Preparation method for Chinese red pine dissolving pulp

A technology of masson pine and dissolving pulp, which is applied in the direction of spinning solution preparation, chemical preparation of bast fiber, fiber chemical characteristics, etc., can solve the problems of complex process flow and high consumption of chemical preparations, and achieve environmental pollution reduction, chemical preparations and The effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

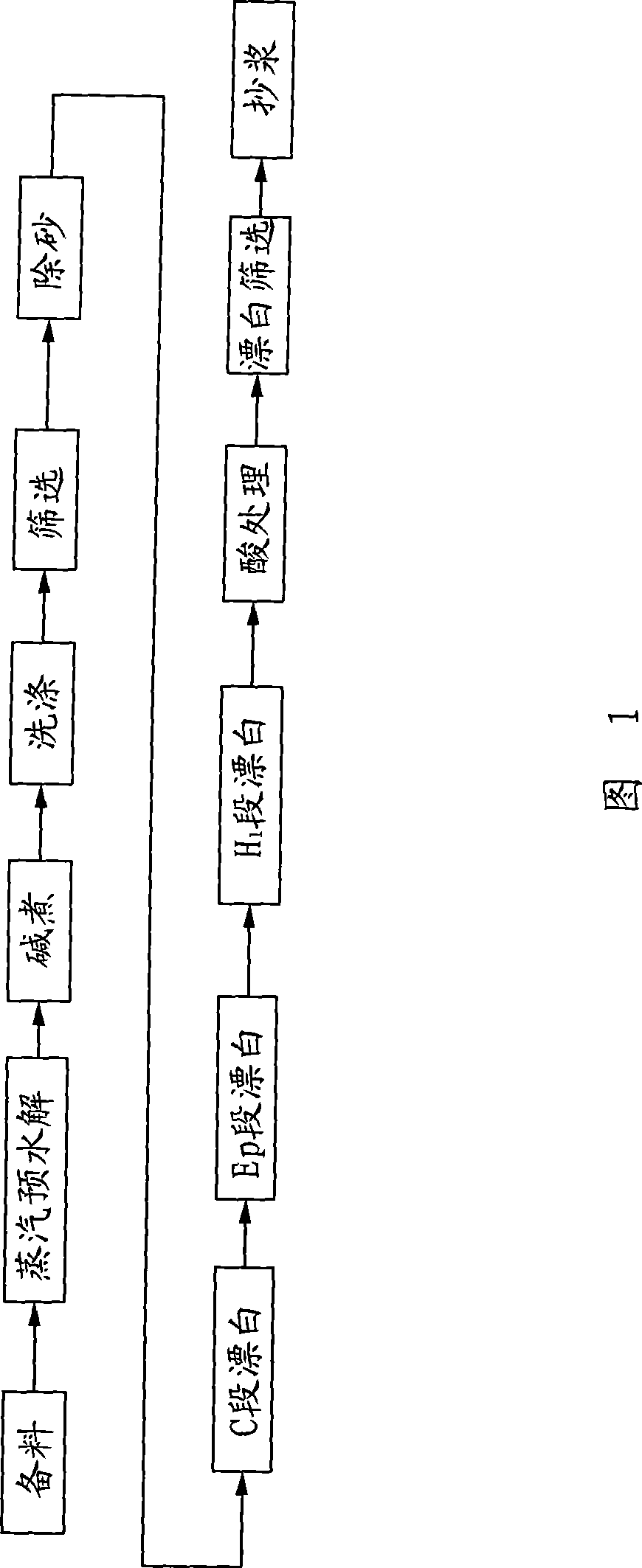

Image

Examples

Embodiment Construction

[0037] A preparation method for masson pine dissolving pulp, comprising the following steps:

[0038] 1) Prepare materials, select 5-10-year-old Masson pine and cut it into sheets with a specification of 25×25×5, and the moisture content of Masson pine is 40%.

[0039] 2) steam prehydrolysis, divided into three stages:

[0040] In the first stage, the initial temperature is raised to 130°C, and the heating time is 40 minutes. After the temperature is raised to 130°C, the air is released once for 5-10 minutes;

[0041] In the second stage, from 130°C to 172°C, the pressure rises to 7.5kg / cm 2 , heating time 30min;

[0042] The third stage, temperature 172 ℃, pressure 7.5kg / cm 2 , keep warm for 50min;

[0043] Finally, drain the liquid. This liquid is called waste acid. The pH value of waste acid is about 3.5. It should be drained as clean as possible. If it is not drained, the amount of alkali used in alkali boiling will be greatly increased. The time is 20 minutes, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com