Control method for field-sequential colorful LED back light source technology

A technology of LED light source and control method, applied in energy-saving control technology, light source, electric light source, etc., can solve the problems of insufficient contrast stretching, only color gamut performance, short service life, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

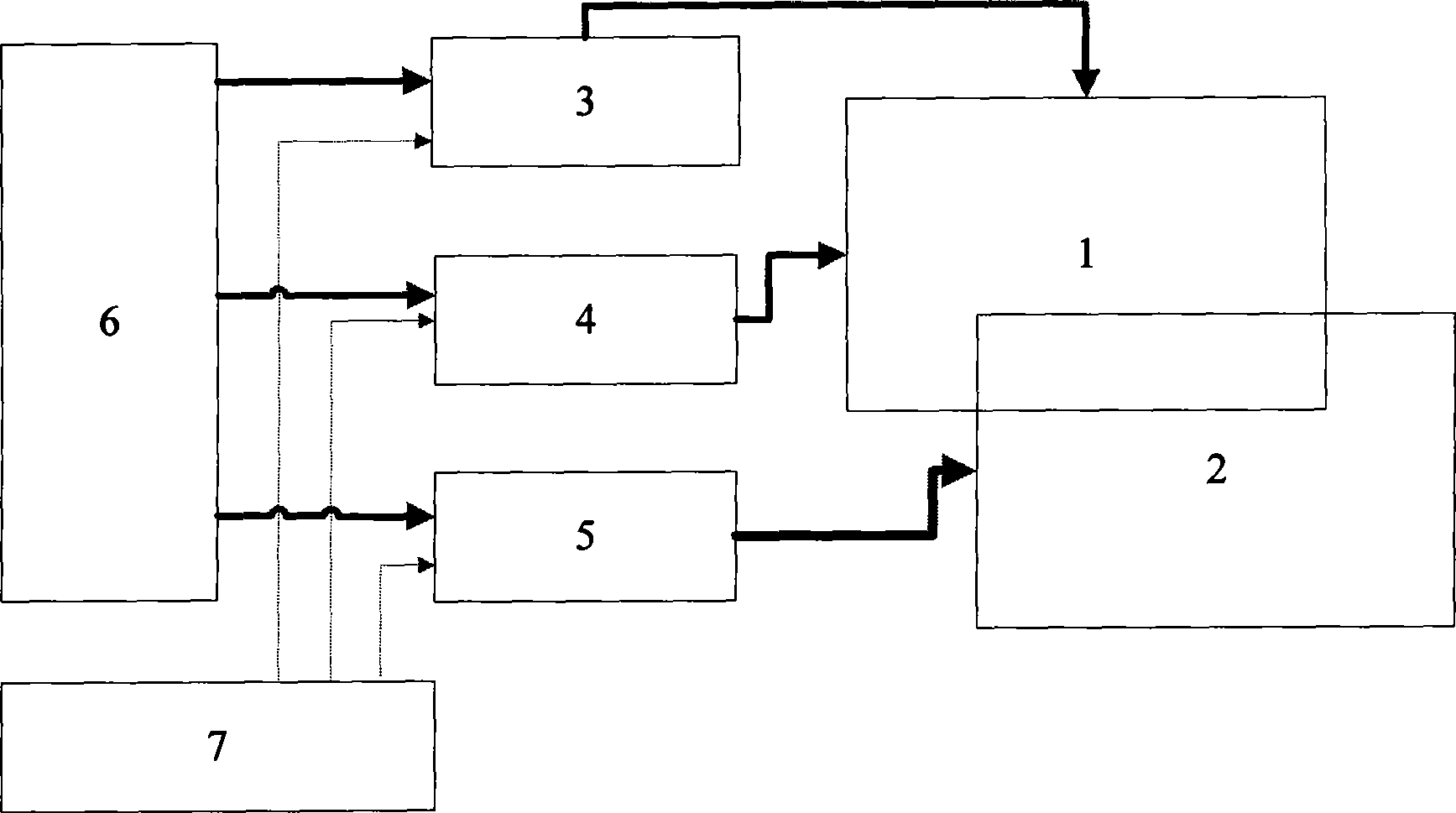

[0024] like figure 1 As shown, according to the present invention, the backlight control system constructed by adopting the color LED light source as the control method of the liquid crystal display backlight is composed of a backlight drive control module 5, an image data acquisition module 6, and an FPGA timing control module 7. The source and gate of the thin film transistors of the liquid crystal panel 1 are respectively controlled by a source drive control module 3 and a gate drive control module 4 . The image data acquisition module 6 transmits the original image data to the source drive control module 3 , the gate drive control module 4 and the backlight drive control module 5 respectively. The source driver 3 and the gate driver control module 4 control the thin film transistors of the liquid crystal panel to pass or block the light of the backlight 2 . After the backlight drive control module 5 receives the image data, it cooperates with the timing output by the FPGA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com