Method for measuring thickness of substrate and equipment for processing substrate

A processing device and thickness measurement technology, applied in measurement devices, grinding devices, optical devices, etc., can solve the problems of unstable interference waves, unstable thickness measurement values, etc., and achieve the effect of stable interference waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

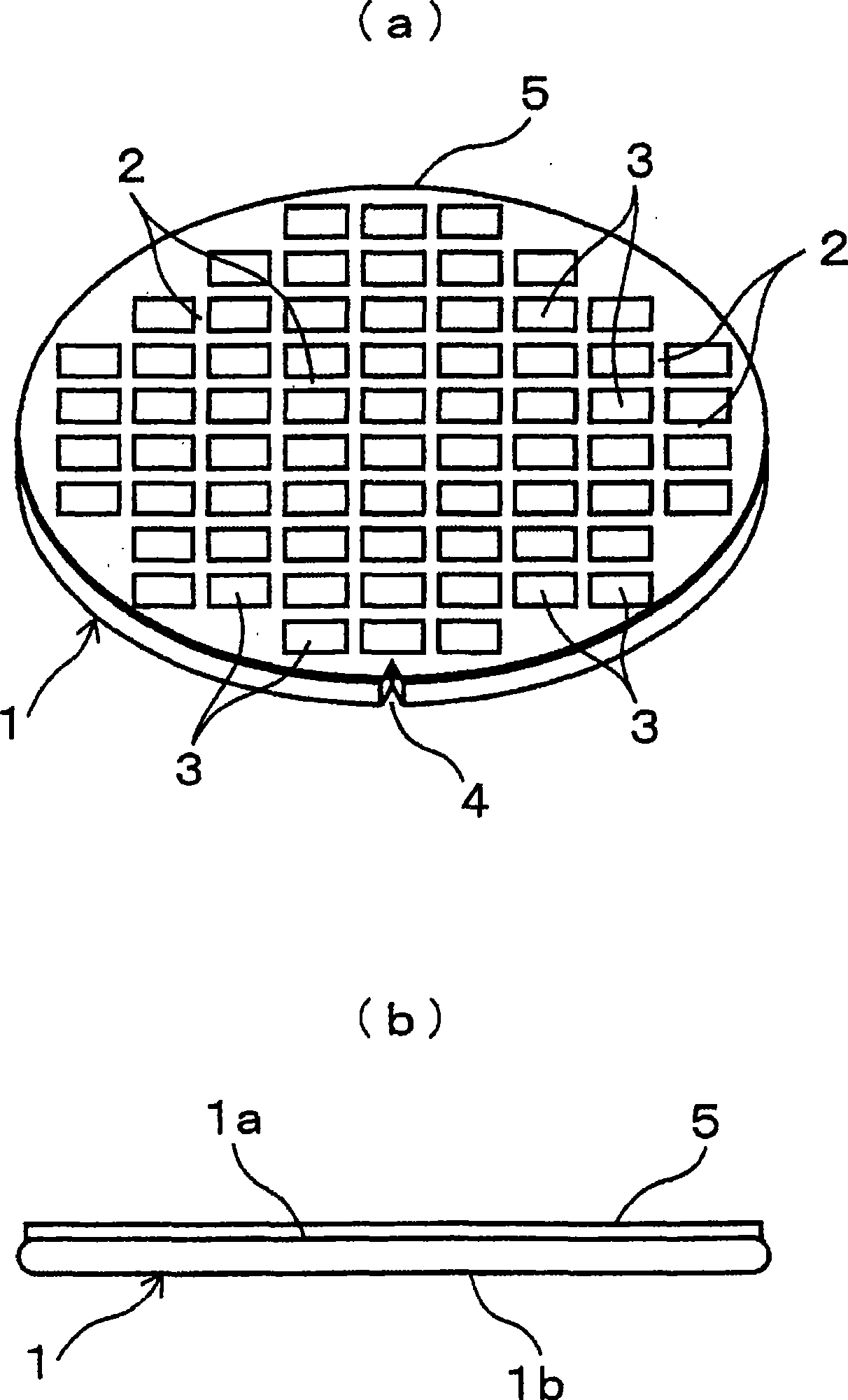

[0034] One embodiment in which the present invention is applied to backside grinding of a semiconductor wafer (substrate) will be described below with reference to the drawings. figure 1 The reference numeral 1 in the figure represents a disk-shaped semiconductor wafer (hereinafter simply referred to as a wafer) thinned by back grinding. This wafer 1 is a silicon wafer or the like, and its thickness before processing is, for example, about 700 μm and is uniform. On the surface (one surface) 1a of the wafer 1, a plurality of rectangular semiconductor chips 3 are divided by grid-like dividing lines 2. As shown in FIG. Electronic circuits (not shown), such as IC (Integrated circuit: integrated circuit) or LSI (large scale integration: large scale integration), are formed on the surfaces of these semiconductor chips 3 . In addition, V-shaped notches (grooves) 4 representing crystal orientations of semiconductors are formed at predetermined positions on the peripheral surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com