Air plasma cutting machine

An air plasma, cutting machine technology, applied in the direction of plasma, plasma welding equipment, electrical components, etc., can solve the problems of large size and weight of the cutting machine, achieve good dynamic characteristics, excellent electrical performance and cutting process performance, and easy to move. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

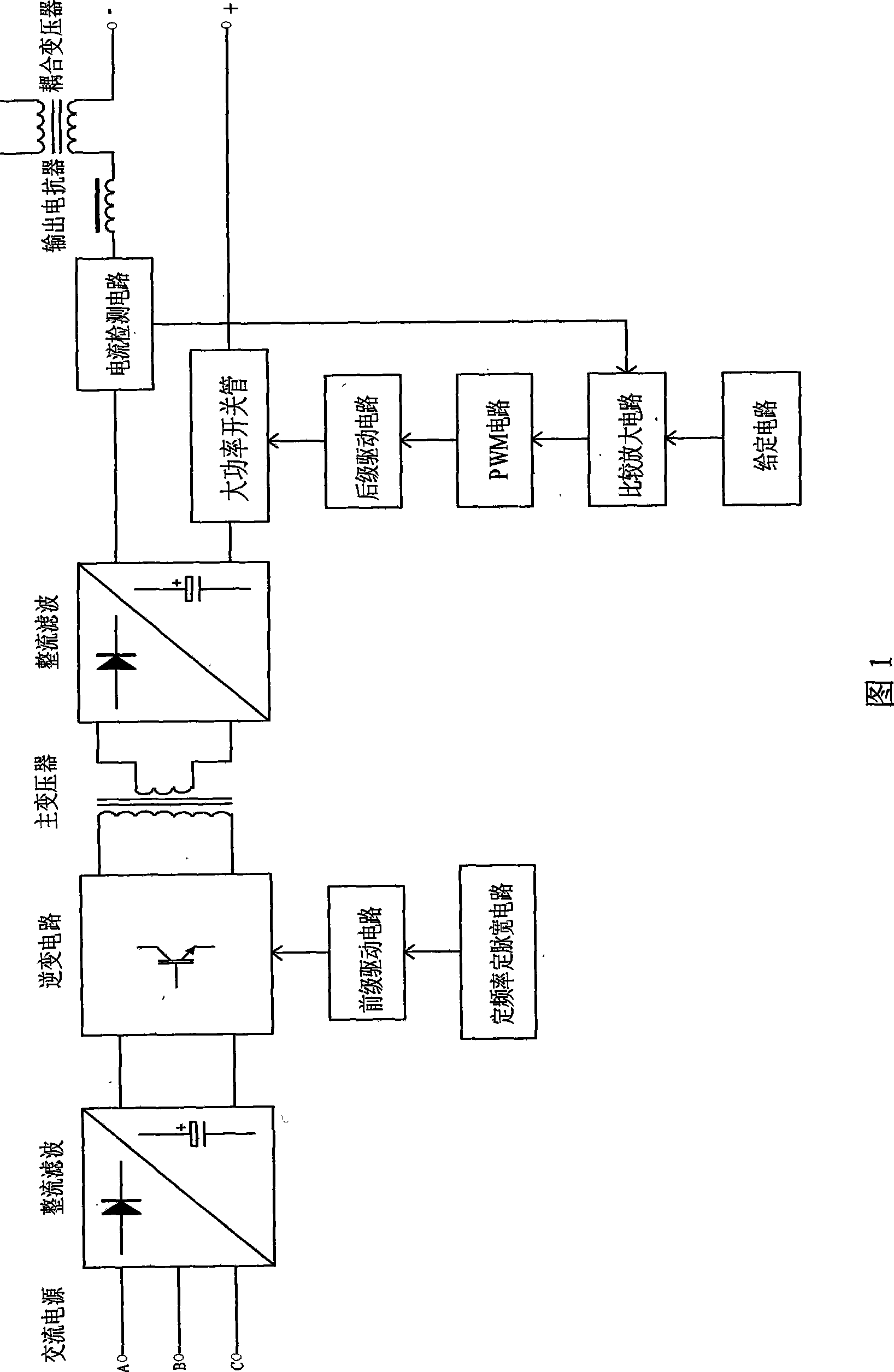

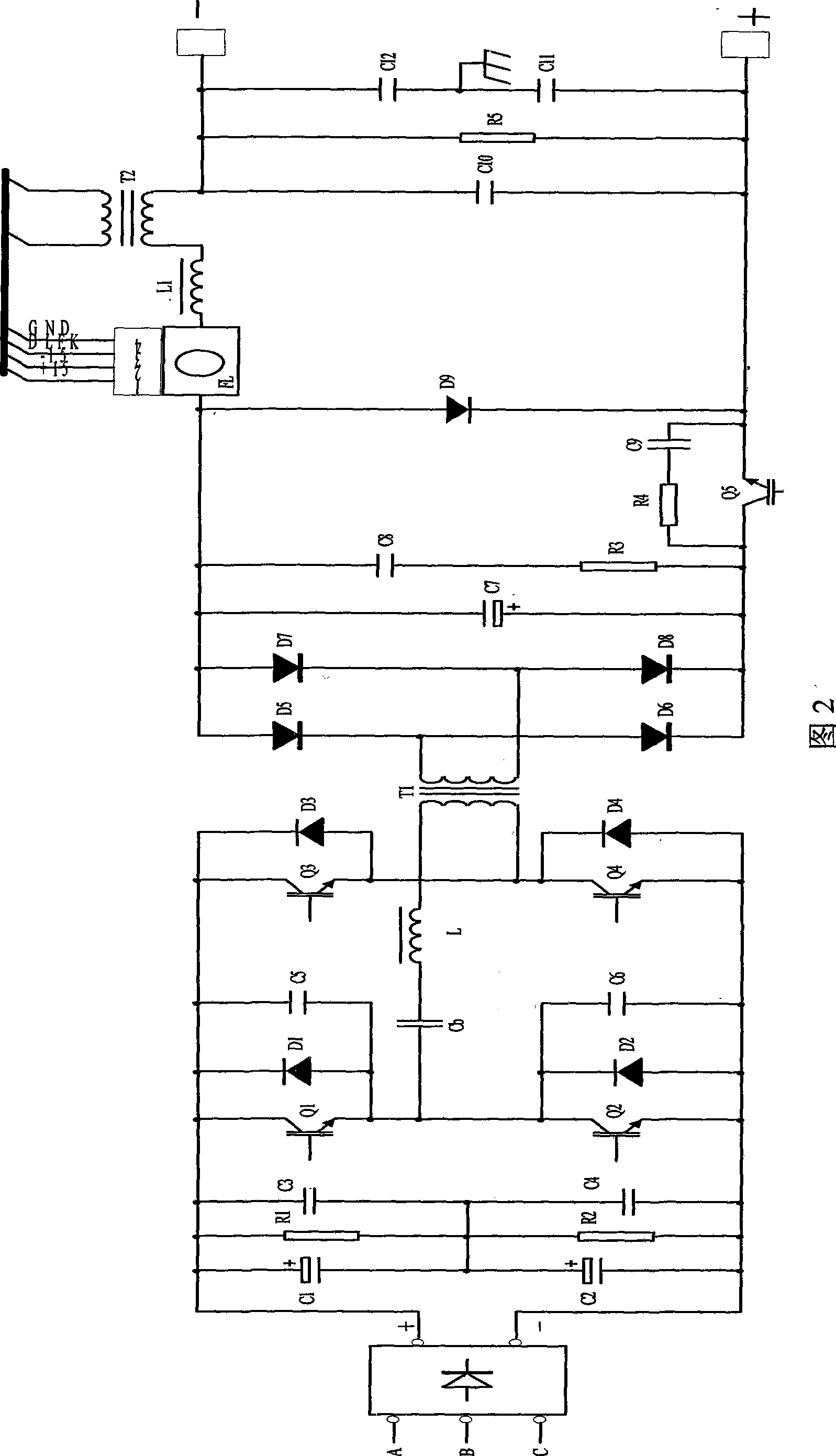

[0015] As shown in Fig. 1, the power supply circuit of the present invention includes a main circuit and a control circuit, and the main circuit is composed of a front-stage main circuit and a rear-stage main circuit. The front-stage main circuit is connected to the left side of the primary side of the main transformer, and the rear-stage main circuit is connected to the right side of the secondary side of the main transformer. The front-stage main circuit is composed of an AC power supply, an input rectification filter circuit and a full-bridge inverter circuit in series. The main circuit of the latter stage is composed of an output rectification filter circuit, a high-power switching circuit and an output reactor. The control circuit is composed of a front-stage control circuit and a post-stage control circuit. Among them, the front-stage control circuit is connected to the full-bridge inverter circuit by the front-stage constant frequency constant pulse width circuit and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com