Method for synthesizing molybdenum dioxide-carbon composite nano-wire

A technology of molybdenum dioxide and a synthesis method, applied in the field of nanomaterials, can solve the problems of low yield and complicated operation, and achieve the effects of high product quality and yield, high preparation efficiency, and adjustable length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

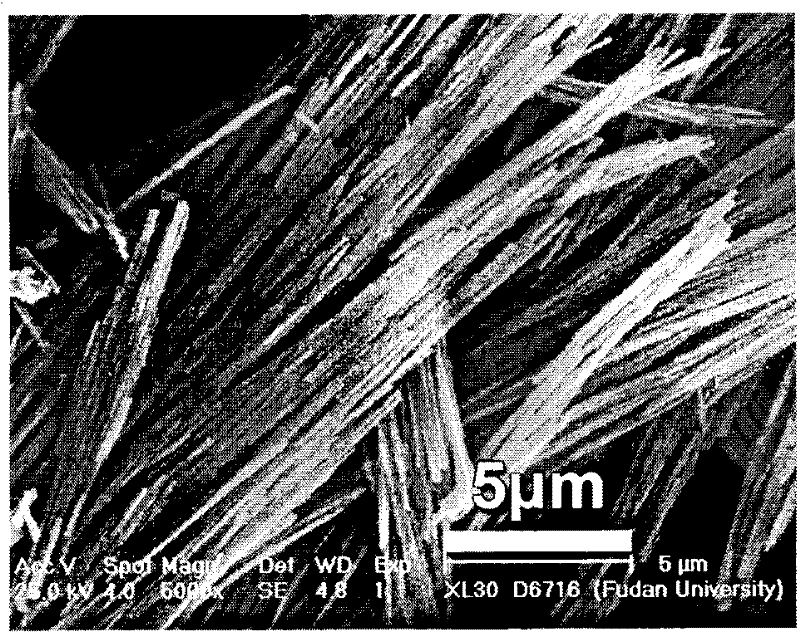

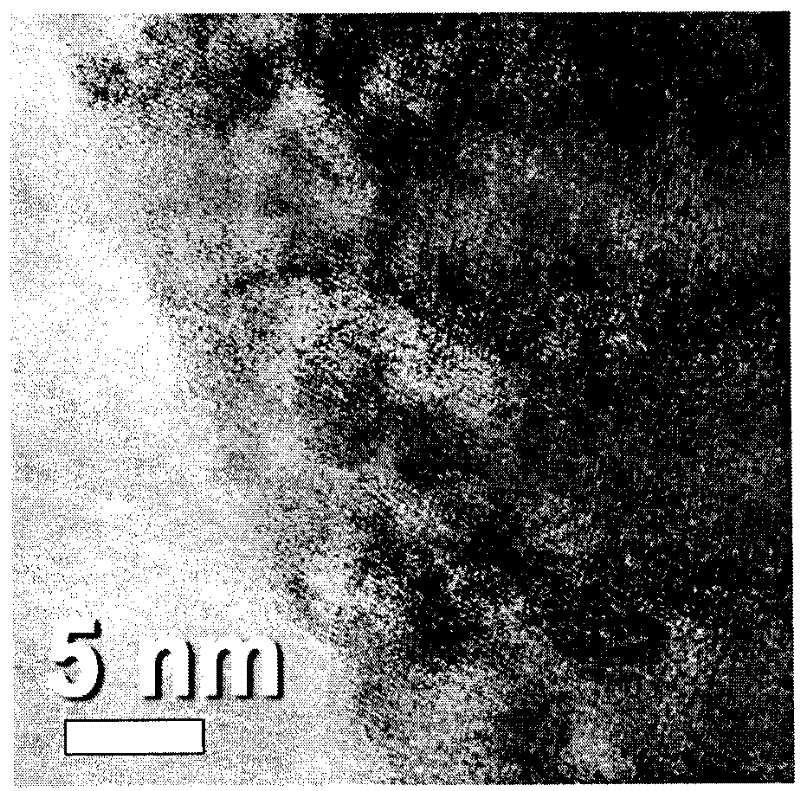

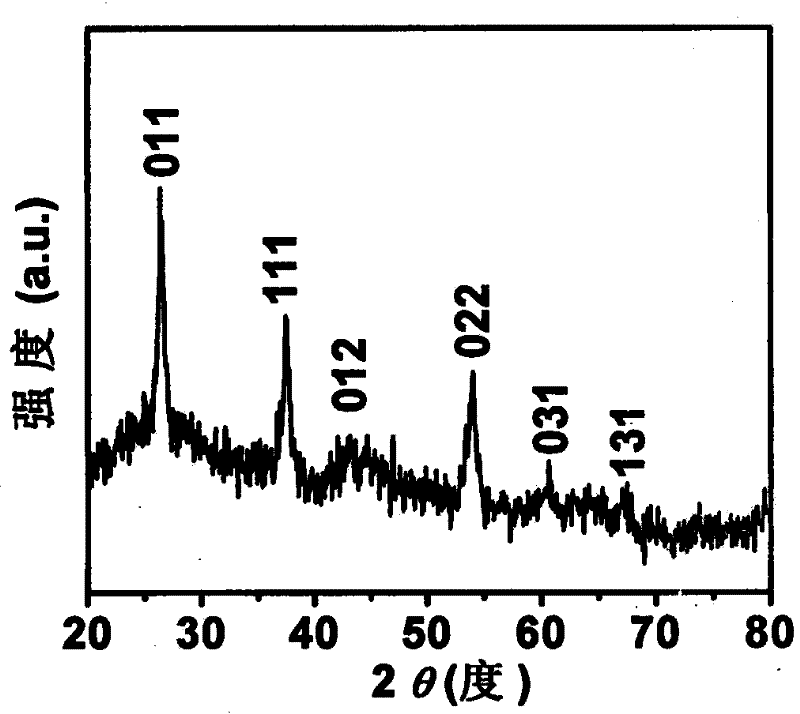

[0044] A method for synthesizing molybdenum dioxide-carbon composite nanowires, comprising the steps of:

[0045] (1) 1.24g ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O is dissolved in 20mL distilled water to obtain ammonium molybdate solution (molar molar concentration of molybdenum is about 0.35mol / L);

[0046] (2) Inject 1.73g of aniline into the ammonium molybdate solution (the molar ratio of aniline to molybdenum atoms is about 2.65:1);

[0047] (3) Add 1.0 mol / L hydrochloric acid dropwise to the solution, adjust the pH to 4-5, until a white precipitate appears, and prepare a reaction solution;

[0048] (4) The reaction solution was transferred to an oil bath at 50° C., and reacted for 6 hours to obtain the product;

[0049] (5) The product was washed several times with absolute ethanol, filtered with suction, and dried at 50°C;

[0050] (6) Finally, the product was calcined in an argon flow at a calcining temperature of 575° C. for a calcining time of 5 hours to ob...

Embodiment 2

[0056] A method for synthesizing molybdenum dioxide-carbon composite nanowires, comprising the steps of:

[0057] (1) ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O is dissolved in 20mL distilled water to obtain ammonium molybdate solution (molar concentration of molybdenum atoms is 0.01mol / L);

[0058] (2) Inject aniline into the ammonium molybdate solution (the molar ratio of aniline to molybdenum atoms is 4.0-2.0:1);

[0059] (3) Add 1.0 mol / L hydrochloric acid dropwise to the solution, adjust the pH to 4-5, until a white precipitate appears, and prepare a reaction solution;

[0060] (4) The reaction solution was transferred to an oil bath at 50° C., and reacted for 6 hours to obtain the product;

[0061] (5) The product was washed several times with absolute ethanol, filtered with suction, and dried at 50°C;

[0062] (6) Finally, the product was calcined in an argon flow at a calcining temperature of 575° C. and a calcining time of 5 hours to obtain a molybdenum diox...

Embodiment 3

[0064] A method for synthesizing molybdenum dioxide-carbon composite nanowires, comprising the steps of:

[0065] (1) ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O is dissolved in 20mL distilled water to obtain ammonium molybdate solution (molar concentration of molybdenum atoms is 2.0mol / L);

[0066] (2) Inject aniline into the ammonium molybdate solution (the molar ratio of aniline to molybdenum atoms is 4.0-2.0:1);

[0067] (3) Add 1.0 mol / L hydrochloric acid dropwise to the solution, adjust the pH to 4-5, until a white precipitate appears, and prepare a reaction solution;

[0068] (4) The reaction solution was transferred to an oil bath at 50° C., and reacted for 6 hours to obtain the product;

[0069] (5) The product was washed several times with absolute ethanol, filtered with suction, and dried at 50°C;

[0070] (6) Finally, the product was calcined in an argon flow at a calcining temperature of 575°C for a calcining time of 5 hours to obtain a molybdenum dioxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com