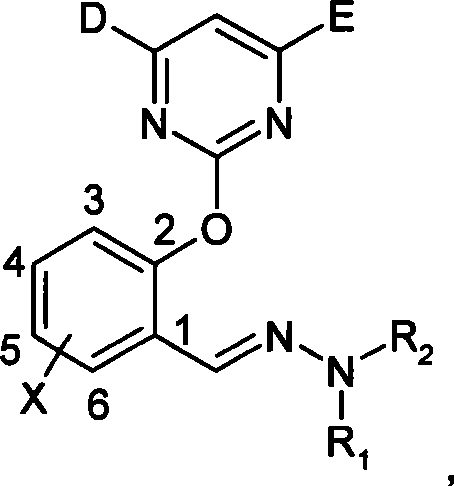

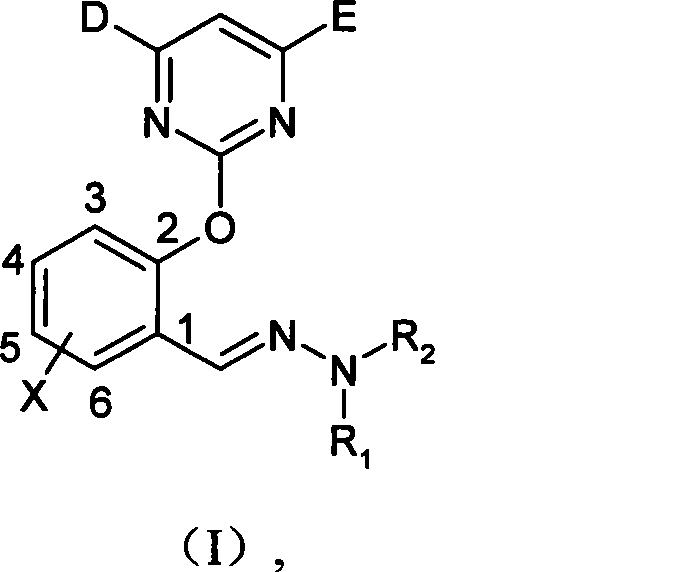

(2-pyrimidine oxygen base)benzaldehyde hydrazone compounds, preparation method and uses thereof

A kind of technology of benzaldehyde hydrazone and pyrimidineoxy, applied in the field of agrochemical herbicides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

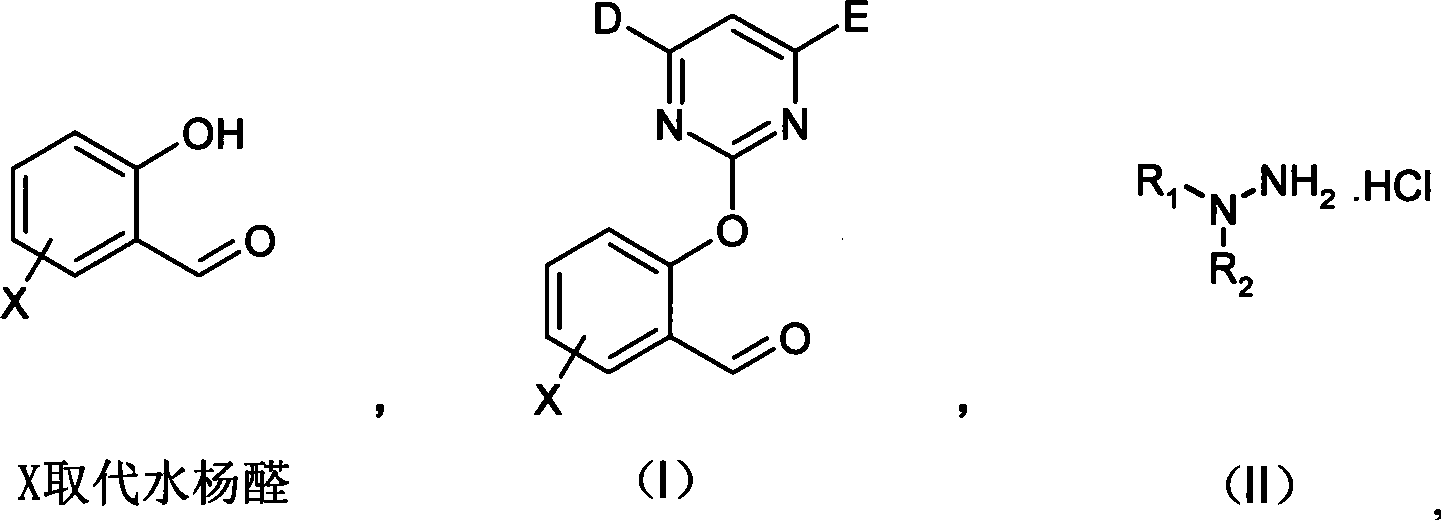

Method used

Image

Examples

Embodiment 1

[0045] Synthesis of (2-pyrimidinyloxy)benzaldehyde hydrazones

[0046] Take 1 synthesis as an example:

[0047] The first step: Condensation with 4,6-dimethoxy-2-thiamphenicol pyrimidine: 15.6g (0.1mol) 6-chloro salicylaldehyde, 21.8g (0.1mol) 4,6-dimethoxy - 2-thiamphenicol pyrimidine, react with 41.4g (0.3mol) of anhydrous potassium carbonate in 150mL of acetonitrile in an oil bath at 40°C for 8-9h, and control the end point of the reaction by TLC. After filtration and spin-drying, petroleum ether and ethyl acetate were recrystallized to obtain 15.4 g of pure product with a yield of 69.3%.

[0048] The second step: Condensation with pyrimidine salicylaldehyde: Dissolve 286mg (1.6mmol) m-chlorophenylhydrazine hydrochloride in a mixed solvent of ethanol and water, add dropwise 0.25ml (1.8mmol) triethylamine to dissolve m-chlorophenylhydrazine free out. Then 470mg (1.6mmol) of 6-chloropyrimidine salicylaldehyde was added to the reaction solution, and stirred at room temperat...

Embodiment 2

[0055] 2, the detailed experimental steps are the same as in Example 1: (1) Condensation with 4,6-dimethoxy-2-thiamphenicol pyrimidine: 0.1mol6-chloro salicylaldehyde in charge, 15.4g of product is obtained, yield 69.3%. (2) Condensation with pyrimidine salicylaldehyde: feed amount 1.6 mmol o-chlorophenylhydrazine hydrochloride, recrystallization from petroleum ether and ethyl acetate to obtain 230 mg of pure product, yield 36.1%.

[0056] solid

[0057] m.p.: 133.6±0.5℃

[0058] 1 H NMR (300MHz, DMSO): δ 3.74 (6H, s, OCH 3 ), 5.96 (1H, s, CH), 6.73-7.48 (7H, m, CH), 8.53 (1H, s, CH), 10.12 (1H, s, NH)

[0059] MS (ESI): 419 (M+H + ), 441 (M+Na + ), 473 (M+MeOH+Na + )

[0060] E.A. for C 19 h 16 Cl 2 N 4 o 3

Embodiment 3

[0062] 3, the detailed experimental steps are the same as in Example 1: (1) condensation with 4,6-dimethoxyl-2-thiamphenicol pyrimidine: feeding amount 0.1mol6-chloro salicylaldehyde, product 15.4g, yield 69.3%. (2) Condensation with pyrimidine salicylaldehyde: feed amount 1.6 mmol p-chlorophenylhydrazine hydrochloride, recrystallization from petroleum ether and ethyl acetate to obtain 257 mg of pure product, yield 40.3%.

[0063] 1 H NMR (300MHz, DMSO): δ 3.74 (6H, s, OCH 3 ), 5.96 (1H, s, CH), 6.71-7.44 (7H, m, CH), 8.53 (1H, s, CH), 10.14 (1H, s, NH)

[0064] MS (ESI): 419 (M+H + ), 441 (M+Na + ), 473 (M+MeOH+Na + )

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com