High-speed punched hole tubular shape electrode

A tubular electrode and high-speed perforation technology, which is applied in electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problems of increased processing cost and high consumption, and achieve the effects of reduced consumption, fast processing speed and good surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

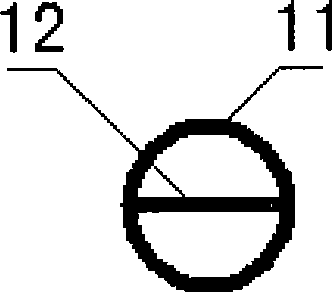

[0020] A high-speed perforated tubular electrode with a cross-sectional shape such as image 3 As shown, an outer tube 11 is included, and an inner core 12 is arranged axially inside the outer tube 11 .

[0021] And the inner core 12 and the outer tube 11 are fixed as an integral structure.

[0022] And the inner core 12 runs through the center of the outer tube 11 .

[0023] The inner core 12 is a rectangular structure passing through the diameter of the outer tube 11 . The inner core 12 divides the outer tube 11 into two semicircular shapes.

Embodiment 2

[0025] A high-speed perforated tubular electrode with a cross-sectional shape such as Figure 4 As shown, an outer tube 11 is included, and an inner core 13 is arranged in the axial direction of the outer tube 11. The inner core 13 is an overall structure composed of three fan-shaped tubes with the same radius, and the radius of the fan-shaped tubes is equal to the inner diameter of the outer tube. half of. Wherein, the fan angles of the three fan-shaped tubes are all 120 degrees.

Embodiment 3

[0027] A high-speed perforated tubular electrode with a cross-sectional shape such as Figure 5 As shown, an outer tube 11 is included, and an inner core 14 is arranged in the axial direction of the outer tube 11. The inner core 14 is an overall structure composed of four fan-shaped tubes with the same radius, and the radius of the fan-shaped tubes is equal to the inner diameter of the outer tube. half of. Wherein, the fan angles of the four fan-shaped tubes are all 90 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com