Method for assessing function of spices monomer to cigarette by pyrolysis experiment

A thermal cracking and spice technology, which is applied to analysis materials, measuring devices, instruments, etc., can solve the problems of not fully considering the combustion temperature distribution of cigarettes, and the effect is not comprehensive enough, and achieve the effects of low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

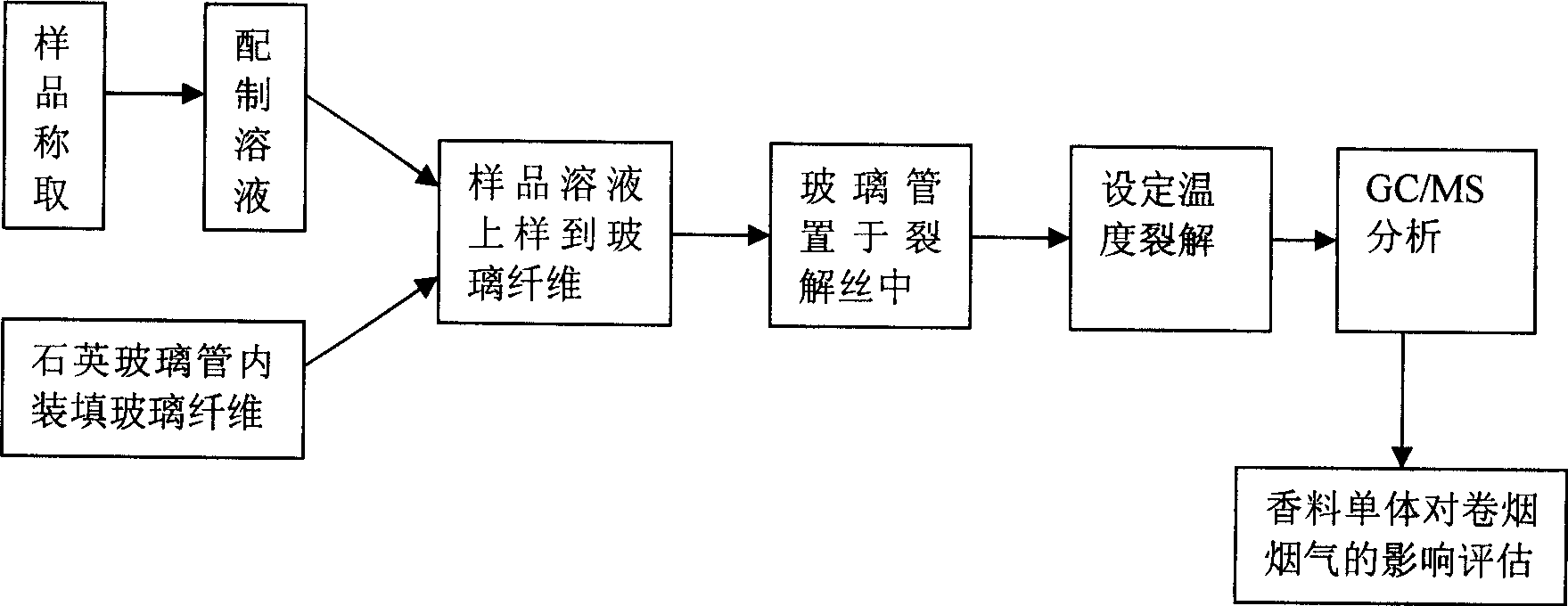

Image

Examples

Embodiment 1

[0017] Isophorone pyrolysis experiment: Accurately weigh 0.5-1.0g sample, dissolve it with ethanol, and transfer it to a 100ml volumetric flask. A certain amount of quartz glass fiber is installed in the quartz glass tube, and 5-10

[0018] μl sample solution is injected onto the quartz glass fiber in the quartz cracking tube. Put it in the lysis filament of the lysis probe, put the lysis probe into the lyser, and start the lysis. The temperature at the interface between the cracker and the gas chromatograph is 250°C. Cracking heating program: Cracking start temperature is 50°C-100°C, keep for 2s, raise the temperature to the set temperature at a heating rate of 5°C-10°C / ms, keep for 20s. Chromatographic column HP-FFAP (30m*0.25mm*0.25μm), inlet temperature 250°C, constant flow 0.6ml / min, split ratio 10:1. Furnace temperature rise program: start at 50°C-80°C, keep for 1min-2min, raise the temperature to 220°C at a heating rate of 5°C-10°C / min, and keep for 10min-30min.

[...

Embodiment 2

[0032] The present embodiment is basically the same as embodiment 1, except that the fragrance monomer is different, which is butyl cinnamate.

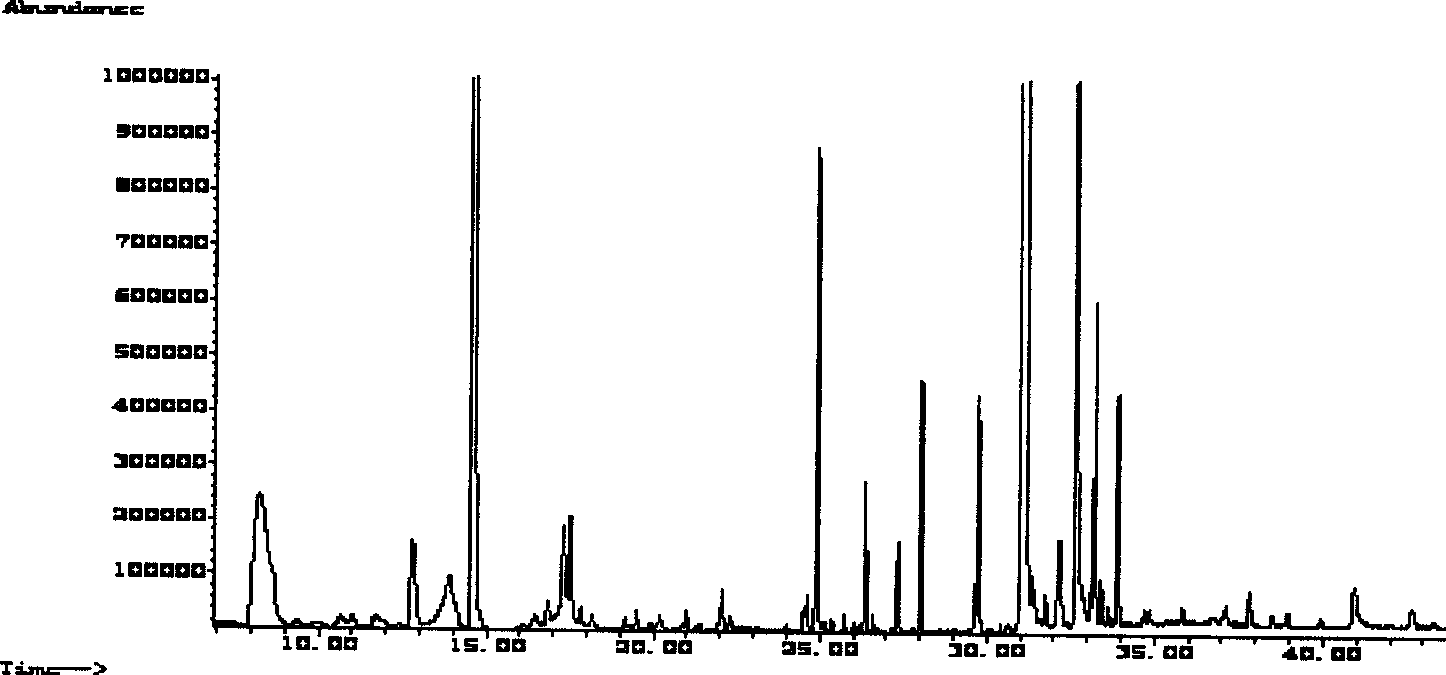

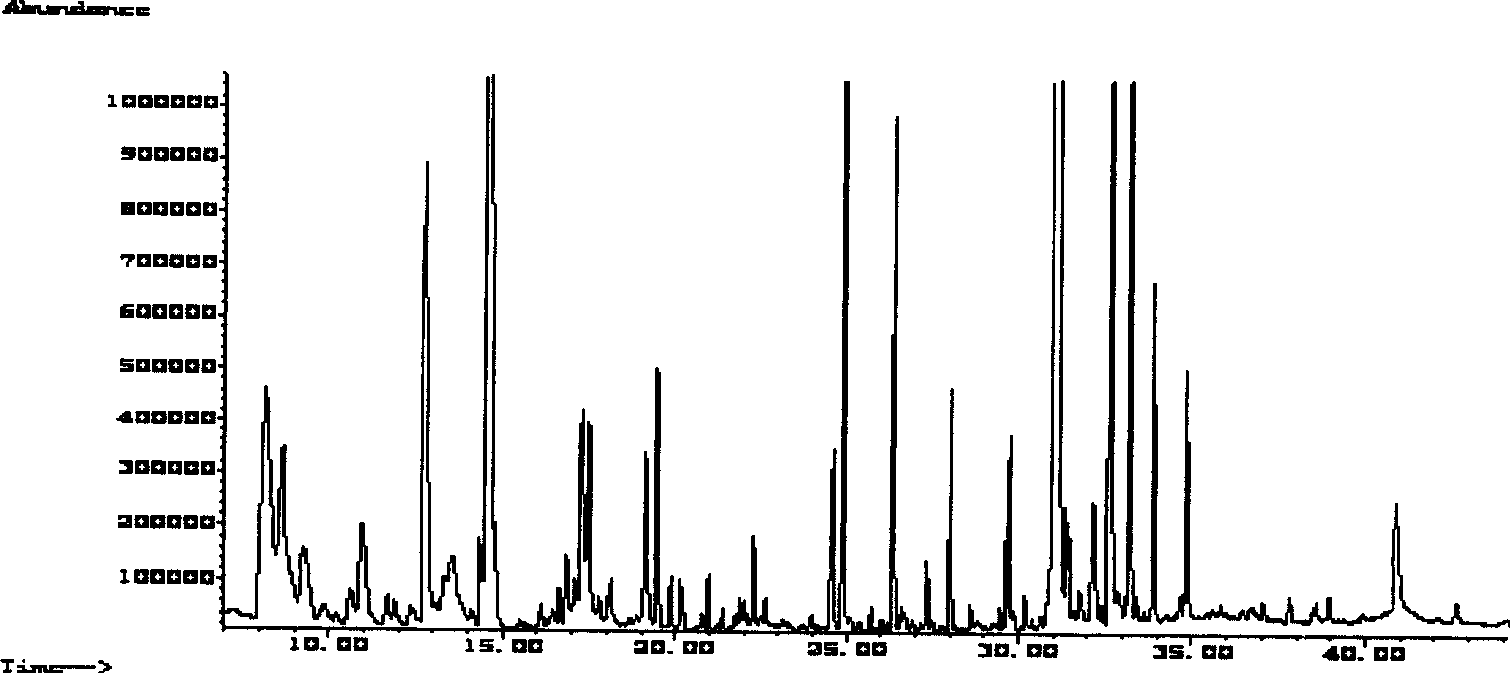

[0033] Thermal cracking experiment of butyl cinnamate: see attached picture: Figure 5 , Figure 6 and Figure 7 The total particle flow mass spectra of butyl cinnamate thermally cracked at 300°C, 600°C, and 900°C, respectively, Table 4 to Table 6 are the total particle flow mass spectra of butyl cinnamate thermally cracked at 300°C, 600°C, and 900°C Graph search results.

[0034] Table 4 Retrieval results of 300℃ pyrolysis of butyl cinnamate

[0035]

[0036] Table 5 Search results of 600℃ pyrolysis of butyl cinnamate

[0037]

[0038]

[0039] Table 6 Search results of 900℃ pyrolysis of butyl cinnamate

[0040]

[0041]The evaluation conclusions of butyl cinnamate pyrolysis: 1. The main components of the pyrolysis products are esters and aldehydes and ketones, which are good f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com