Conductive member, and process cartridge and image forming apparatus

A technology of conductivity and processing box, which is applied in the direction of corona discharge device, electric recording process using charge pattern, equipment for electric recording process using charge pattern, etc. It can solve the problems of reducing yield and not eliminating foreign matter, etc., and achieves Improve the yield, reduce the surface viscosity, and improve the effect of the pass rate of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0180] Embodiments of the present invention will be described in detail below.

[0181]

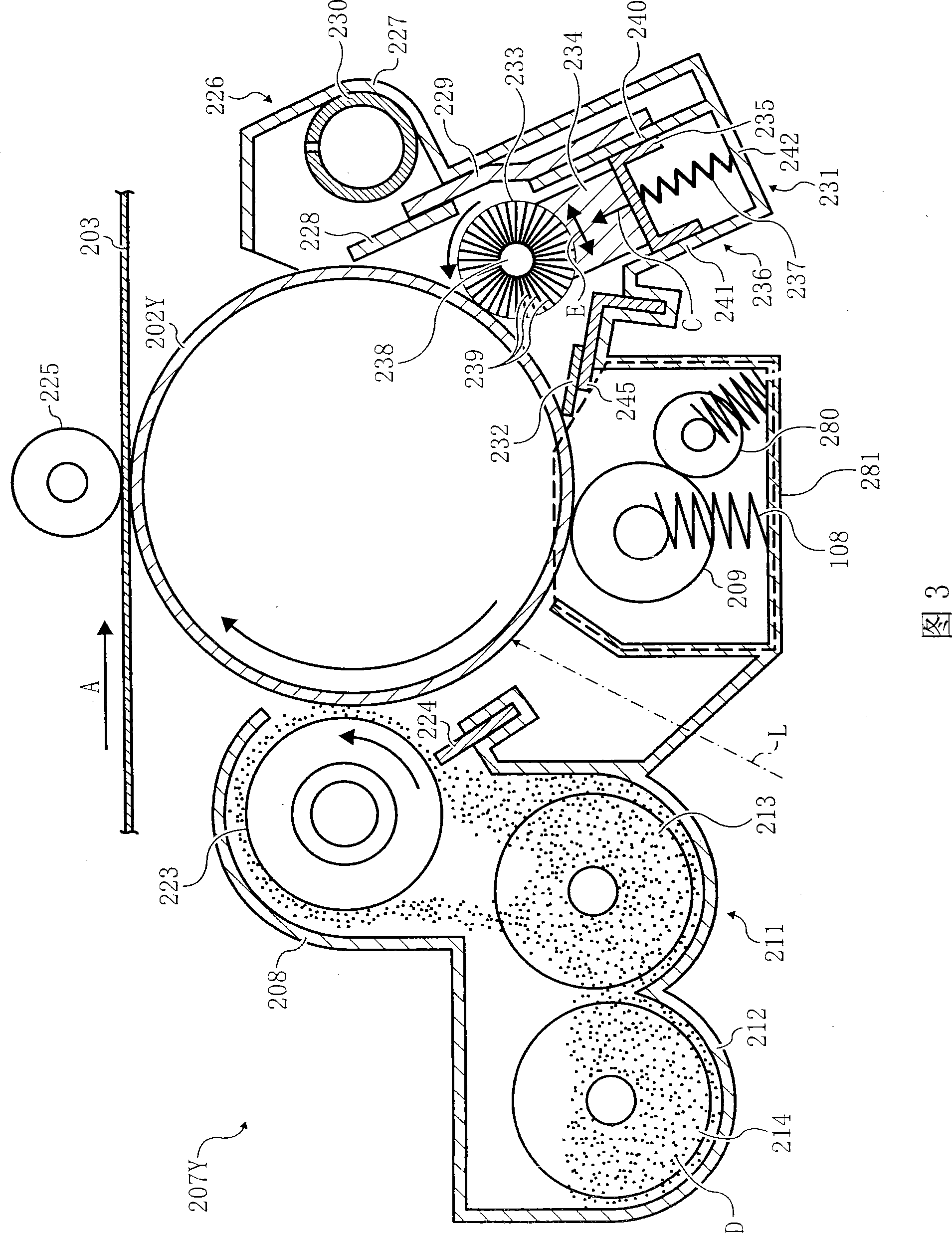

[0182] The conductive support 106 is a nickel-plated stainless steel support. The electrical impedance adjustment layer 104 has a cylindrical shape, is made of a resin composition, and is formed on a support by molding.

[0183] The above resin composition is formed by melt mixing the following materials and ratios: 40% by weight of ABS resin (GR3000, manufactured by Denki Kagaku Kogyo) and 60% by weight of polyether ester amide (IRGASTAT P18, manufactured by CibaSpeciality Chemicals Inc.) to form the base resin, 4 parts by weight of polycarbonate-glycidyl methacrylate-styrene-acrylonitrile polymer (Modiper C L440-G, manufactured by NOF) was added to 100 parts by weight of the base resin.

[0184] Then, after gate cutting and length adjustment are performed on the electrical impedance adjustment layer 104 formed above, the ring-shaped gap maintaining member 103 is pressed into both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com