Technological process for producing reduced iron fine-powder

A process method and iron fine powder technology are applied in the field of secondary reduction iron powder production technology, which can solve problems such as high carbon content and inability to meet the technical requirements of iron fine powder, achieve low production cost, improve product quality, and process Reasonable effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Put the primary reduced iron powder with a content of 98.5% into the steel belt-type iron fine powder reduction furnace, then heat the reduction furnace, and when the temperature rises to 800-850°C, feed the decomposed ammonia gas (liquid ammonia is pyrolyzed into 75 %H 2 +25%N 2 Mixed gas), continuously input iron powder and reducing gas at this reduction temperature, and control the flow rate of ammonia gas at 45-50m 3 / hour, and at the same time into the water vapor and hydrogen chloride gas, the flow rate is 5 ~ 7m 3 / hour, the mixing volume ratio of water vapor and hydrogen chloride gas is 1:0.1~0.2, the temperature of water vapor is 120~150°C, the dew point of decomposed ammonia gas is controlled at -30~-50°C, when the reduction reaction time reaches 3~4 hours , and continue to keep warm at 850° C. to 900° C. for 1 to 2 hours to obtain the final product.

Embodiment 2

[0012] Input the primary reduced iron powder with a content of 98.0% into the steel belt-type iron fine powder reduction furnace, and then heat the reduction furnace. When the temperature rises to 800-850°C, the decomposed ammonia gas (liquid ammonia is pyrolyzed into 75 %H 2 +25%N 2 Mixed gas), continuously input iron powder and reducing gas at this reduction temperature, and control the flow rate of ammonia gas at 45-50m 3 / hour, and at the same time into the water vapor and hydrogen chloride gas, the flow rate is 8 ~ 10m 3 / hour, the mixing volume ratio of water vapor and hydrogen chloride gas is 1:0.1~0.2, the temperature of water vapor is 120~150°C, the dew point of decomposed ammonia gas is controlled at -30~-40°C, when the reduction reaction time reaches 3~4 hours , and continue to keep warm at 850° C. to 900° C. for 1 to 2 hours to obtain the final product.

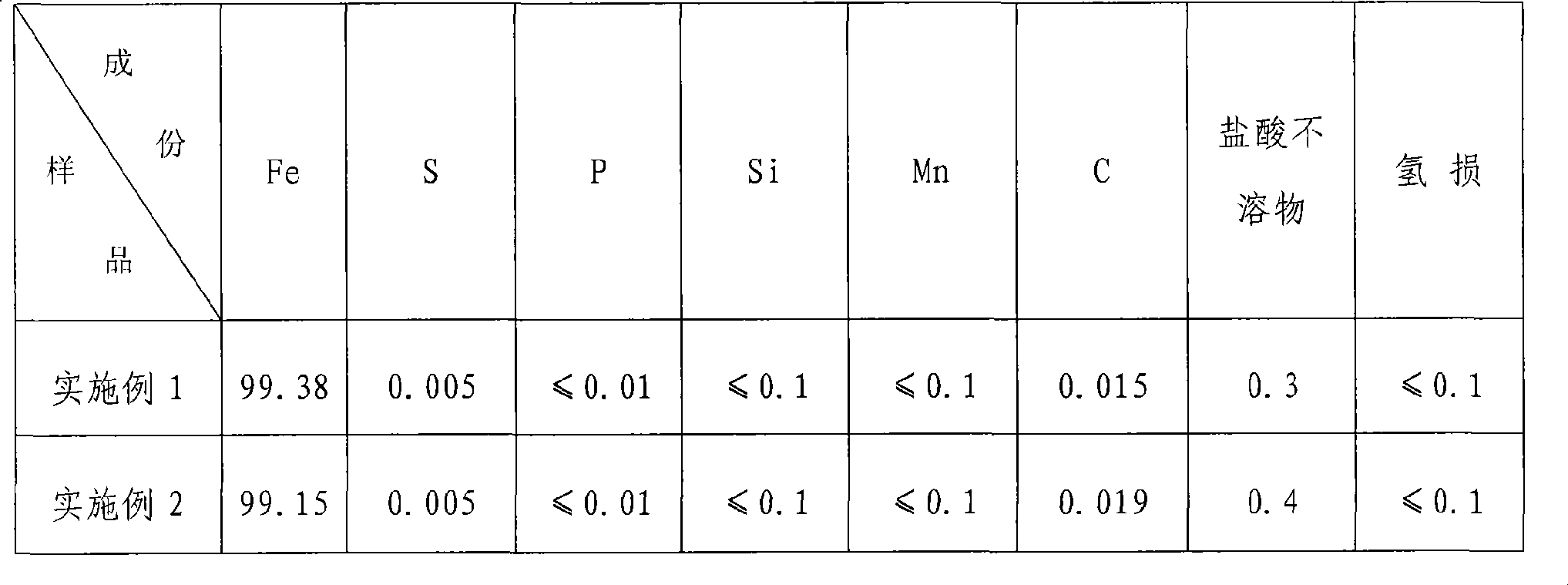

[0013] The list of product inspection results is as follows: (unit wt%)

[0014]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com