Device and method for injecting ion on inner surface of hollow cathode coupling positive voltage bias voltage tube

A positive bias tube and hollow cathode technology, applied in the direction of plasma, discharge tube, electrical components, etc., can solve the problems of plasma difficulties, achieve high utilization rate and reduce diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

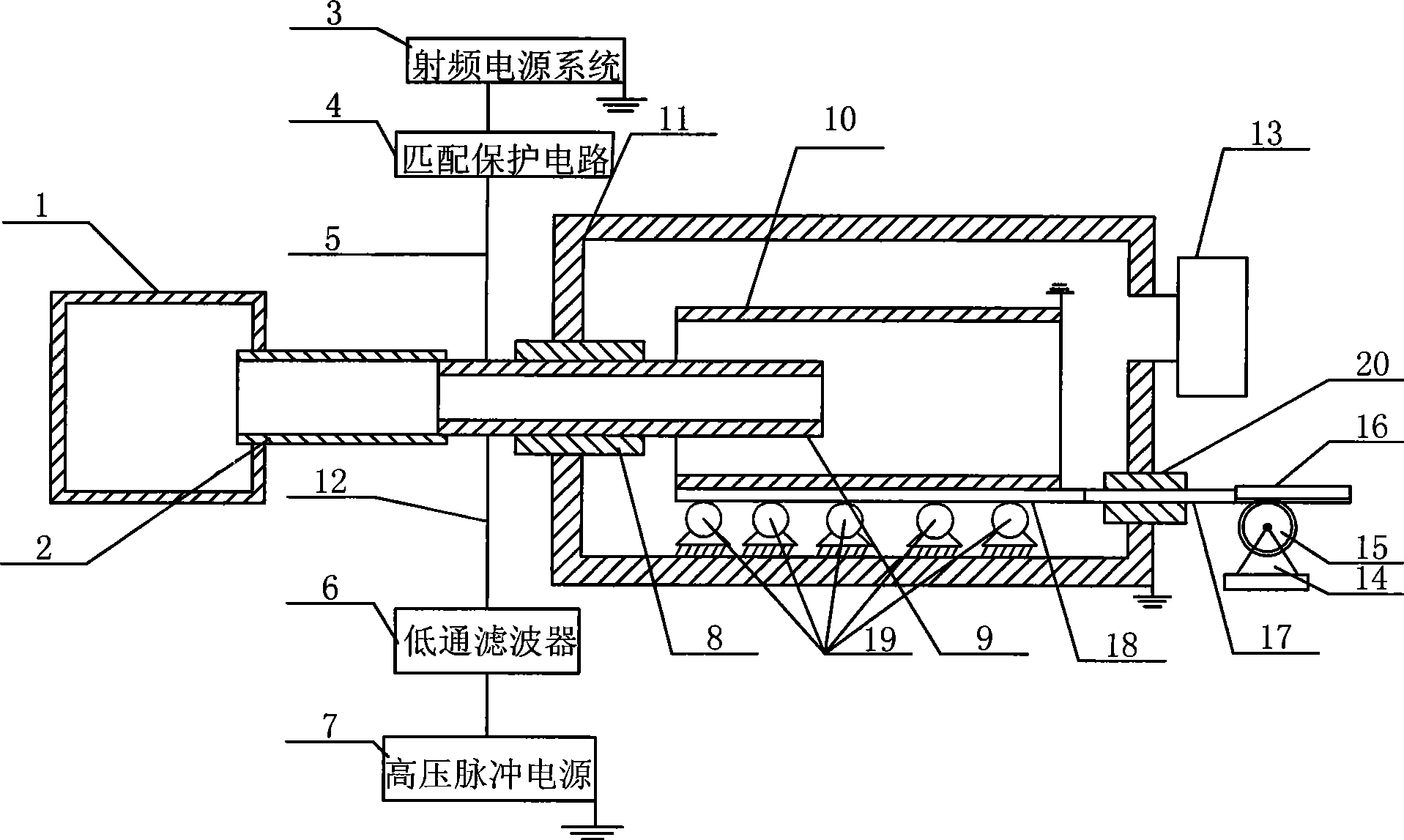

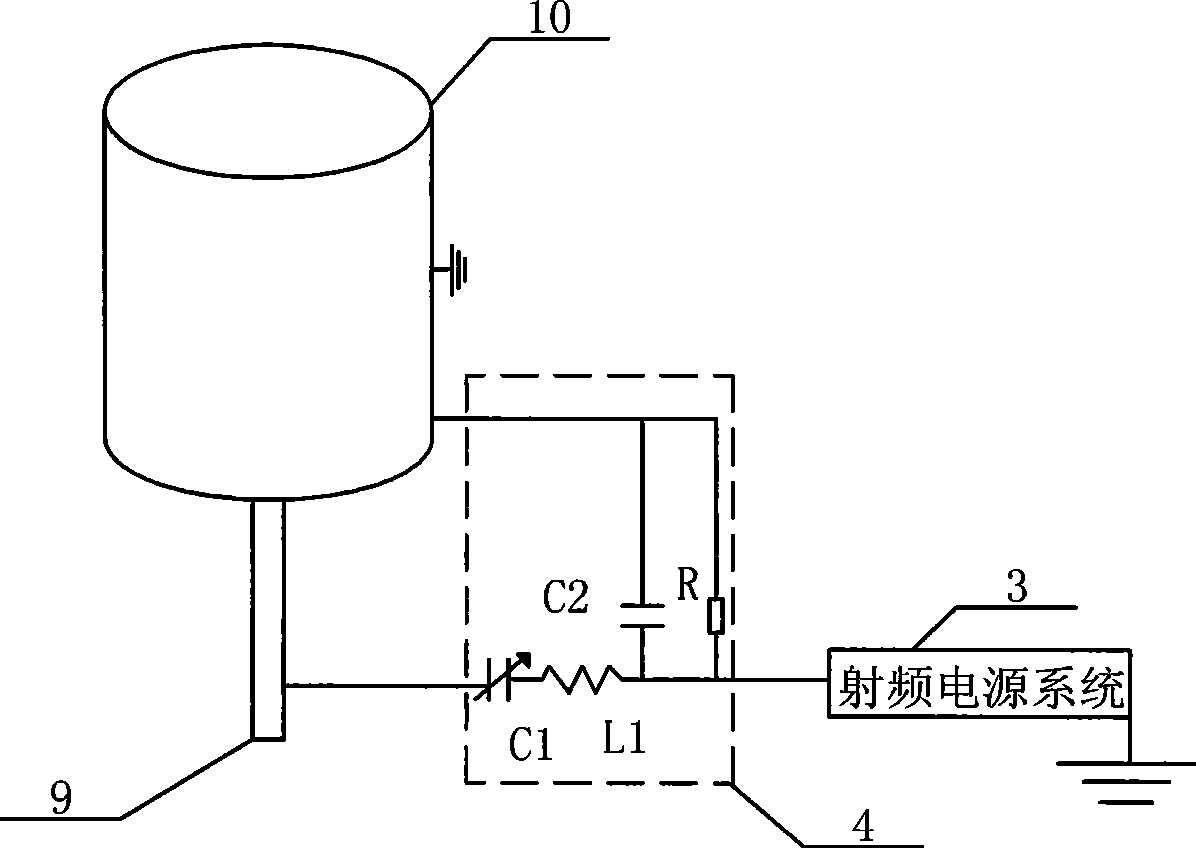

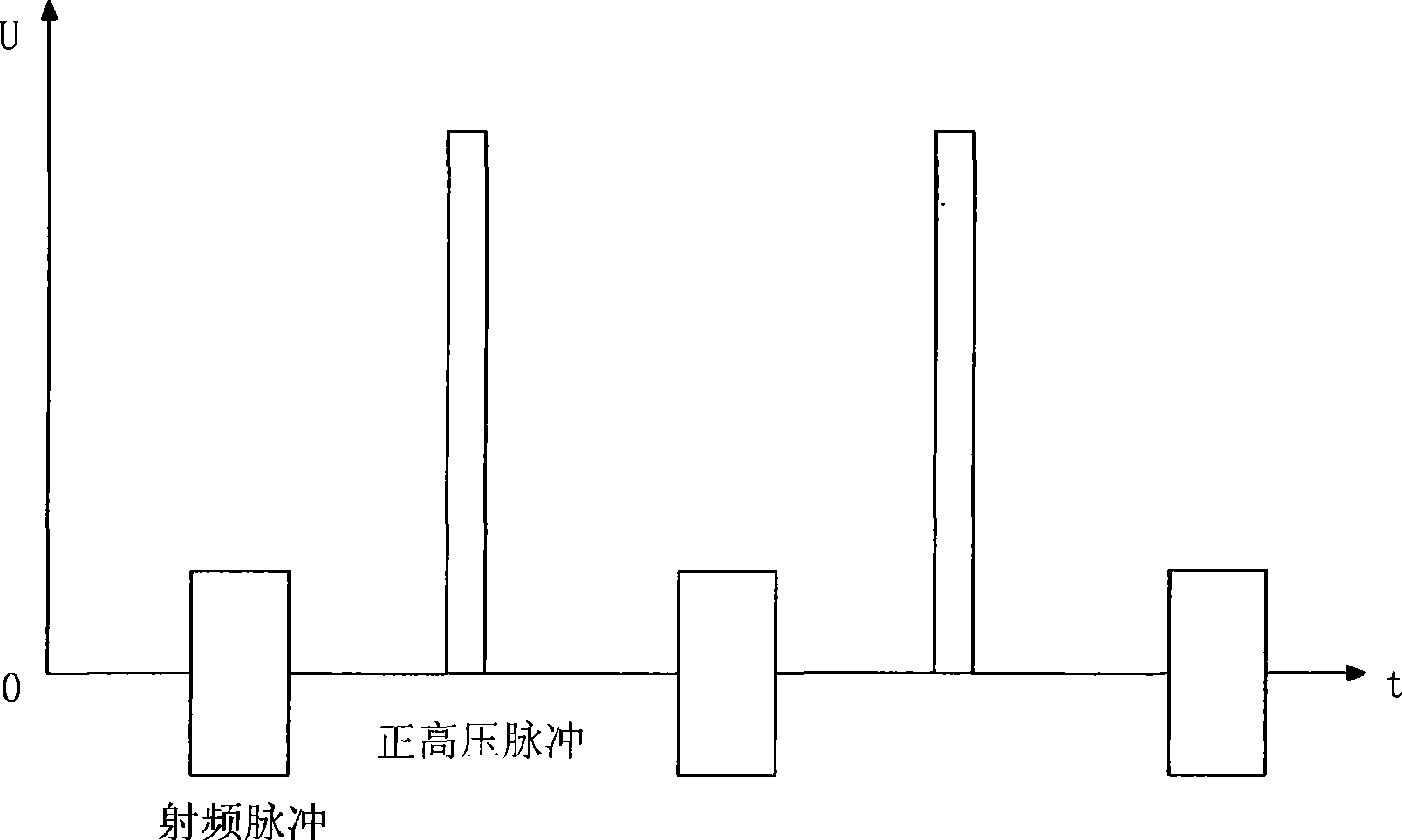

[0009] Specific implementation mode one: combine figure 1 Describe this embodiment, the device for implanting ions on the inner surface of the hollow cathode coupled positive bias tube of this embodiment is composed of a gas source chamber 1, a vacuum chamber 11, an insulating ventilation tube 2, a radio frequency power supply system 3, a matching protection circuit 4, and a cable 5 , a high-voltage cable 12, a low-pass filter 6, a high-voltage pulse power supply 7, an insulator 8, and a hollow cathode tube 9; One end of 9 is set on the central axis in the workpiece tube 10, the other end of the hollow cathode tube 9 passes through the vacuum chamber 11 and is connected to one end of the insulating vent pipe 2, and the other end of the insulating vent pipe 2 is connected to the gas source chamber 1. The output ends are connected, the insulator 8 is set on the hollow cathode tube 9 and fixed in the center hole of the input end face of the vacuum chamber 11, the positive pole of...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 The present embodiment will be described. The inner diameter of the hollow cathode tube 9 in the present embodiment is 0.5-20 mm. When the hollow cathode tube 9 adopts cathode materials such as Cr, Ti or Zr, a pure metal coating can be obtained on the inner surface of the workpiece tube 10 .

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 To describe this embodiment, the connection point where the high voltage cable 12 is connected to the hollow cathode tube 9 in this embodiment is located between the insulating ventilation pipe 2 and the insulator 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com