Production method of cassava food

A production method and cassava technology, applied in the field of cassava food production, can solve the problems of no cassava flavor, direct consumption by consumers, and inability to use cassava flour, etc., and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of embodiment 1 cassava whole powder (1)

[0023] 1. Raw material selection

[0024] Choose mature and fresh cassava roots, and remove germinated, green, and moldy cassava.

[0025] 2. Cleaning

[0026] After removing the sundries in the cassava raw material, it is cleaned.

[0027] 3. Peeling

[0028] Manually peel off the cassava skin and rinse it with water.

[0029] 4. Slicing

[0030] The peeled cassava is cut into thin slices of 10-20 mm by a slicer.

[0031] 5. Precooked

[0032] The cassava chips are pre-cooked in hot water at 75°C for 10-20 minutes, the starch forms a gel in the cassava cells and at the same time inactivates the enzymes.

[0033] 6. Steaming

[0034] Use a vertical pressure steam sterilizer (Shanghai Shen'an Medical Equipment Factory, LDZX-30KBS), steam the precooked and cooled potato chips at 0.05 MPa for 30 minutes at a temperature of 100 ° C, and the cassava chips are evenly softened.

[0035] 7. Air drying

[0036]...

Embodiment 2

[0041] The preparation of embodiment 2 cassava whole flour (2)

[0042] Steps 1 to 6 are the same as in Example 1;

[0043] 7. Mix with cassava powder

[0044] Take the dried whole cassava powder and mix evenly with the steamed cassava chips. The amount of dried cassava powder is 2 to 4 times the volume of cassava chips.

[0045] Steps 8 to 10 are the same as steps 7 to 9 in Example 1

[0046] 11. Boiling drying

[0047] Put the sieved whole cassava powder into a boiling dryer to dry again until the moisture content of the whole cassava powder is lower than 9%.

Embodiment 3

[0048] Embodiment 3 cassava powder finished product inspection

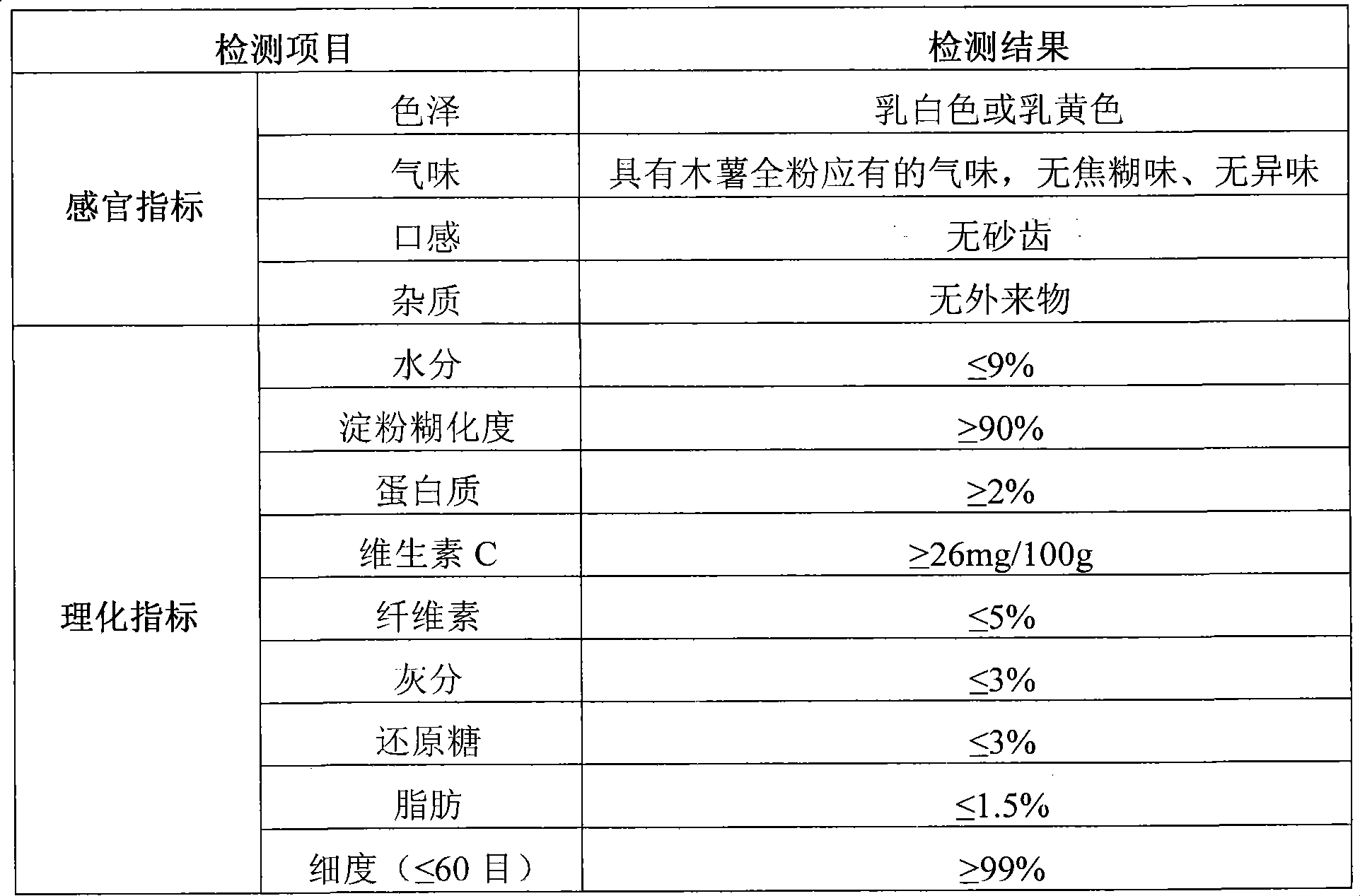

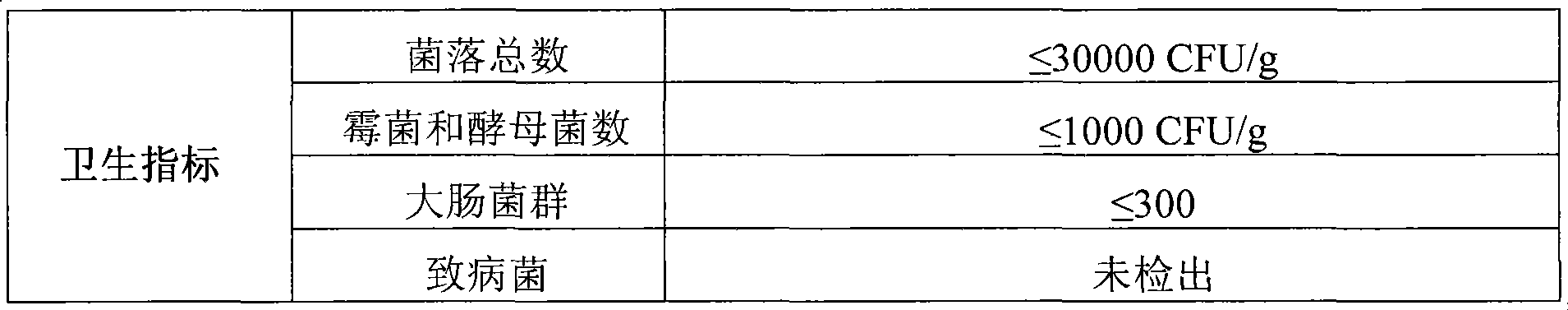

[0049] 1. Detection of sensory indicators, physical and chemical indicators and hygiene indicators

[0050]

[0051]

[0052] The determination of starch gelatinization degree in the table is to prepare a fully gelatinized sample by heating, then carry out enzymatic hydrolysis, precipitate and filter impurities, and finally use Fehling's reagent to develop color, and calculate the corresponding gelatinization degree value by detecting the absorbance value. The determination method refers to the simple enzymatic method [Xiong Yiqiang, Determination of gelatinization degree of feed starch, Feed Industry, 2001, 3(21): 30-31].

[0053] 2. Thermal stability

[0054] The process of thermal denaturation and thermochemical denaturation of cassava whole flour samples was measured by DSC-6200 differential scanning calorimeter from Seiko Instruments Company of Japan. The heat denaturation temperature range of cassav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com