Method and apparatus for measuring three-dimensional curved surface based on instantaneous accidental light irradiation

A technology of three-dimensional curved surface and measuring device, which is applied in the field of three-dimensional sensing and measurement, can solve the problems of sensitive structure stability, limited application, low efficiency, etc., and achieve the effect of simple and compact system structure, easy engineering realization and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

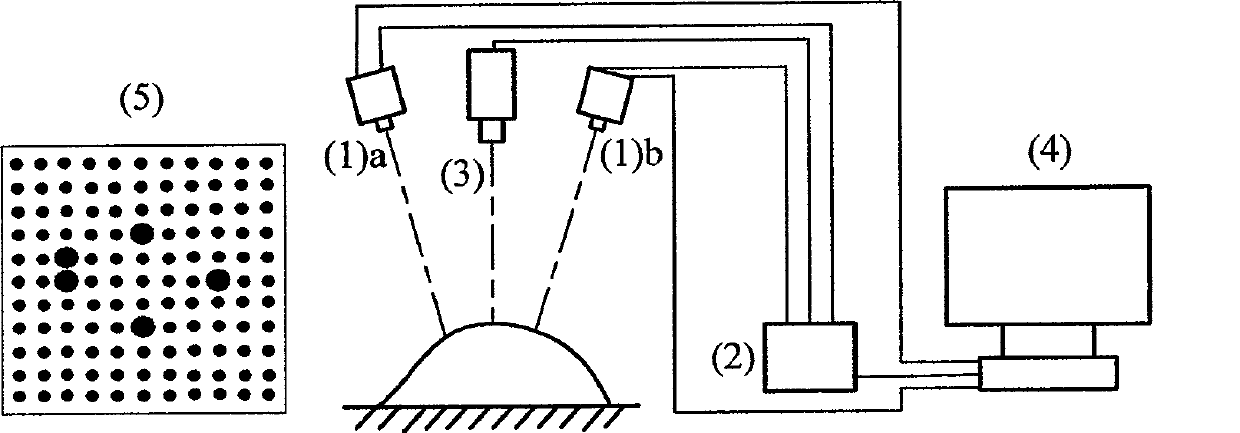

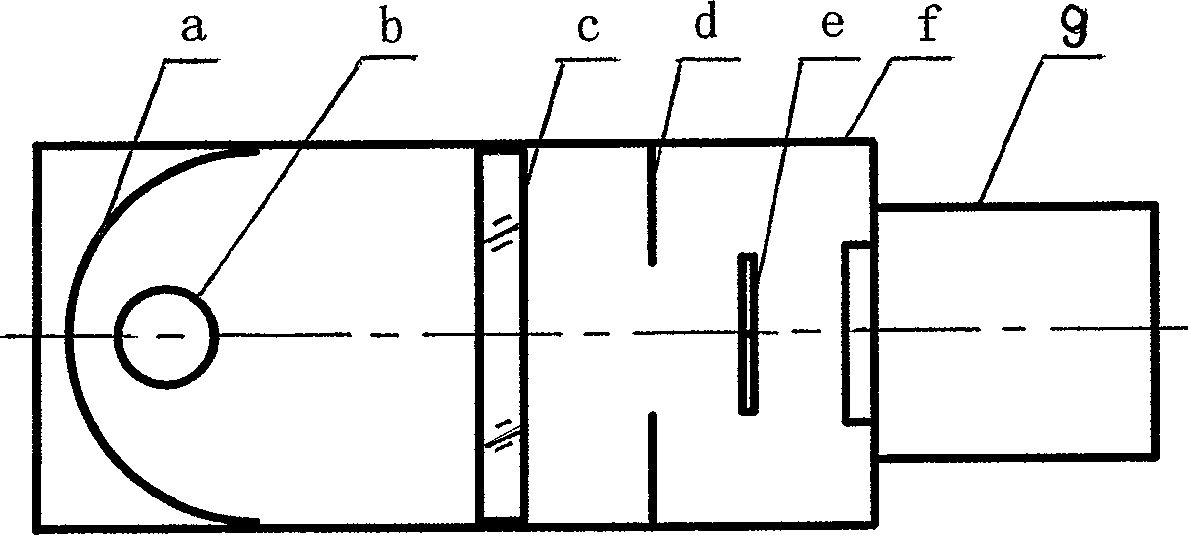

[0026] The measuring device of the present invention comprises a pair of binocular stereo cameras composed of two digital cameras, a control circuit board, a random light field projecting device, a computer and a calibration board. The pair of binocular stereo cameras and the random light field projection device are connected with the control circuit board through the control line, and the control circuit board is connected with the computer through the control line, and the connection mode can be a serial port or a parallel port mode. Two digital cameras pick up images and send them back to the computer, which can be realized through image acquisition cards or IEEE1394.

[0027] The three-dimensional curved surface measurement method based on random illumination of the present invention is implemented by the above-mentioned three-dimensional curved surface measurement device, and the measurement process is as follows:

[0028] In the first step, the inherent imaging parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com