Four-element heat radiator

A radiator and element technology, applied in the field of four-element radiators, can solve problems such as hindering semiconductor thermoelectric devices from using temperature difference to carry out inverse effects, large cooling power consumption, inability to cut off power and heat preservation, and poor thermal conductivity of materials, etc. Effects of improved cooling performance, thermal insulation performance, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

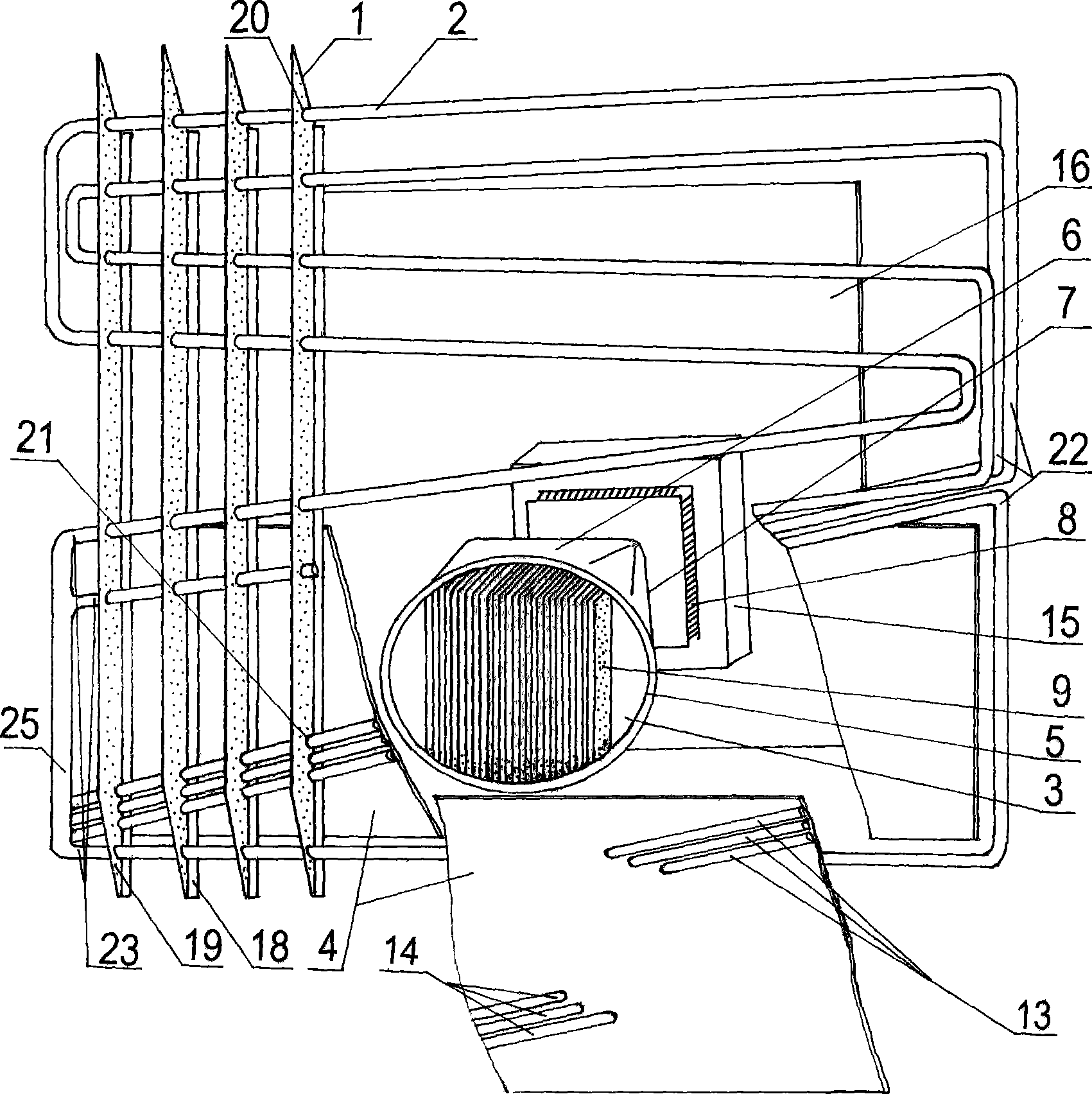

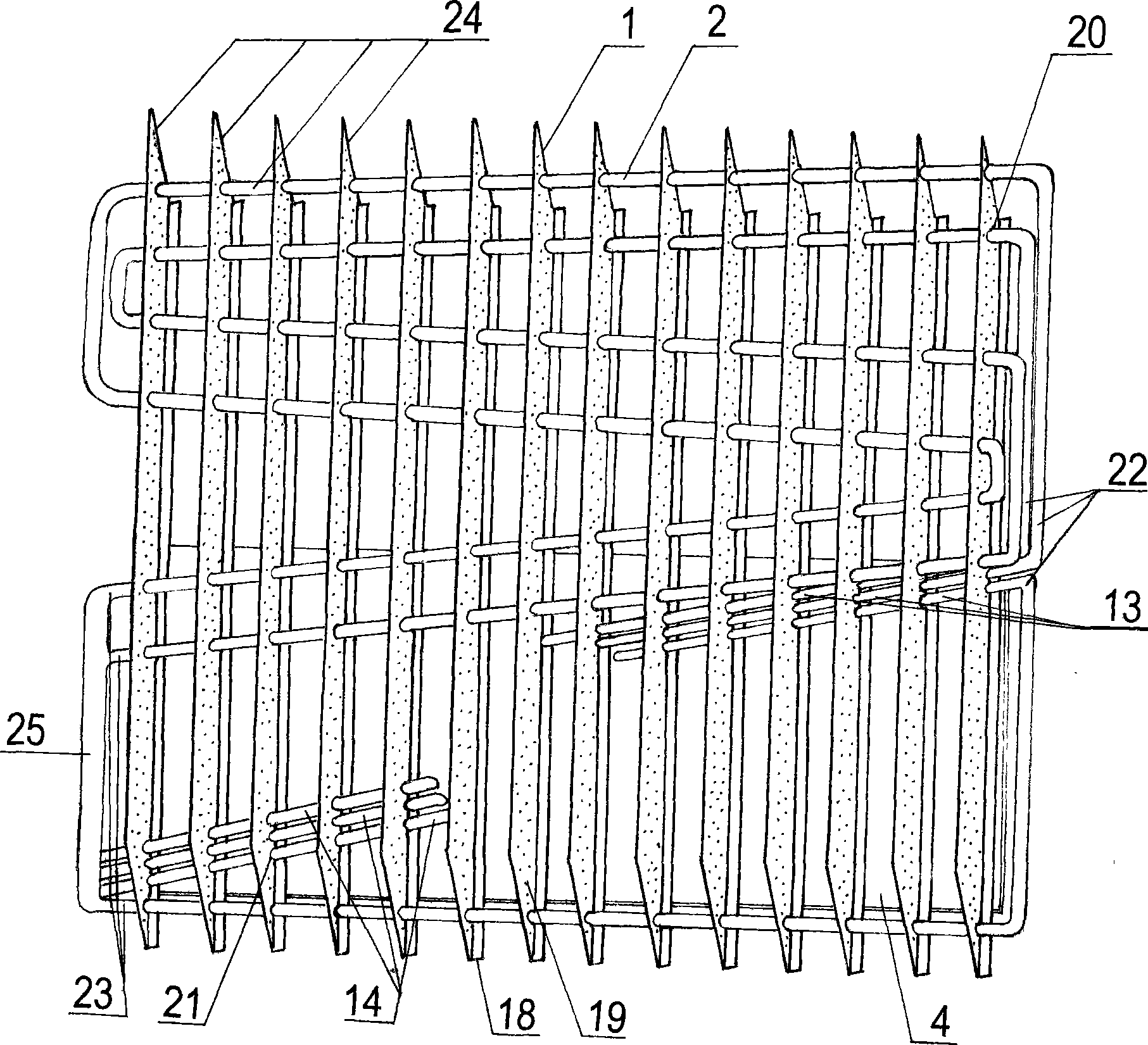

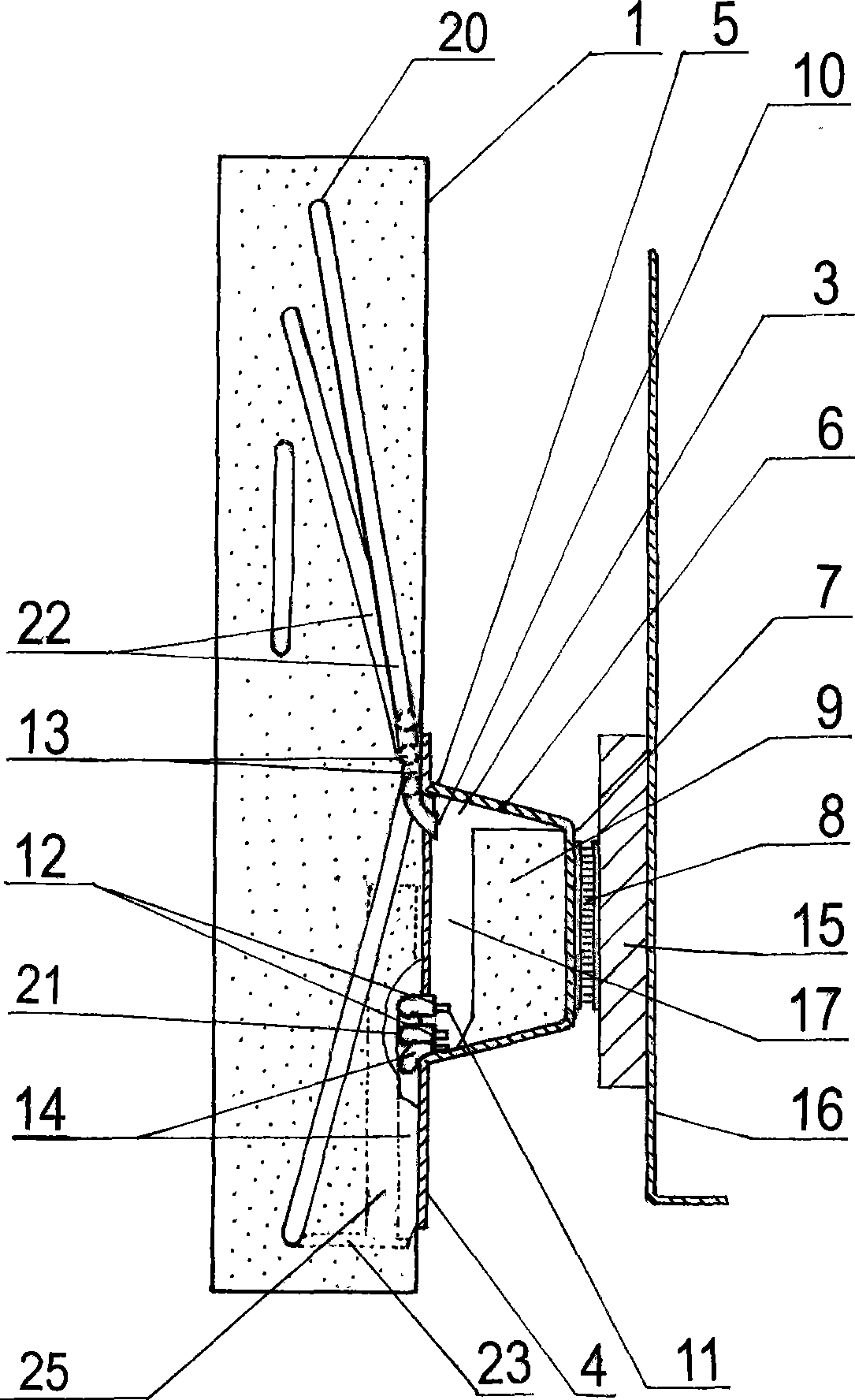

[0013] exist figure 1Middle: The main structure of the four-element radiator is composed of cooling fins (1), circulating heat pipes (2), working fluid heat pump (3), and motherboard (4). The sheet, circulation heat pipe, and motherboard are made of copper or aluminum good heat conductor materials. The working medium heat pump is made of carbon steel and stainless steel with poor thermal conductivity, or it can be made of a combination of poor heat conductor and good heat conductor. The working fluid heat pump is placed on the inner side of the mother board. The shape is a hollow thin-walled boss formed by protruding from the round square platform. The bottom port (5) is round and connected with the mother board. Large top and small boss made of combined materials, the side wall (6) of the boss is made of poor heat conductor, the top is made of good heat conductor, the outer surface of the top is a boss (7), and its area is the same as that of a semiconductor thermoelectric de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com