Non-aqueous electrolyte battery and negative electrode used therein

A non-aqueous electrolyte and battery technology, applied in non-aqueous electrolyte battery electrodes, non-aqueous electrolyte batteries, battery electrodes, etc., can solve problems such as heat accumulation, uneven battery reaction, and difficulty in ensuring battery safety or reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

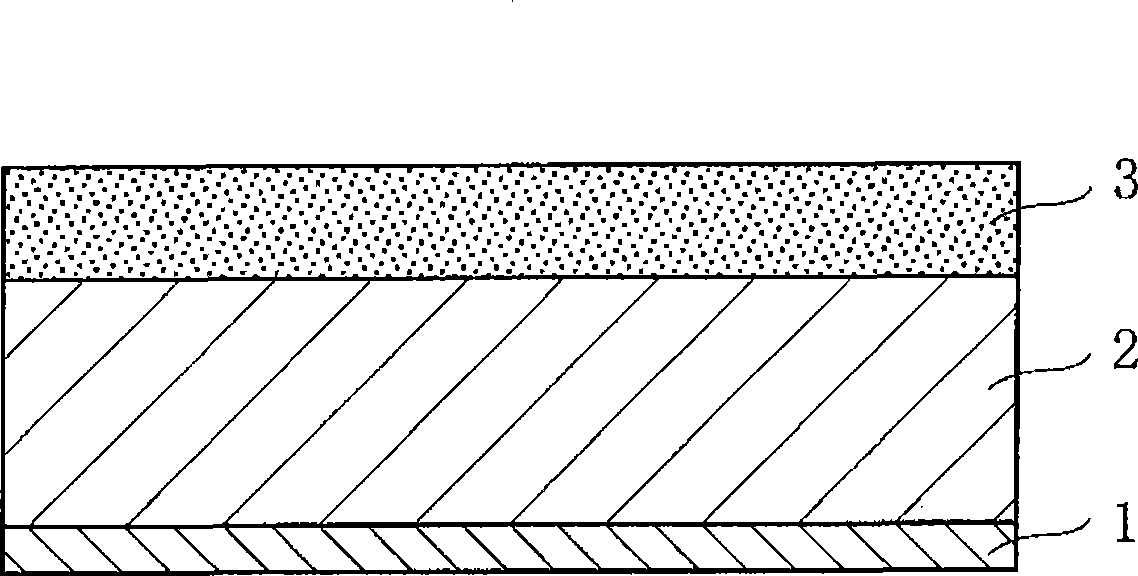

Image

Examples

preparation example Construction

[0062] 〔Preparation of non-aqueous electrolyte solution〕

[0063] In a mixed solvent in which ethylene carbonate (EC) and diethyl carbonate (DEC) are mixed at a ratio of 3:7 by volume, LiPF 6 Prepared by dissolving at a ratio of 1.0 mol / L.

[0064] 〔Battery assembly〕

[0065] Install the lead terminals on the positive and negative electrodes respectively, insert the spacer made of polyethylene, coil it in a spiral shape and apply pressure to manufacture the flattened electrode body, and place it in the storage space of the aluminum laminate film as the battery outer package The electrode body is arranged inside, and after the non-aqueous electrolyte solution is injected into the space, the aluminum laminated films are welded and sealed to each other to manufacture a battery. The design capacity of this battery is 650mAh, and its design capacity is based on the charge termination voltage of 4.2V.

[0066] [Measurement of degree of etherification of CMC]

[0067] The degree ...

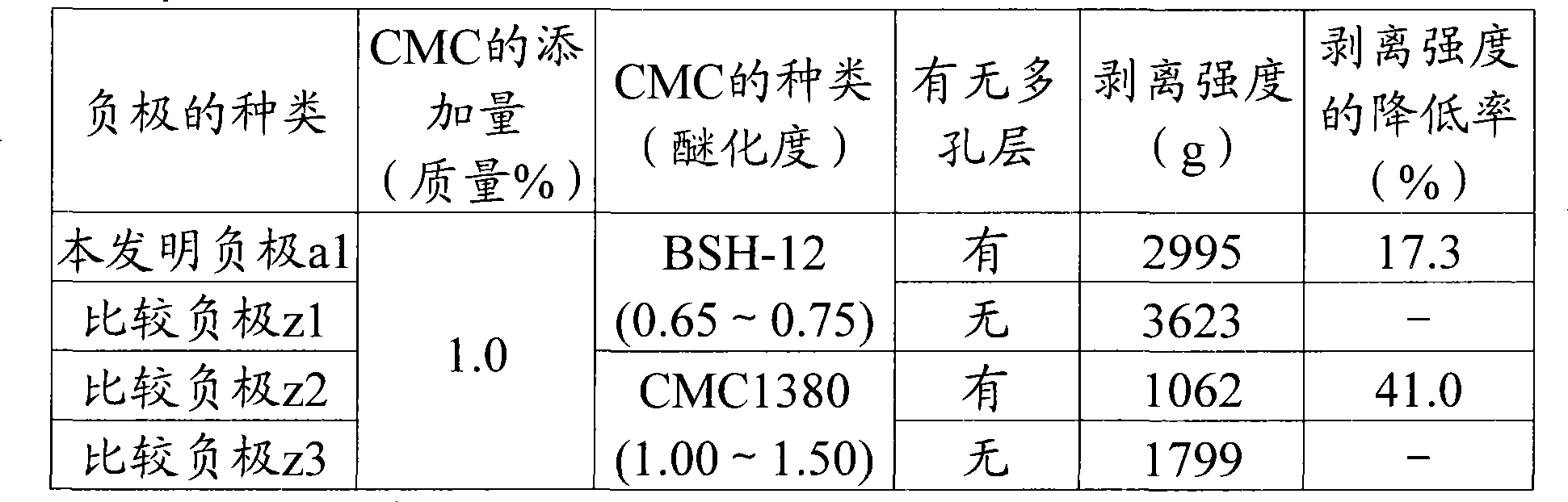

Embodiment 1

[0087] As Example 1, the negative electrode and battery shown in the above-mentioned best mode were used.

[0088] The thus produced negative electrode and battery are hereinafter referred to as negative electrode a1 of the present invention and battery A1 of the present invention, respectively.

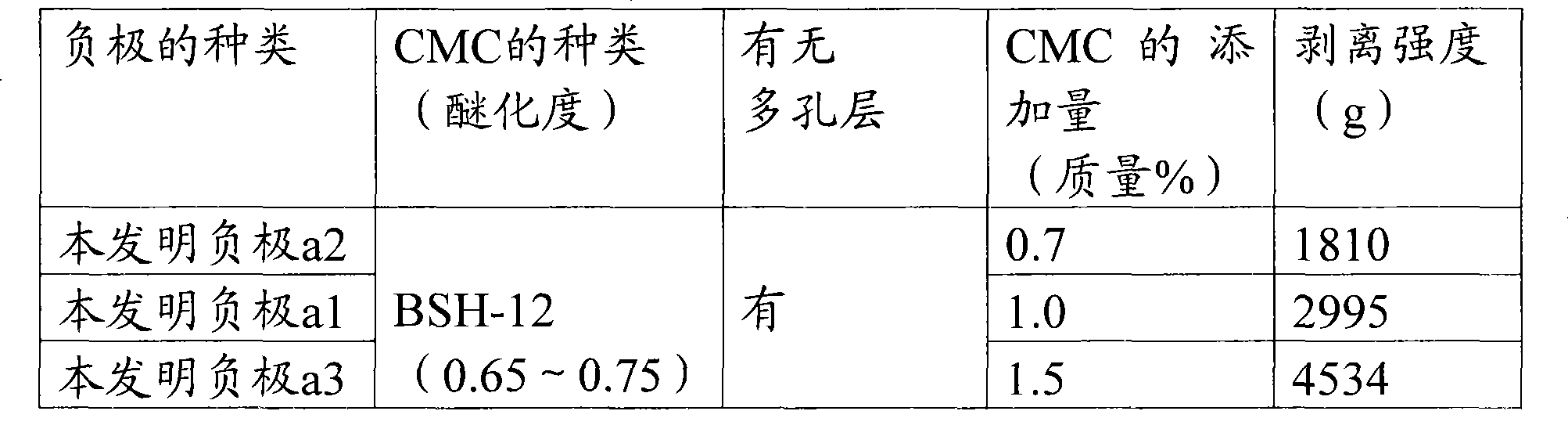

Embodiment 2

[0090] In the manufacture of the negative electrode active material layer, except that the ratio of artificial graphite: CMC: SBR is controlled to be artificial graphite: CMC: SBR=98.3:0.7:1.0, the negative electrode is manufactured in the same way as in Example 1 above.

[0091] The negative electrode thus produced is hereinafter referred to as the negative electrode a2 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Etherification degree | aaaaa | aaaaa |

| Etherification degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com