Uses of tea polysaccharide extract-dihydromyricetin and its esterified matter as anti-oxidant in superpolymer

A technology of dihydromyricetin and ester compound is applied in the field of materials to achieve the effects of good thermal stability and obvious anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

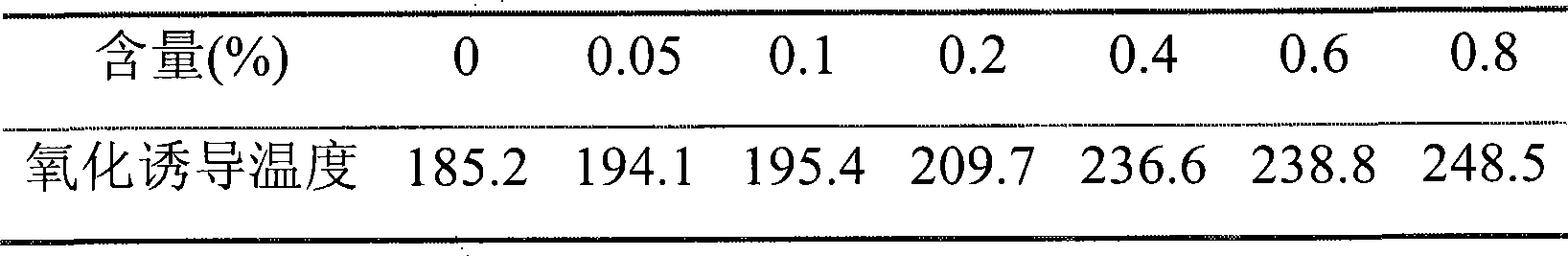

[0016] After the polypropylene resin and dihydromyricetin are fully mixed according to the ratio in Table 1, they are rolled in an open plastic refining machine for 3 minutes, and the temperature of the double rollers is 180±5°C to make a 2mm sample.

[0017] The oxidation induction temperature of the sample was measured using a differential scanning calorimeter (DSC). The oxidation induction test was carried out in an oxygen atmosphere with a flow rate of 20 mL / min. Keep the temperature at 50°C for 2 minutes; raise the temperature at a rate of 10°C / min, when the polypropylene starts to degrade rapidly, the heat flow will change significantly, and the temperature at this time is the oxidation induction temperature.

[0018] Table 1 Oxidation induction temperature (℃) of polypropylene with different proportions of dihydromyricetin added

[0019]

[0020] It can be seen from Table 1 that dihydromyricetin has a good antioxidant effect on polypropylene.

Embodiment 2

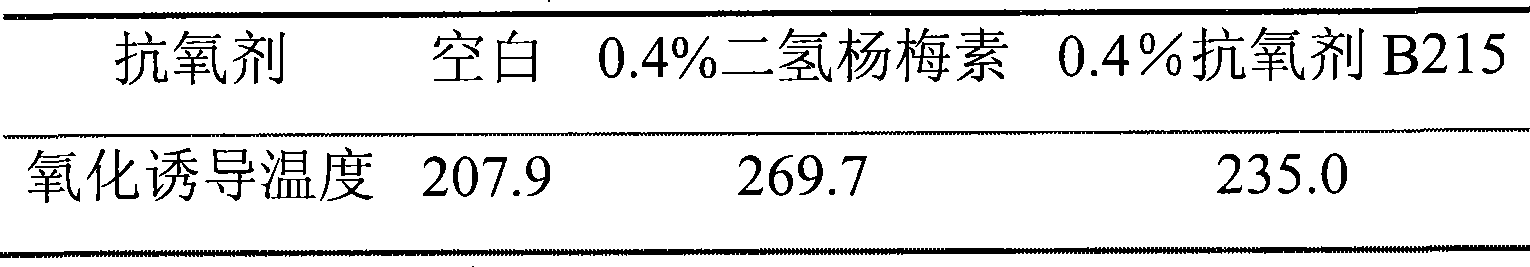

[0022] Fully mix the linear low density polyethylene and the antioxidant according to the ratio in Table 2, roll in the open plastic refining machine for 3 minutes, and the temperature of the double rolls is 120±5°C, and make a 2mm sample.

[0023] Oxidation induction temperature test conditions are the same as above.

[0024] Table 2 Oxidation induction temperature of linear low density polyethylene (℃)

[0025]

[0026] It can be seen that the antioxidant effect of dihydromyricetin on linear low density polyethylene is much better than that of composite antioxidant B215.

Embodiment 3

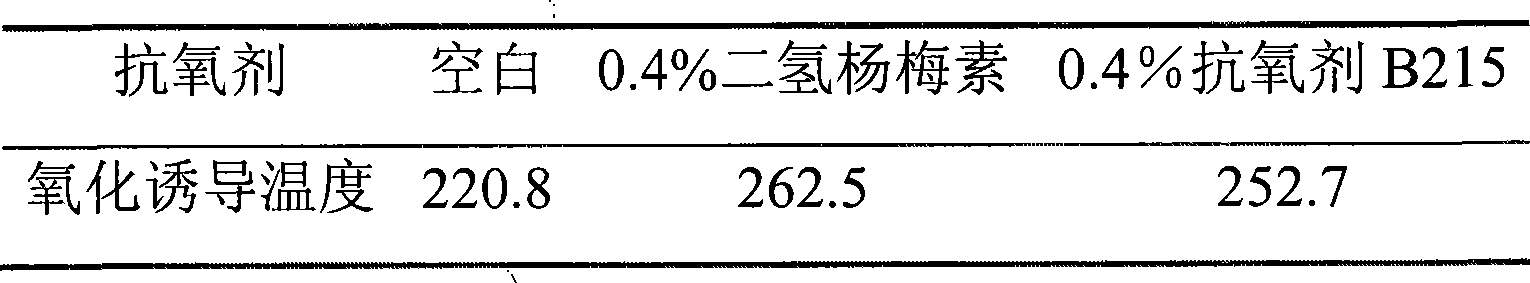

[0028] Fully mix high-density polyethylene and antioxidant according to the ratio in Table 3, and roll in an open plastic refining machine for 3 minutes, and the temperature of the double rolls is 130±5°C to make a 2mm sample.

[0029] Oxidation induction temperature test conditions are the same as above.

[0030] Table 3 Oxidation induction temperature of HDPE (℃)

[0031]

[0032] It can be seen from Table 3 that the antioxidant effect of dihydromyricetin on high-density polyethylene is better than that of compound antioxidant B215.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com