Preparing method for molybdenum oxide - polyaniline composite nanowire and nanotube

A molybdenum oxide, polyaniline technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of difficult preparation and preservation of ion exchange precursors, strict restrictions on synthesis conditions, and complicated operations, and achieve good application and industry. Chemical prospect, product quality and the effect of high yield and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

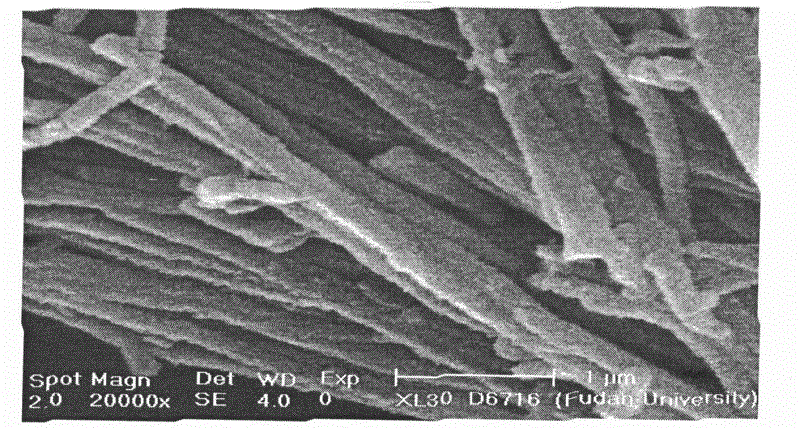

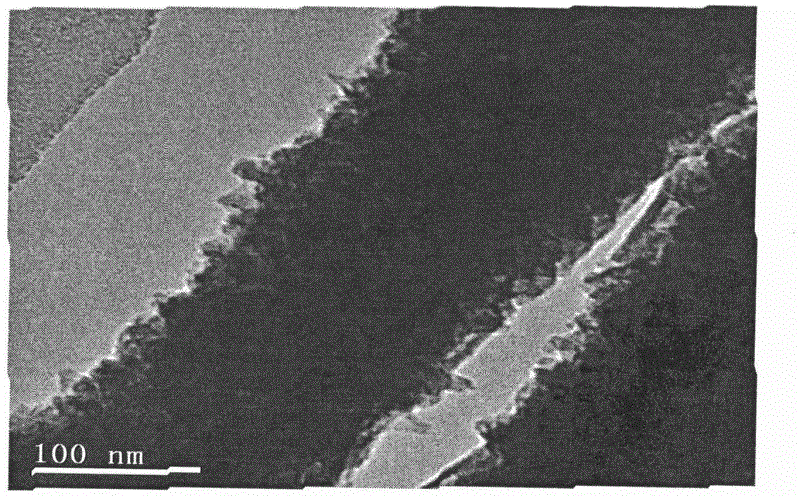

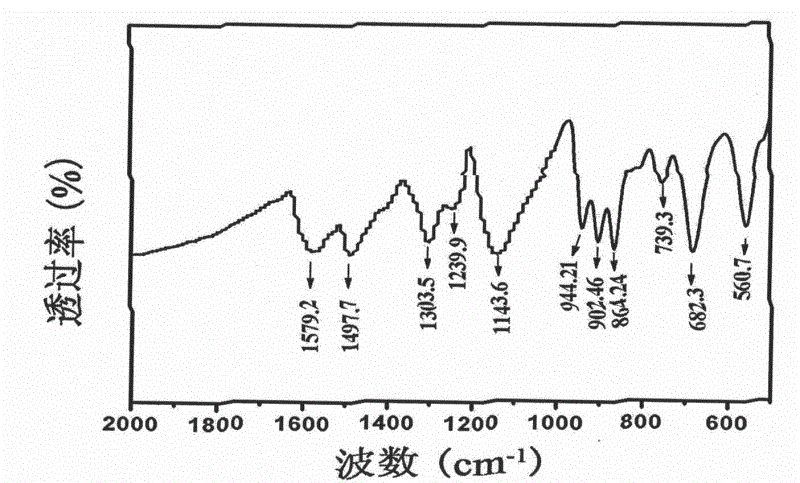

[0048] 1.24g (NH 4 ) 6 Mo 7 o 24 4H 2 Dissolve O in 20 mL of distilled water, inject 1.67 g of aniline, and then add 1.0 mol / L hydrochloric acid dropwise until white precipitate appears (pH 4~5). Transfer to an oil bath at 50°C, react for 6 hours, wash the obtained product with ethanol several times, filter it with suction, and dry it at 50°C. The product is called a precursor. Dissolve 0.355g of the precursor in 10mLPSS, add distilled water after centrifugation, adjust the pH of the system to 1.0 with 0.5mol / L hydrochloric acid, add 0.143g of ammonium persulfate, and react at room temperature for 12 hours to obtain molybdenum oxide-polyaniline composite nanowires A.

Embodiment 2

[0050]Carry out experiment with the method for embodiment 1, ammonium molybdate wherein is changed into sodium molybdate, makes nanowire product A 1 .

Embodiment 3

[0052] Carry out experiment with the method for embodiment 1, change the concentration of ammonium molybdate wherein into 0.01mol / L (calculate in molybdenum atom), make nanowire product A 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com