Evaporation cooling construction for turbine generator rotor winding

A steam turbine generator and rotor winding technology, applied in the shape/style/structure of winding conductors, manufacturing motor generators, motor components, etc., can solve the problem of high processing cost, difficult industrial production application, corrosion of conductors and insulating materials, etc. problems, to achieve the effect of increasing capacity and efficiency, reducing flow resistance and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

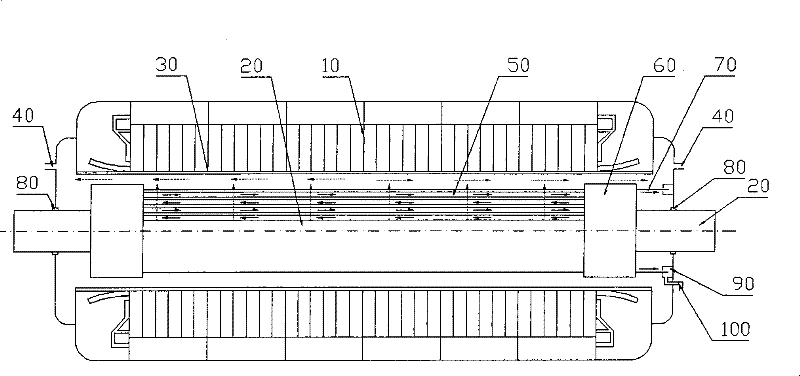

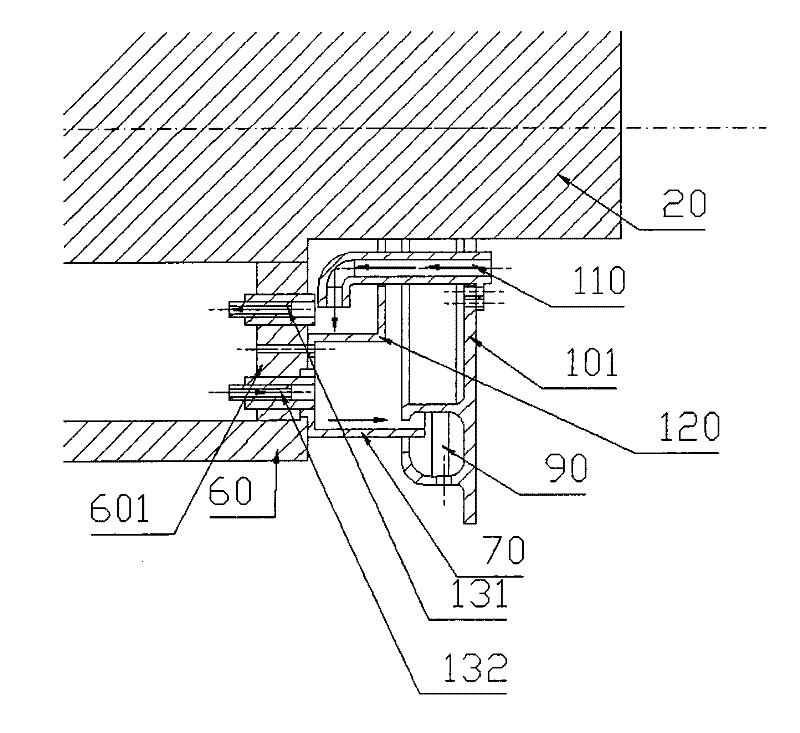

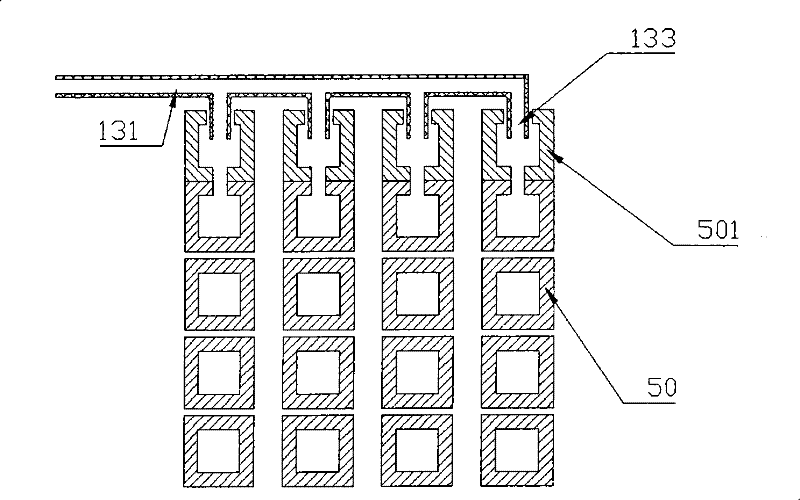

[0015] Overall structure of the present invention is as figure 1 shown. The inner wall of the stator 10 is separated from the rotor 20 by an isolation sleeve 30 , and an air gap is formed between the inner surface of the isolation sleeve 30 and the outer surface of the rotor 20 . The rotor 20 is a hidden pole rotor, and its shape is an elongated cylinder. The circumference of the iron core of the rotor 20 is milled with slots, and the rotor windings 50 are embedded in these slots. The rotor winding 50 is a concentric winding, wound with a hollow copper wire, and the winding is fastened in the slot by a non-magnetic slot wedge 202 . In order to protect and fasten the end of the rotor winding 50, there are guard rings 60 on both sides of the rotor 20, one end of the guard ring 60 is shrunk onto the end of the rotor body, and the other end is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com