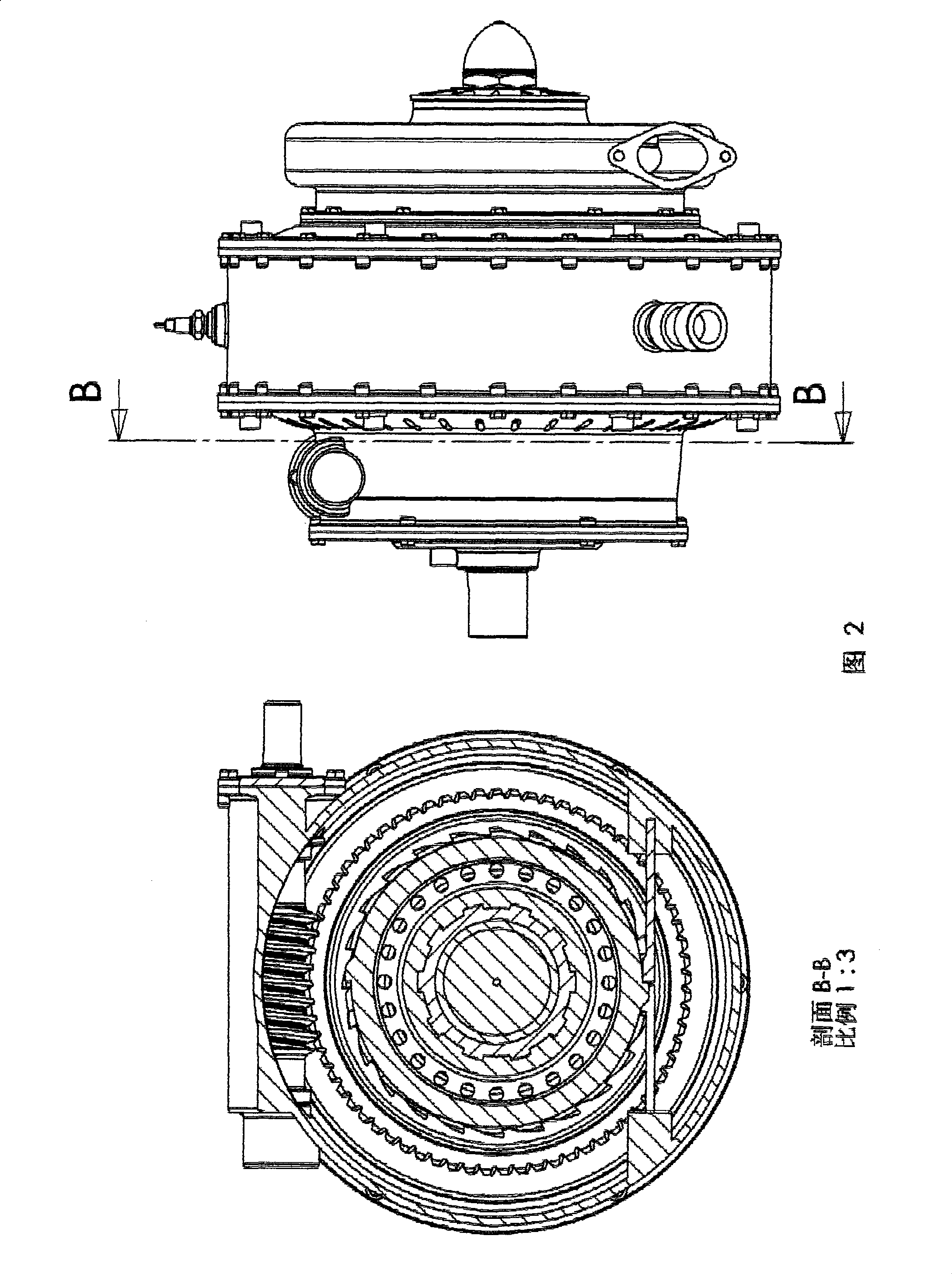

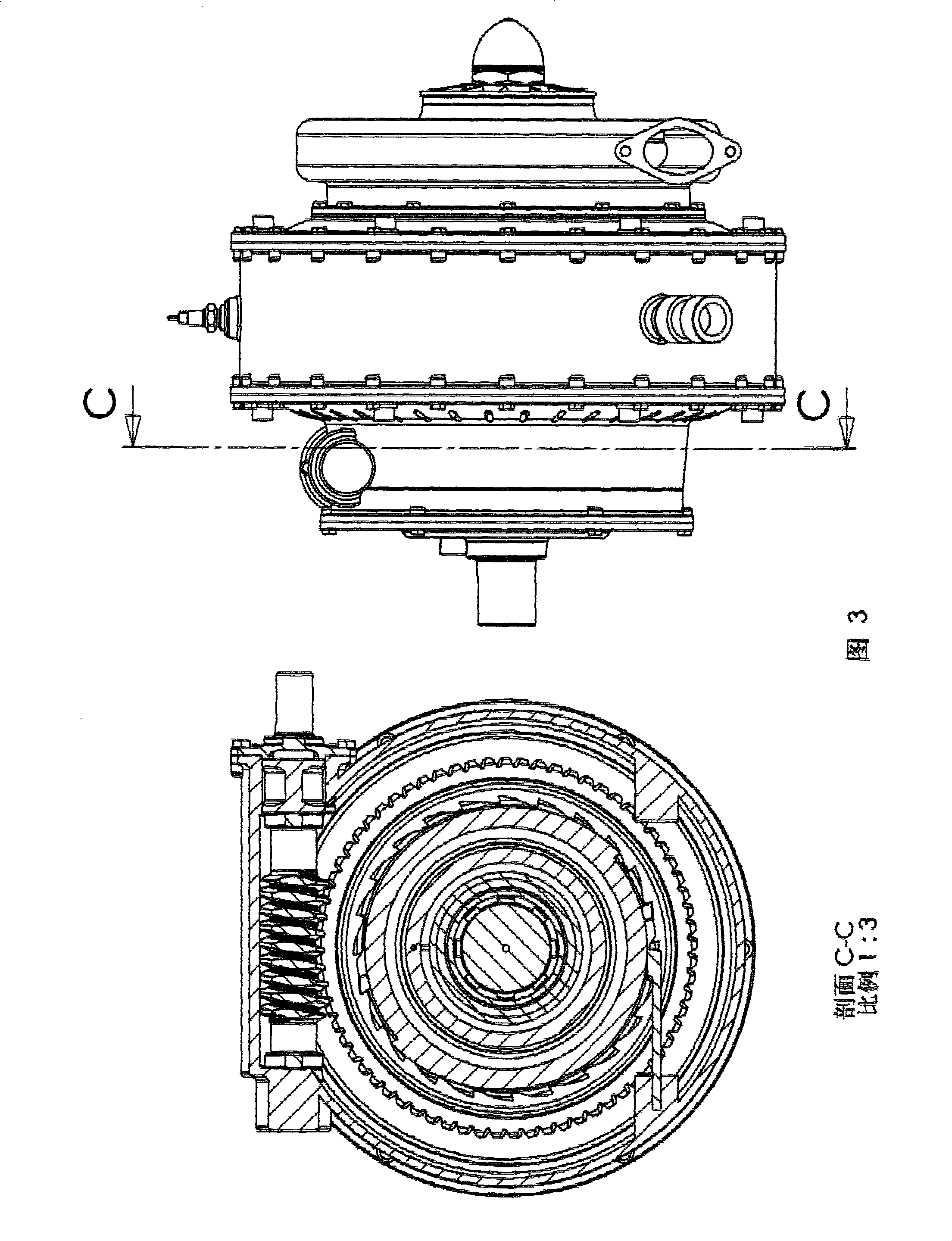

[0065] It can be seen from Figure 2 that the assembly structure of the engine is as follows: the main shaft (1) is engaged with the starting cam (2), the power piston (6) and the centrifugal impeller (9) through splines, and the starting pawl ( 3), the gas distribution spring (5) is installed on the starting cam (2), one end of the gas distribution spring (5) is inserted into the small hole of the spoke plate of the starting cam (2), and the other end is inserted into the non-return ratchet (11) in the small hole of the spoke plate. The power piston (6) is fixed on the main shaft (1) with a nut (7), the centrifugal impeller (9) is fixed on the main shaft (1) with a shaft end nut (10), and the turbine (8) is fixed on the centrifugal impeller (9) with bolts. )superior. Main shaft (1) is supported on end cover (14) and rear casing (21) with bearing (29). The gas distribution piston (13) is supported on the main shaft (1) through sliding bearings, and the non-return ratchet (11)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com