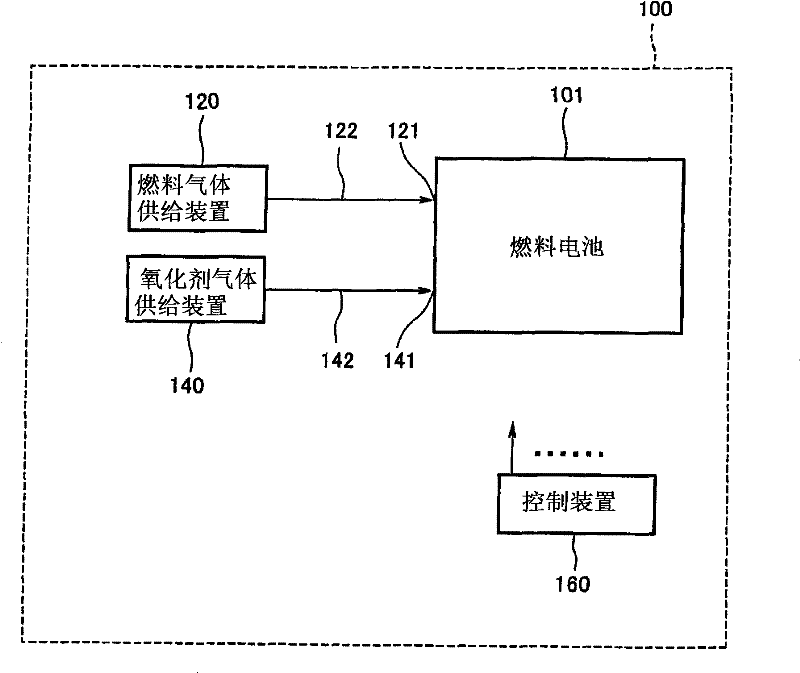

Fuel cell system

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve problems such as uneven concentration and reduced power generation performance of battery stacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

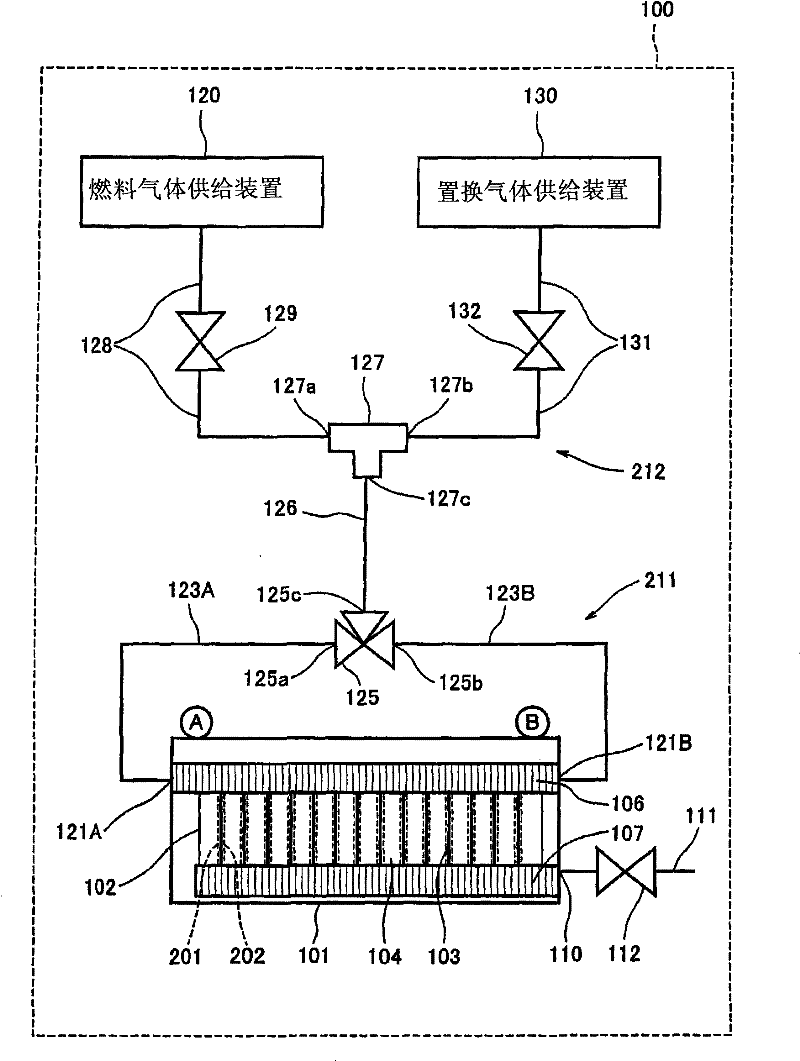

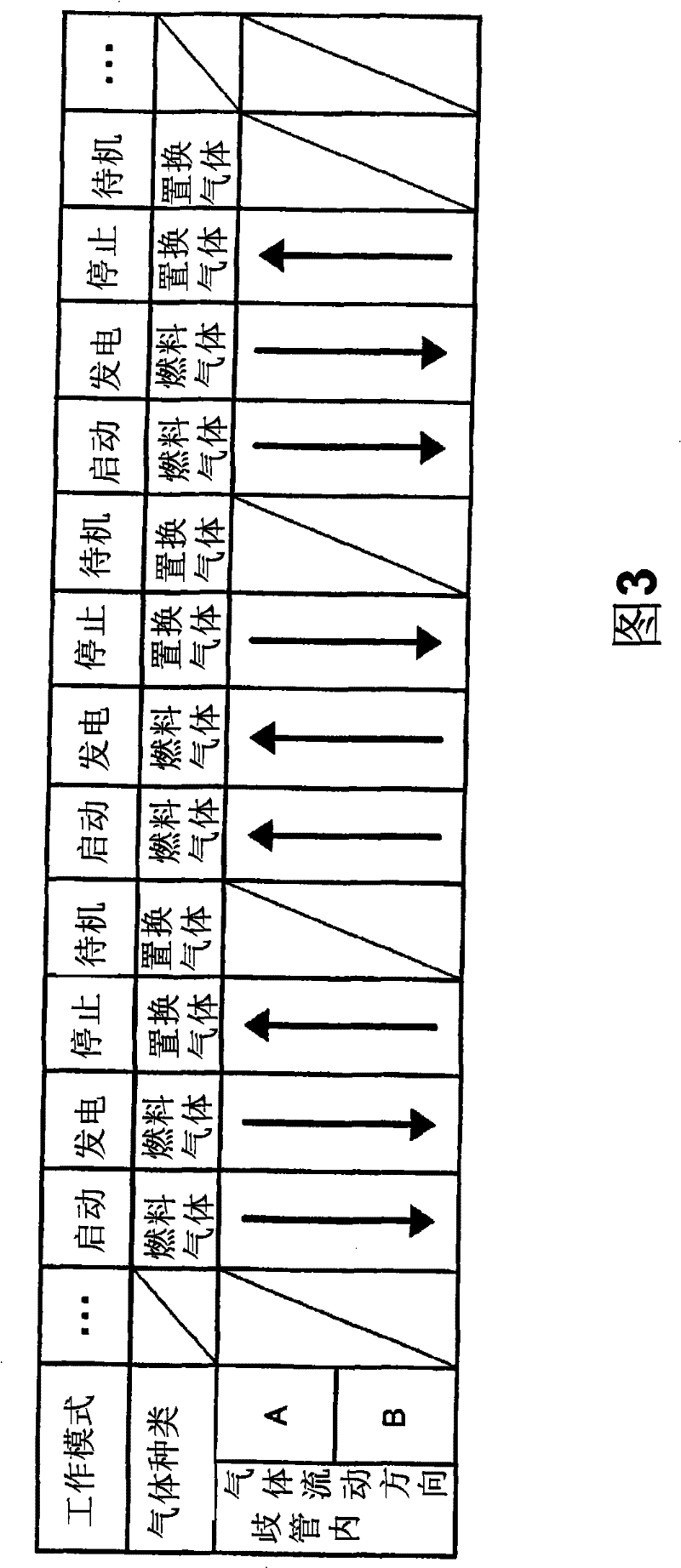

[0172] Figure 6 It is a partial block diagram showing components for supplying fuel gas in the fuel cell system 200 of the present embodiment. Figure 7 is expressed in Figure 6 A diagram showing the flow direction of the fuel gas in the fuel gas supply manifold 106 , which is a component of the fuel cell system 200 . Figure 8 It is a partial block diagram showing components for supplying an oxidant gas in the fuel cell system 200 of the present embodiment. Figure 9 is expressed in Figure 8 The flow direction of the oxidant gas in the oxidant gas supply manifold 108 , which is a constituent element of the fuel cell system 200 , is shown. exist Figure 6 as well as Figure 8 in, for with figure 2 as well as Figure 4 The same or corresponding parts are marked with the same symbols, and their explanations are omitted.

[0173] In the fuel cell system 200 of this embodiment, instead of figure 2 The T-shaped pipe joint 224, the A-side fuel gas supply valve 225A, an...

Embodiment 1

[0212] As an example of the present invention, a fuel cell system 100 including a fuel cell 101 shown below and having the configuration shown in the first embodiment (including switching of the flow direction of the reactant gas) is manufactured.

[0213]Here, only the specific configuration of the fuel cell 101 is shown. A polymer electrolyte fuel cell is used as the fuel cell 101 . Other components of the fuel cell system 100 are configured in a well-known form.

[0214] First, methods for producing the anode and the cathode will be described.

[0215] Acetylene carbon black powder with a particle diameter of 35 nm [Nichiden Denka Industries: DENKA BLACK (registered trademark)] and an aqueous dispersion of PTFE (DAIKIN: D-1) were mixed and prepared to contain a dry weight of 20 Mixture of wt% PTFE. Then, the mixed solution was coated on carbon paper (manufactured by TORAY: TGPH060H) and impregnated, and heat-treated at 300° C. using a hot air dryer to form a gas diffusio...

Embodiment 2

[0227] A fuel cell system 200 having the configuration (including switching of the flow direction of the reactant gas) shown in the second embodiment was fabricated using the same cell stack as the single cell stack shown in the above-mentioned Example 1. As for other operating conditions, it is all the same as the above-mentioned embodiment 1.

[0228] Then, using power generation and stop as a cycle, set the power generation time to 1 hour, set the stop time to 1 hour, and repeat the operation for 1000 cycles. Then, the voltage of each unit cell was measured, and this was used as the basis for evaluating the power generation performance. The measured value of the voltage of each cell is expressed in Figure 19 middle. In addition, the average cell voltage and its standard deviation of all the cells are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com