Chemical wastewater recovery processing technique and apparatus

A technology for chemical wastewater, recycling and treatment, applied in flotation water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. It can achieve the effect of less floor space, improved biodegradability, and compact layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

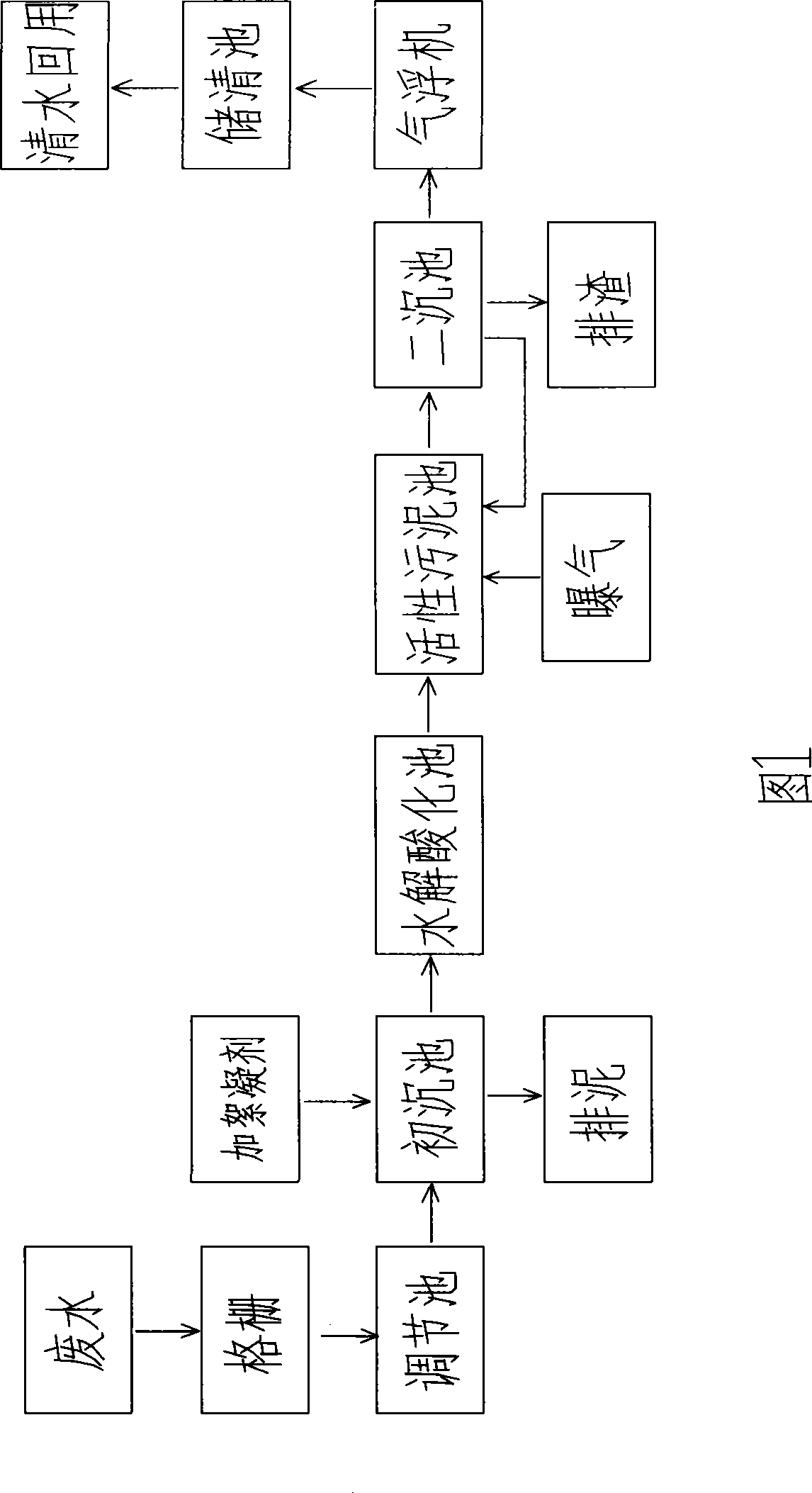

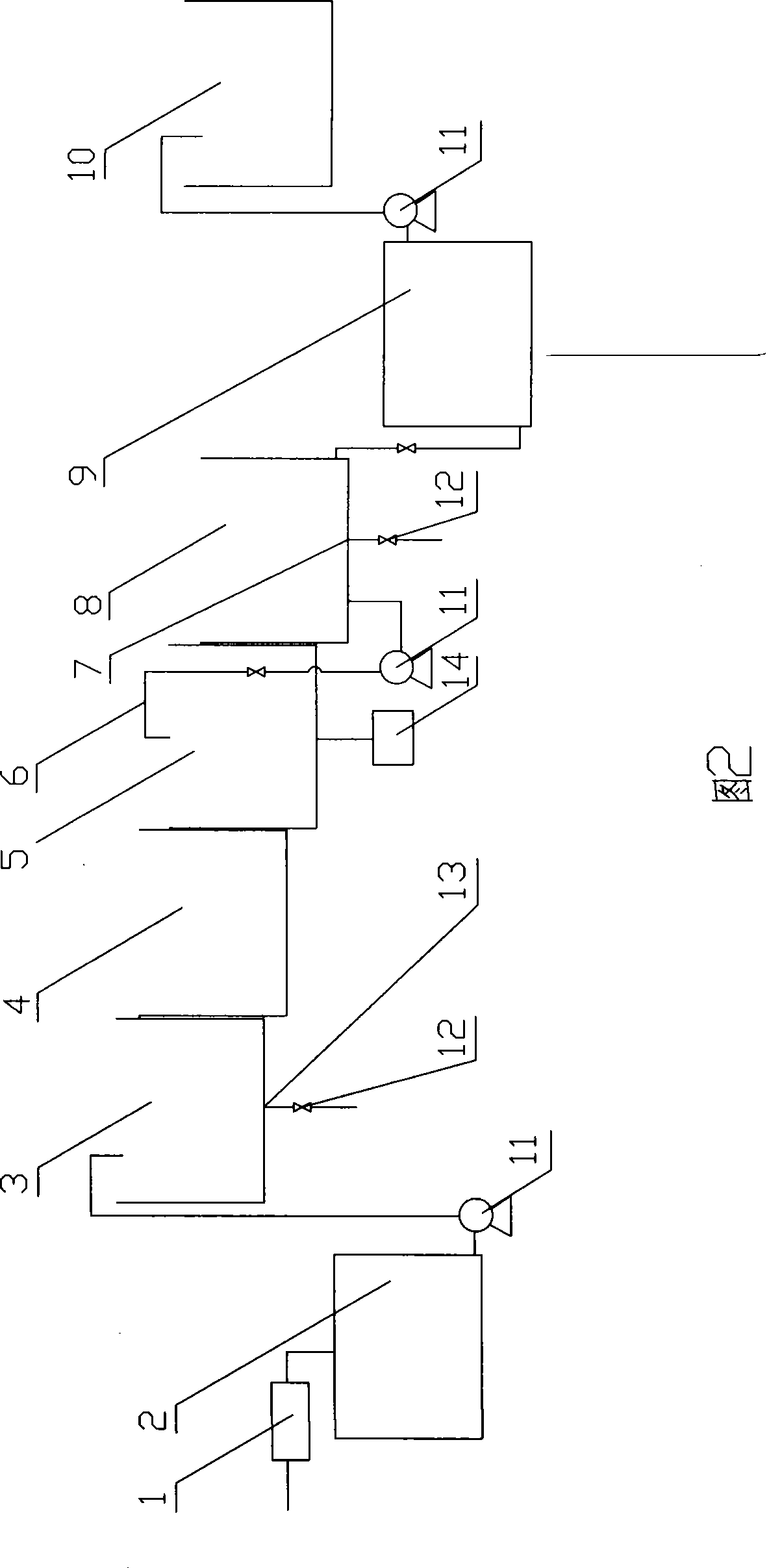

[0032]As shown in Figure 1 and Figure 2, the waste water enters the regulating tank 2 through the grid 1 at 25,000 liters / h, and the pH value of the waste water is adjusted by adding lime water, and the pH value is adjusted to 7.5-8.5, which meets the pH condition of the biochemical treatment. At the same time, the amount and quality of waste water are adjusted; enter the primary sedimentation tank 3, add 5% polyaluminum chloride flocculant from the top, the addition amount is 150kg / d, let it stand for 3-4 hours, and remove the water that is suitable for sedimentation and has a large specific gravity The sludge that settles down is discharged through the mud discharge port 13 at the bottom, and there is a valve 12 on the mud discharge port 13 for control. Ammonia, urea, feces water, decompose ammonia nitrogen and benzene impurities in wastewater, reduce cod value, decompose them from macromolecular state to small molecular state after two days of decomposition, and adjust pH va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com