Wafer stage package cutting method protecting connection pad

A technology of wafer-level packaging and cutting methods, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as manual work, cumbersome packaging process, and unsuitability for mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

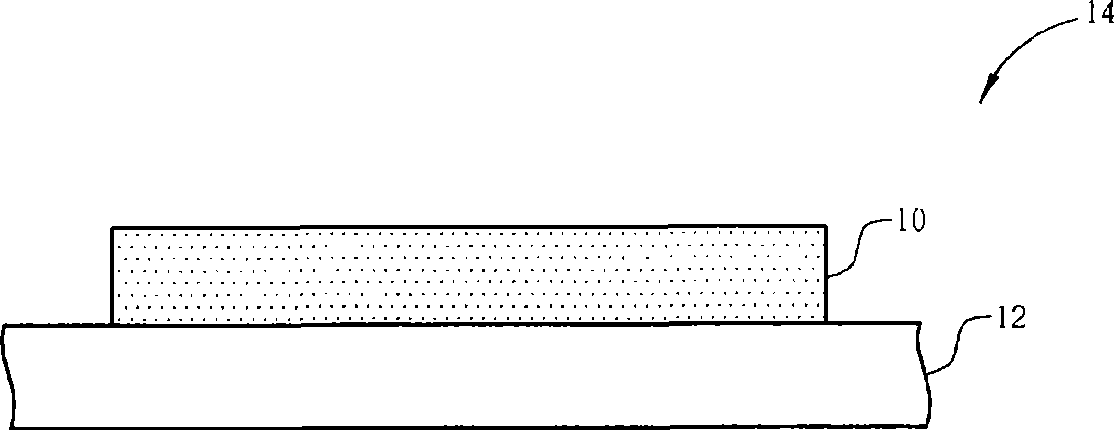

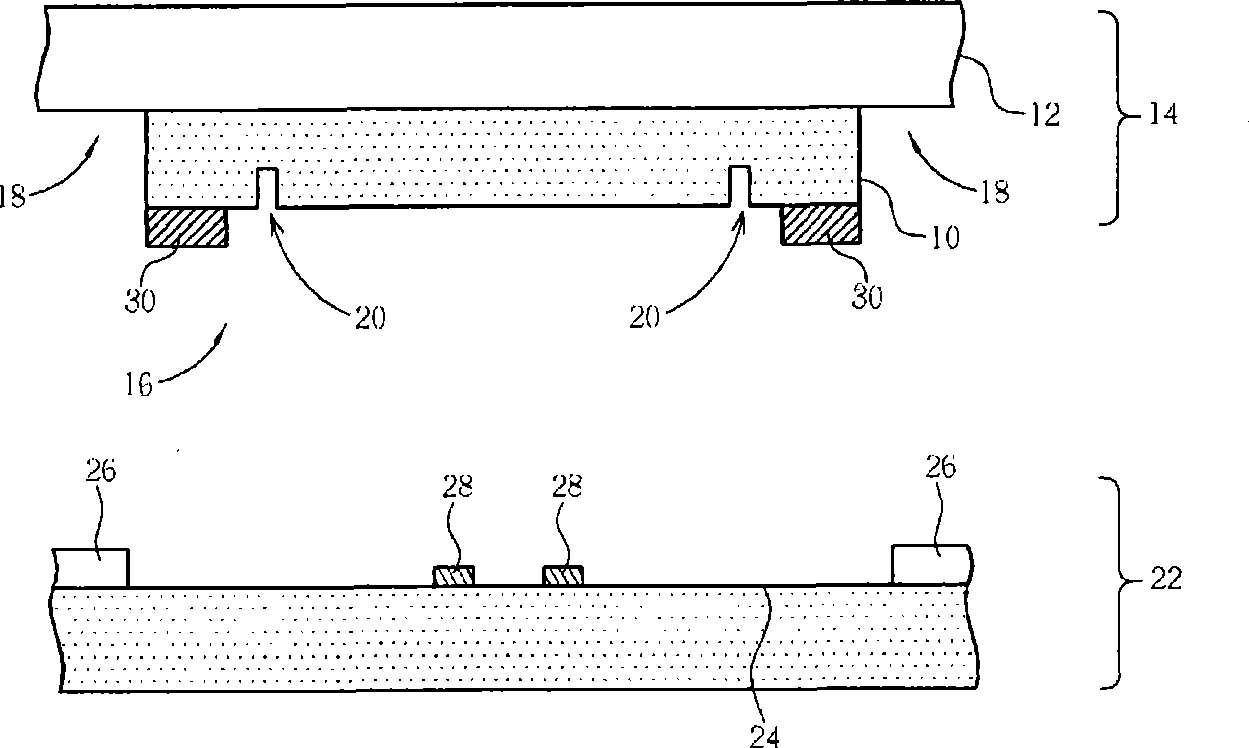

[0024] Please refer to Figure 1 to Figure 6 , Figure 1 to Figure 6 It is a schematic diagram of a wafer dicing manufacturing method according to a preferred embodiment of the present invention. Such as figure 1 As shown, a first wafer 10 and a second wafer 12 are provided through anodic bonding, eutectic bonding, fusion bonding or plasma activation bonding, etc. A known wafer bonding process bonds the first wafer 10 and the second wafer 12 to form a cap wafer 14 . The first wafer 10 can comprise a standard wafer, a silicon wafer, or a wafer with a defined pattern, and the second wafer 12 can be a glass wafer or a packaged wafer, a silicon wafer, or a wafer of other materials. The choice of the chip 14 is not limited to the bonding of two chips as described in this preferred embodiment, and a single standard chip or a silicon chip can also be used as the upper cover chip 14 .

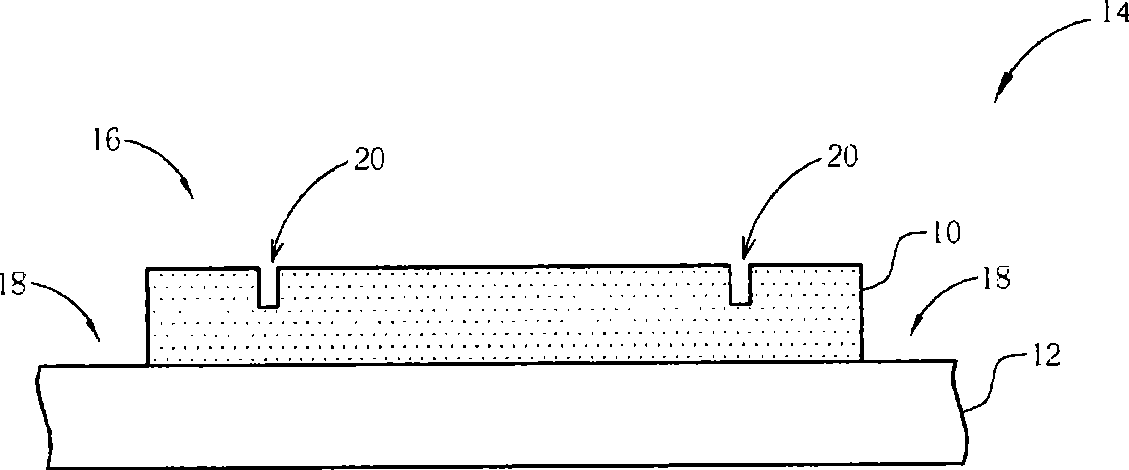

[0025] Such as figure 2 As shown, a surface pattern definition process is performed to simulta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com