Precoated metal plate

A metal plate and pre-coating technology, which is applied in the direction of metal layered products, metal material coating process, coating, etc., can solve the problem of damage to optical discs, and achieve the effect of good bonding force, high peel strength, and excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

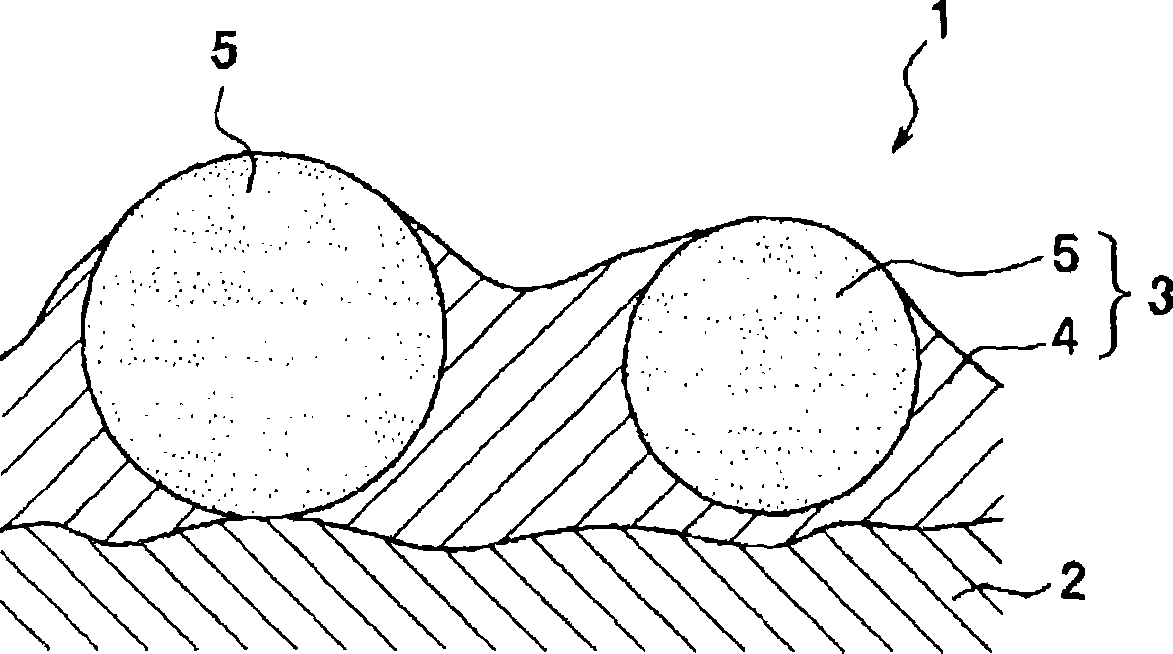

Method used

Image

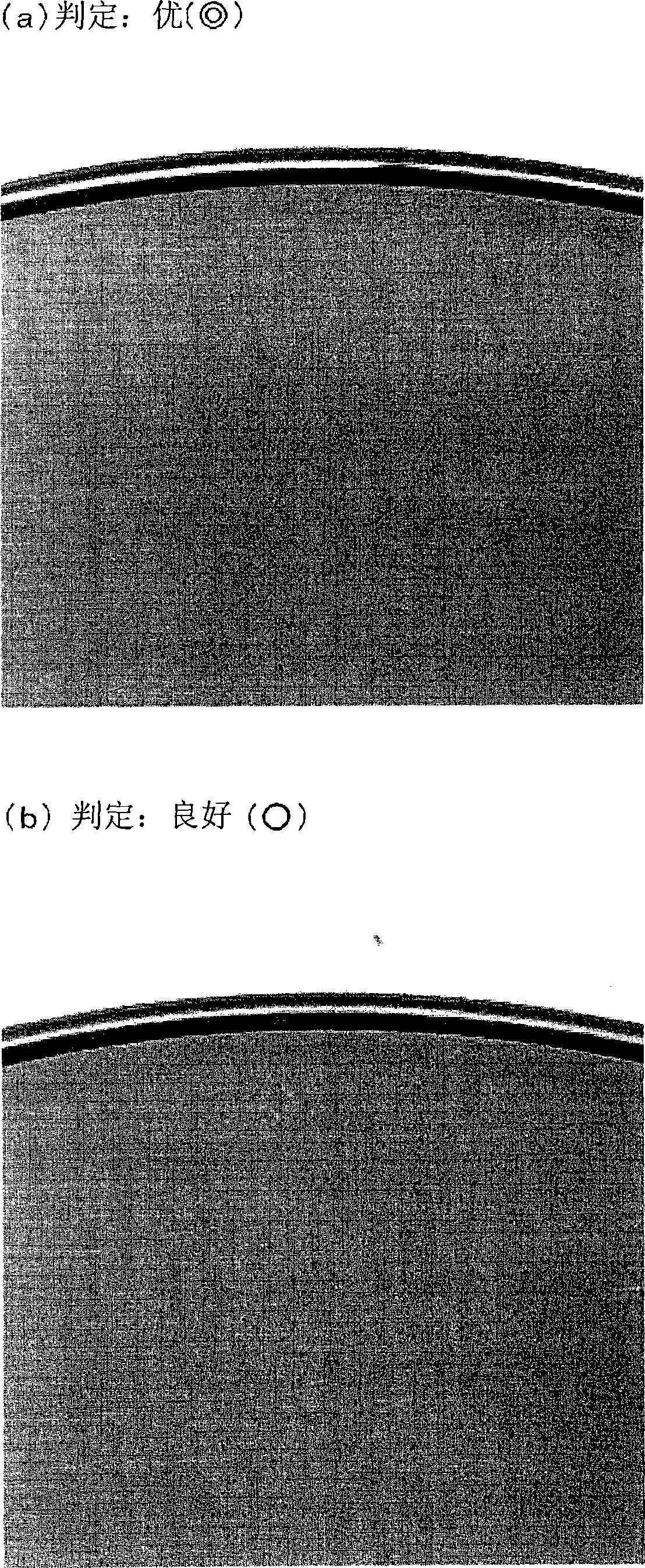

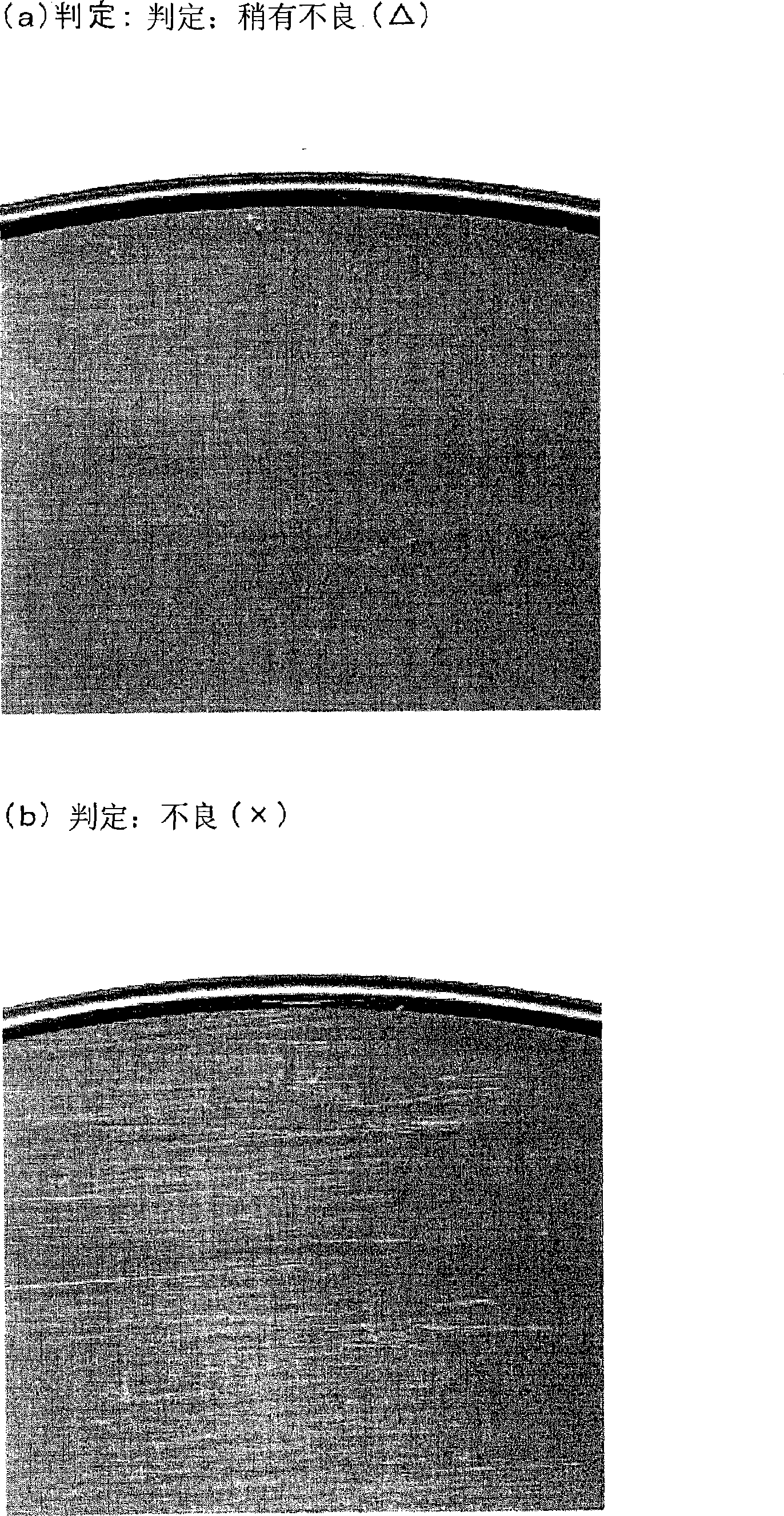

Examples

Embodiment 1~12

[0101] As Examples 1 to 12, precoated metal sheets were produced according to the above-described production method. Each configuration of the precoated metal sheet is as follows.

[0102] (Metal plate)

[0103] The thickness is 0.5mm, and the 5052-H34 aluminum alloy plate specified by JIS is used.

[0104] (corrosion-resistant film)

[0105] Phosphate chromate film is formed on both sides of the aluminum alloy plate. The adhesion amount of the phosphoric acid chromate coating is 20 mg / m in terms of Cr 2 .

[0106] (resin film)

[0107] Coating the epoxy-based paint that makes the soft pellets and tetrafluoroethylene powder disperse the compressive strength when having the 10% deformation specified in the present invention on the outermost surface of the chromate phosphate film, at the sintering temperature (metal plate) The maximum maximum temperature) is sintered at 250°C to form a resin film (fluorine-based resin base layer). Here, as the soft pellets, urethane pelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com